Water-absorbing resin

A water-absorbing, resin-based technology, applied in absorbent pads, other chemical processes, bandages, etc., can solve problems such as impaired hand feel, difficult absorbent body absorption performance and hand feel, and inability to meet absorption performance, and achieve the effect of reducing reverse osmosis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

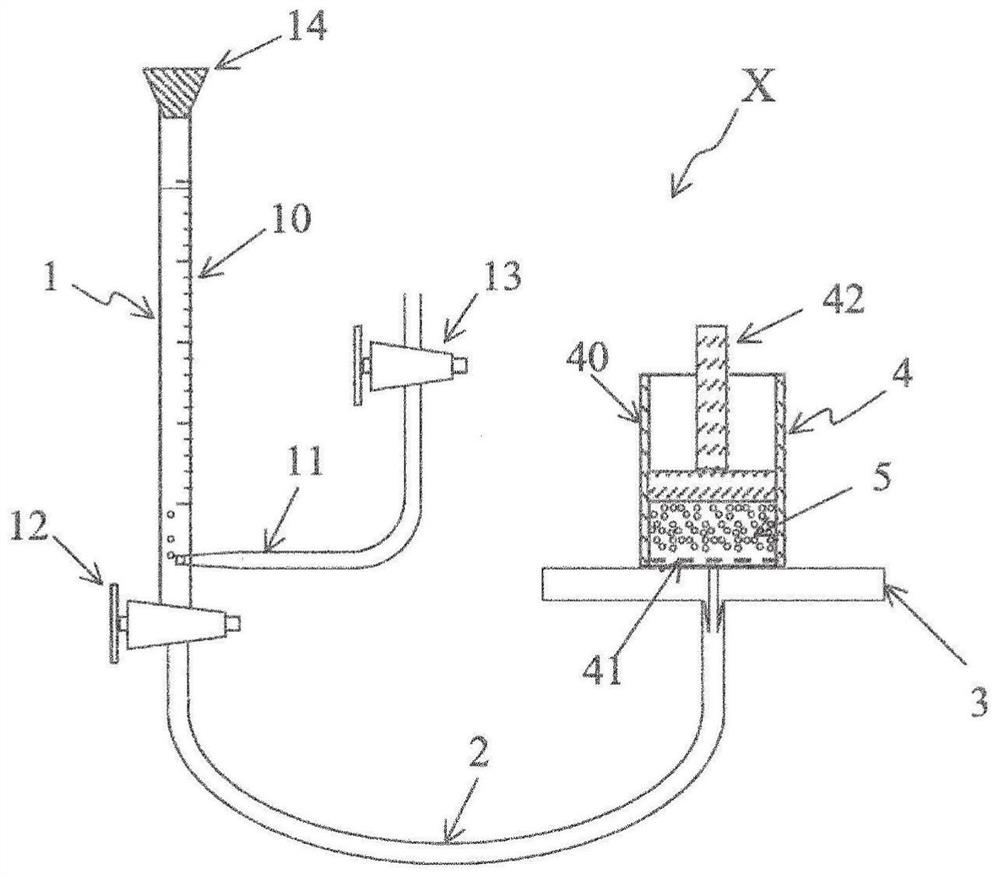

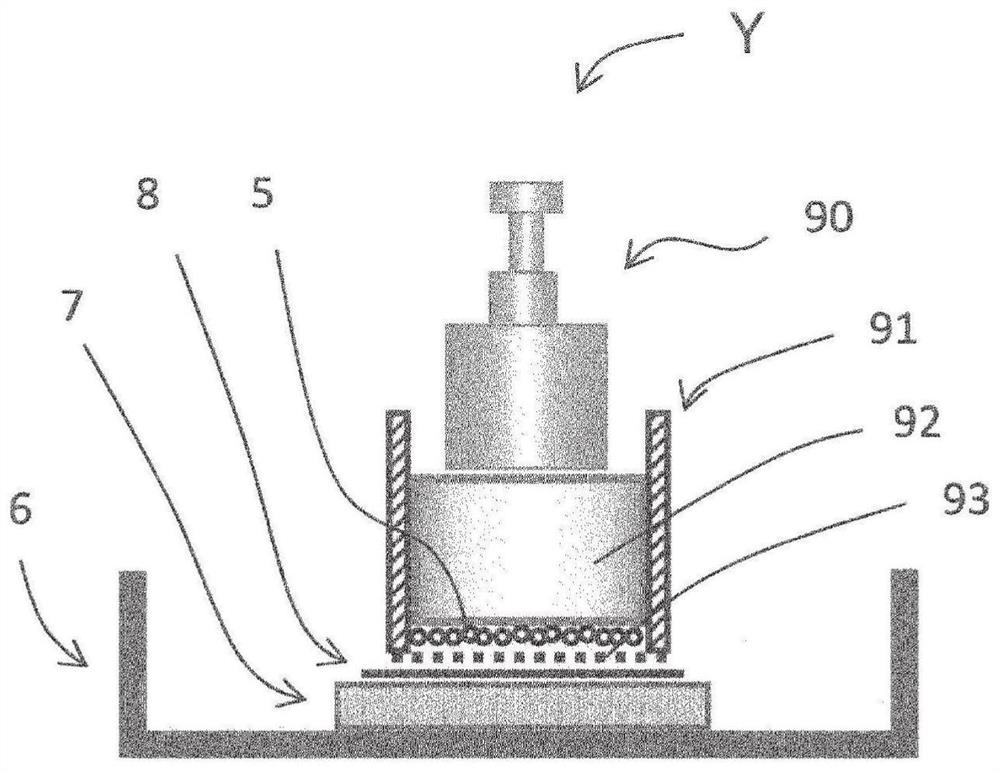

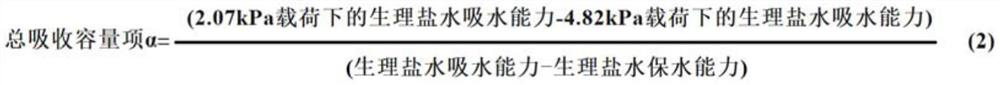

Image

Examples

Embodiment

[0132] Hereinafter, examples are shown and the present invention will be described in more detail, but the present invention is not limited to the following examples.

[0133]

[0134] [Evaluation test of water-absorbent resin]

[0135] The water-absorbent resins obtained in the following examples and comparative examples were evaluated in various tests shown below. Hereinafter, each test method is demonstrated.

[0136] 1) Absorption capacity of normal saline

[0137] In a 500 mL capacity beaker, 500 g of a 0.9% by mass sodium chloride aqueous solution (physiological saline) was weighed, and 2.0 g of the water-absorbent resin was dispersed without forming lumps while stirring at 600 r / min. Stirring was continued for 60 minutes to fully swell the water-absorbent resin. Then, the mass Wa (g) of a 200mmφ standard sieve with a mesh size of 75 μm is measured in advance, and the contents of the above-mentioned beaker are filtered using the standard sieve. In the state, let it...

Embodiment 1

