A kind of preparation method of low reverse osmosis superabsorbent resin

A high-absorbency, resin-based technology, applied in the field of adsorbent resins, can solve the problems of decreased liquid absorption ratio, increased dosage, and reduced reverse osmosis volume, etc., and achieves the effects of fast absorption rate, large absorption volume, and reduced reverse osmosis volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] A method for preparing a low reverse osmosis high-absorbency resin, comprising the following steps:

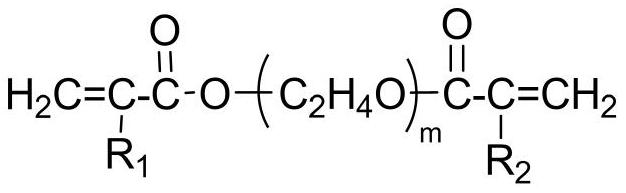

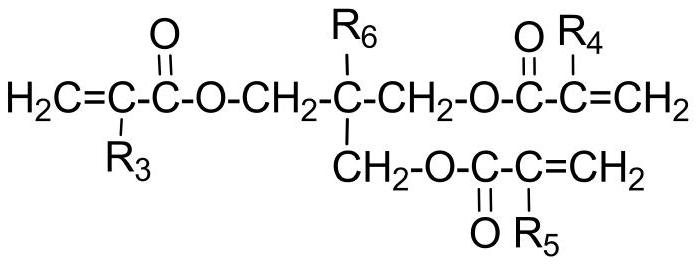

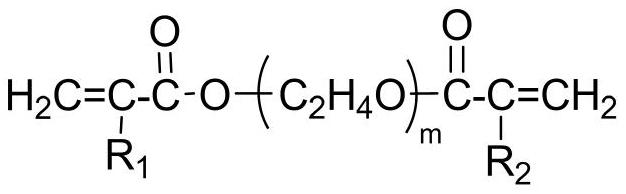

[0061] a) Using acrylic acid and liquid caustic soda as raw materials to prepare a monomer solution, then respectively adding a hydrophilic cross-linking agent, a hydrophobic cross-linking agent and a phase transfer catalyst to the monomer solution, and mixing uniformly to obtain a reaction solution; the hydrophilic cross-linking agent The dosage ratio of linking agent and hydrophobic crosslinking agent is 1:1~10;

[0062] b) controlling the temperature of the reaction solution obtained in step a), and adding a redox initiator to carry out a polymerization reaction to obtain a superabsorbent resin gel;

[0063] c) granulating the superabsorbent resin gel, and adding a surfactant and caustic soda during the granulation process;

[0064] d) After the high-absorbent resin gel granulation is completed, it is dried, pulverized, screened, and surface treated in sequence to o...

Embodiment 2

[0079] A method for preparing a low reverse osmosis high-absorbency resin, comprising the following steps:

[0080] a) Using acrylic acid and liquid caustic soda as raw materials to prepare a monomer solution, then respectively adding a hydrophilic cross-linking agent, a hydrophobic cross-linking agent and a phase transfer catalyst to the monomer solution, and mixing uniformly to obtain a reaction solution; the hydrophilic cross-linking agent The dosage ratio of linking agent and hydrophobic crosslinking agent is 1:3;

[0081] b) controlling the temperature of the reaction solution obtained in step a), and adding a redox initiator to carry out a polymerization reaction to obtain a superabsorbent resin gel;

[0082] c) granulating the superabsorbent resin gel, and adding a surfactant and caustic soda during the granulation process;

[0083] d) After the high-absorbent resin gel granulation is completed, it is dried, pulverized, screened, and surface treated in sequence to obta...

Embodiment 3

[0098] A method for preparing a low reverse osmosis high-absorbency resin, comprising the following steps:

[0099] a) Using acrylic acid and liquid caustic soda as raw materials to prepare a monomer solution, then respectively adding a hydrophilic cross-linking agent, a hydrophobic cross-linking agent and a phase transfer catalyst to the monomer solution, and mixing uniformly to obtain a reaction solution; the hydrophilic cross-linking agent The dosage ratio of linking agent and hydrophobic crosslinking agent is 1:7;

[0100] b) controlling the temperature of the reaction solution obtained in step a), and adding a redox initiator to carry out a polymerization reaction to obtain a superabsorbent resin gel;

[0101] c) granulating the superabsorbent resin gel, and adding a surfactant and caustic soda during the granulation process;

[0102] d) After the high-absorbent resin gel granulation is completed, it is dried, pulverized, screened, and surface treated in sequence to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com