Goggles with anti-fog coating and production method of anti-fog coating

An anti-fog coating and goggles technology, applied in the field of goggles, can solve the problems of blocking the field of view, fogging on the mirror surface, affecting the use experience, etc., to avoid self-sliding, improve practicability, and improve the effect of use experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

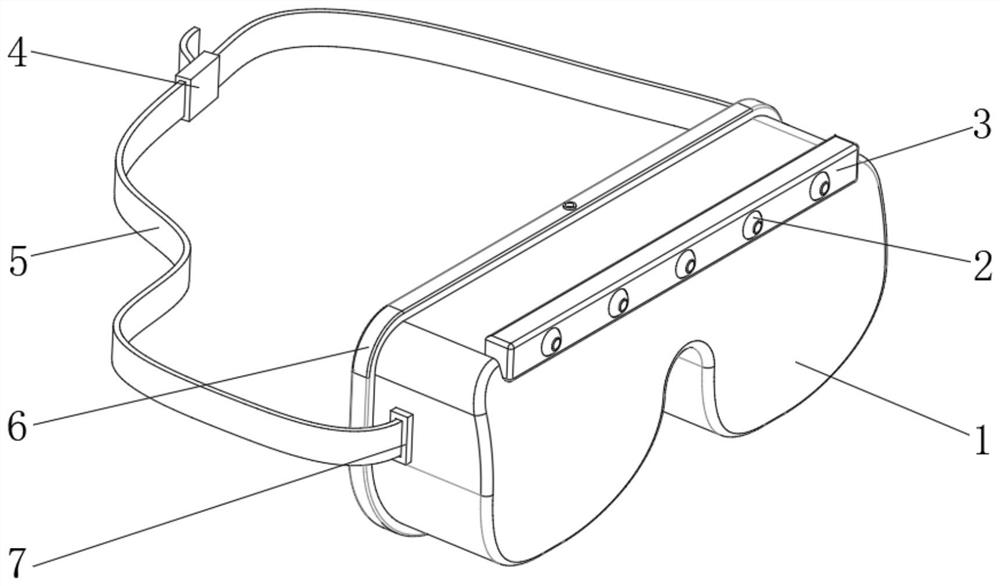

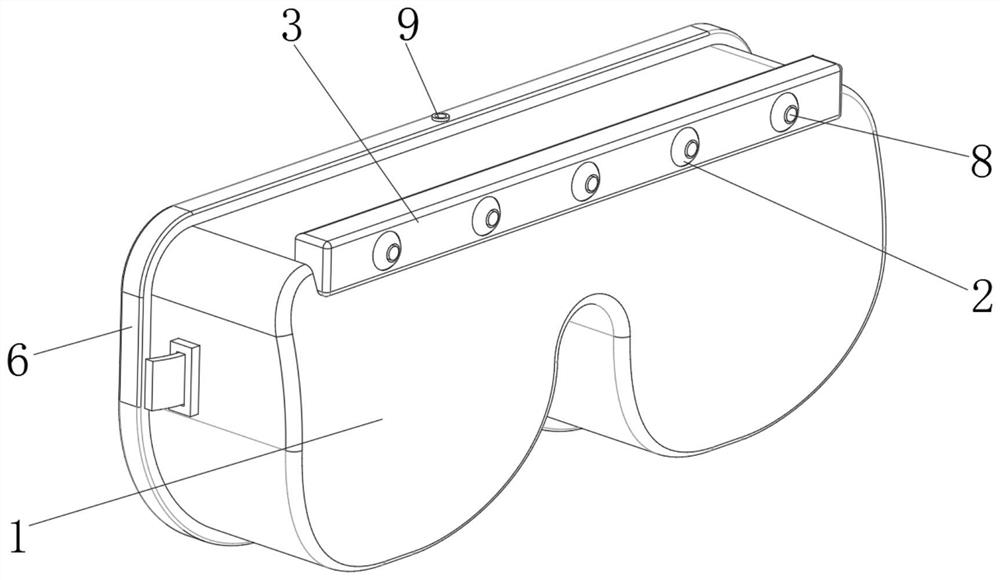

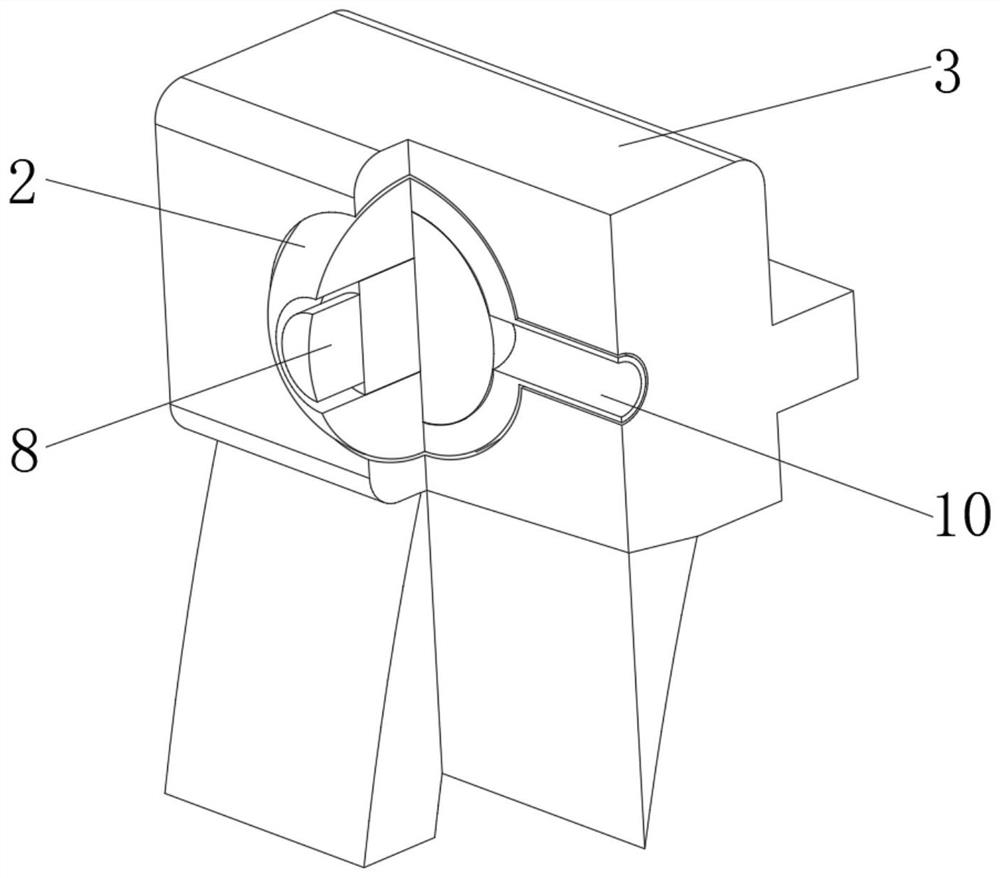

[0036] A goggle with an anti-fog coating such as Figure 1-5 As shown, it includes a main body 1, the mirror surface of the main body 1 is provided with an anti-fog coating, and the raw materials of the anti-fog coating include maleic anhydride grafted polyethylene, silica particle solution, coupling agent, zwitterion Surfactants, polysorbate and organic solvents; the outer walls on both sides of the main body 1 are equipped with straps 5 with adjustable buckles 4 through the fixing seat 7, and the outer walls on one side of the main body 1 are bonded with a belt for improving the tightness of fit. The hollow rubber ring 6; the outer wall of the bottom of the main body 1 is provided with a bridge support mechanism; by setting an anti-fog coating, an effective anti-fog effect can be achieved, the user experience is improved, and it is anti-glare while satisfying anti-fog , wear resistance and water resistance.

[0037] The components of the organic solvent include diisocyanate...

Embodiment 2

[0045] A kind of anti-fog coating production method of the goggles with anti-fog coating, comprises the steps:

[0046] S1: Add diisocyanic acid monomer, hydroxy acrylate and ethyl acetate in proportion to the reaction vessel, stir evenly and heat for 10 minutes, the temperature is controlled at 55-75°C to obtain an organic solvent;

[0047] S2: Slowly add polysorbate, and keep stirring during the addition process to obtain mixed solution A;

[0048] S3: adding a coupling agent to the silica particle solution for preliminary treatment to obtain a mixed solution B;

[0049] S4: Add maleic anhydride-grafted polyethylene and mixed solution B to mixed solution A, and fully stir for 10-15 minutes to obtain mixed solution C;

[0050] S5: Apply the mixed solution C evenly on the mirror surface of the main body 1, put the main body 1 in a curing box for heating and curing, and obtain an anti-fog coating.

[0051] In the step S5, the curing temperature is controlled at 90-130° C., an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com