[0180]Prepare a round-bottomed cylinder with an inner diameter of 110 mm and a capacity of 2 L equipped with a reflux condenser, a dropping funnel, a nitrogen gas introduction pipe, and a stirring blade with two stages of 4 pitched blades with a blade diameter of 50 mm as an agitator. Detachable flask. In this flask, 300 g of n-heptane was weighed as a hydrocarbon dispersion medium, and 0.62 g of a maleic anhydride-modified ethylene-propylene copolymer (Mitsui Chemicals, Inc., Hi-WAX1105A) was added as a polymeric dispersant. Heat to dissolve while stirring, then cool to 50°C.

[0181] On the other hand, 78 g (0.87 moles) of an 80 mass % acrylic acid aqueous solution was weighed in a 500 mL Erlenmeyer flask, and while cooling from the outside, 120.6 g of a 22.4 mass % sodium hydroxide aqueous solution was added dropwise for neutralization, and then Add 1.170 g of hydroxyethylcellulose (Sumitomo Seika Co., Ltd., HEC AW-15F) as a thickener, 0.055 g (0.203 mmol) of potassium per...

Embodiment 2

[0185] Prepare a round-bottomed cylinder with an inner diameter of 110 mm and a capacity of 2 L equipped with a reflux condenser, a dropping funnel, a nitrogen gas introduction pipe, and a stirring blade with two stages of 4 pitched blades with a blade diameter of 50 mm as an agitator. Detachable flask. In this flask, 300 g of n-heptane was weighed as a hydrocarbon dispersion medium, and 0.52 g of a maleic anhydride-modified ethylene-propylene copolymer (Mitsui Chemicals, Inc., Hi-WAX1105A) was added as a polymeric dispersant. Heat to dissolve while stirring, then cool to 50°C.

[0186] On the other hand, 65 g (0.72 moles) of an 80 mass % acrylic acid aqueous solution was weighed in a 500 mL Erlenmeyer flask, and while cooling from the outside, 100.5 g of a 22.4 mass % sodium hydroxide aqueous solution was added dropwise for neutralization, and then Add 0.065 g of hydroxyethyl cellulose (Sumitomo Seika Co., Ltd., HEC AW-15F) as a thickener, 0.046 g (0.170 mmol) of potassium p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com