Method for preparing fried garlic oil seasoning powder through hot-melt extrusion

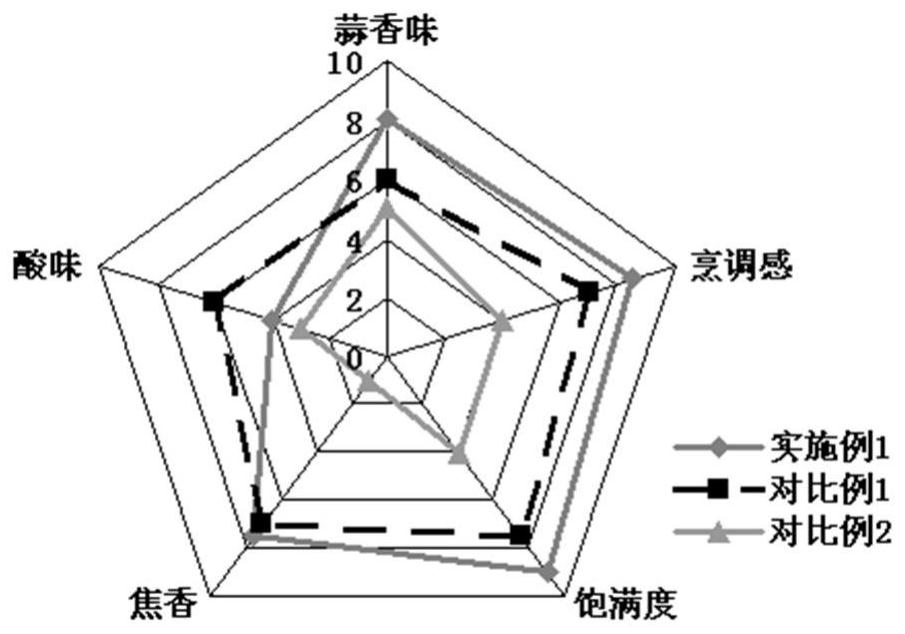

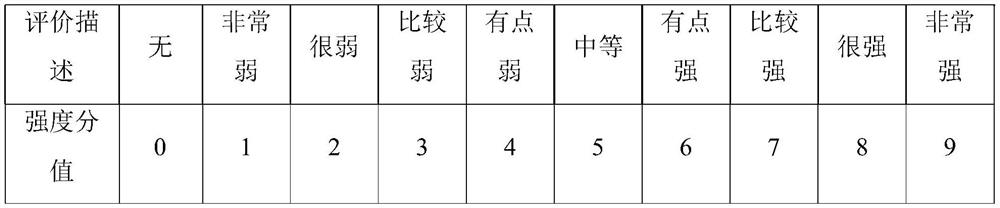

A technology for seasoning powder and fried garlic oil, which is applied in the field of food science, can solve the problems of improving, not performing flavoring and cooking, etc., and achieves the effect of improving the cooking feeling, enhancing the disadvantage of weak smell and strong cooking feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of fried garlic oil seasoning powder, comprising the steps of:

[0036] (1) Peel 200g of garlic, wash it, and dry it; put the garlic into a beater, and it becomes mashed garlic after beating; put the mashed garlic into a stainless steel bucket, add 100g soybean oil, and stir evenly, soak for 18 hours, and get garlic oil mixture.

[0037] (2) Add 1.2g of Tween emulsifier to the garlic oil mixture, undergo high-shear dispersion and emulsification at a speed of 10000r / min, and disperse for 1min to obtain a garlic oil emulsion, then weigh 400g of maltodextrin and 40g of modified starch and garlic oil Emulsions are mixed, and a wet mixer is used to mix to prepare powdery particles, which are powders to be extruded.

[0038] (3) After setting the temperature of each section of the heating zone of the extruder at 80°C-100°C-130°C-140°C-120°C-100°C, after the heating temperature reaches the set temperature, put in the powder to be extruded, Adjust the scr...

Embodiment 2

[0042] A preparation method of fried garlic oil seasoning powder, comprising the steps of:

[0043] (1) Peel 400g of garlic, wash it, and dry it; put the garlic in a beater, and it becomes mashed garlic after beating; put the mashed garlic into a stainless steel bucket, add 150g soybean oil, and stir evenly, soak for 24 hours, and get garlic oil mixture.

[0044] (2) Add 1.8g of Tween emulsifier to the garlic oil mixture, undergo high-shear dispersion and emulsification at a speed of 15000r / min, and disperse for 2 minutes to obtain a garlic oil emulsion, then weigh 500g of maltodextrin and 50g of modified starch and garlic oil Emulsions are mixed, and a wet mixer is used to mix to prepare powdery particles, which are powders to be extruded.

[0045] (3) After setting the temperature of each section of the heating zone of the extruder at 90°C-105°C-120°C-140°C-120°C-105°C, after the heating temperature reaches the set temperature, put in the powder to be extruded, Adjust the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com