Down-the-hole drill bit coated with diamond layer by laser 3D printing method and preparation method of down-the-hole drill bit

A technology of diamond layer and printing method, which is applied to drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of reducing the drilling efficiency of the drill bit, shortening the service life of the drill bit, wear resistance and other problems, so as to improve the drilling efficiency, High utilization rate of material forming and sintering, and the effect of improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

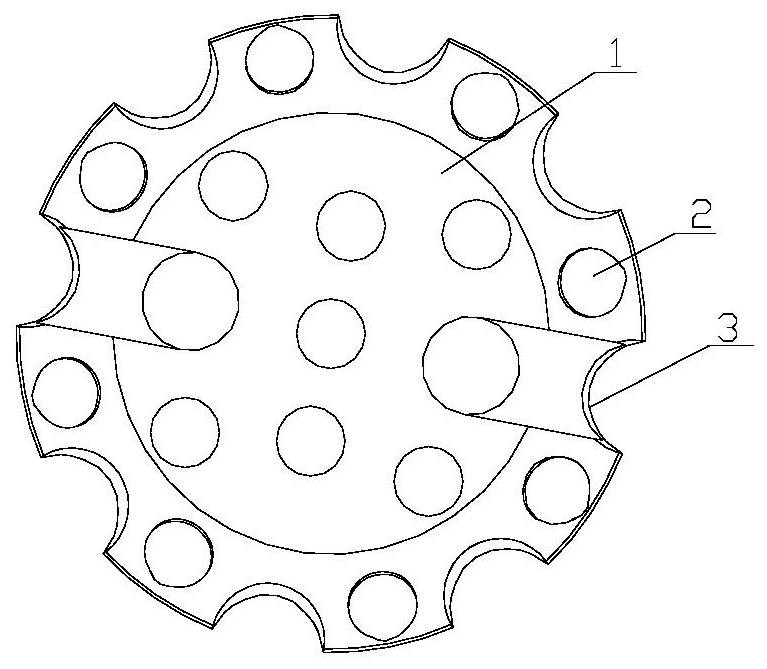

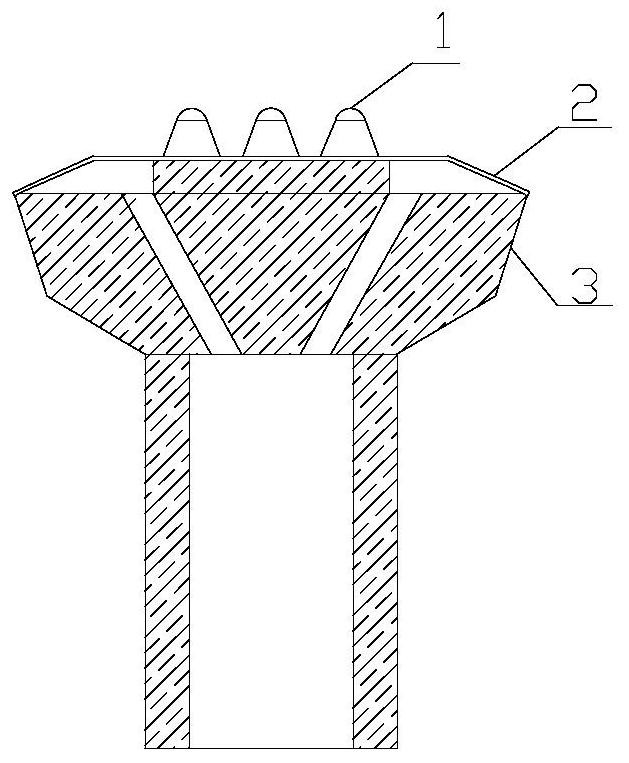

[0029] Such as figure 1 , 2 As shown, the cemented carbide down-the-hole drill bit coated with diamond layer by laser 3D printing method includes three parts: the drill body, the working surface of the warehouse body impregnated with diamond layer, and the cemented carbide button. The impregnated diamond layer coated on the working face of the drill body has a thickness of 5mm, the volume fraction of CoCrWMo alloy is 75%, and the volume fraction of diamond is 25%. The raw material CoCrWMo pre-alloyed powder is used, the composition mass ratio is Co82%, Cr6%, W7%, Mo5%, and the powder particle size is 0.038-0.044mm (300 / 325 mesh). The diamond particle size used is 0.12-0.15 mm (100 / 120 mesh).

[0030] Its production process is as follows:

[0031] Step 1: Prepare CoCrWMo pre-alloyed powder and diamond, wherein the composition mass ratio of CoCrWMo pre-alloyed powder is Co82%, Cr6%, W7%, Mo5%, and the particle size is 0.038~0.044mm (300 / 325 mesh); the diamond particle size is...

Embodiment 2

[0042] Such as figure 1 ,2 As shown, the cemented carbide down-the-hole drill bit coated with diamond layer by laser 3D printing method includes three parts: the drill body, the working surface of the warehouse body impregnated with diamond layer, and the cemented carbide button. The impregnated diamond layer coated on the working face of the drill body has a thickness of 5mm, the volume fraction of CoCrWMo alloy is 85%, and the volume fraction of diamond is 15%. The raw material CoCrWMo pre-alloyed powder is used, the composition mass ratio is Co84%, Cr3%, W10%, Mo3%, and the powder particle size is 0.044-0.053mm (270 / 300 mesh). The diamond particle size used is 0.104-0.124mm (120 / 140 mesh).

[0043] Its production process is as follows:

[0044] Step 1: Prepare CoCrWMo pre-alloyed powder and diamond, wherein the composition mass ratio of CoCrWMo pre-alloyed powder is Co84%, Cr3%, W10%, Mo3%, and the particle size is 0.044~0.053mm (270 / 300 mesh); the diamond particle size i...

Embodiment 3

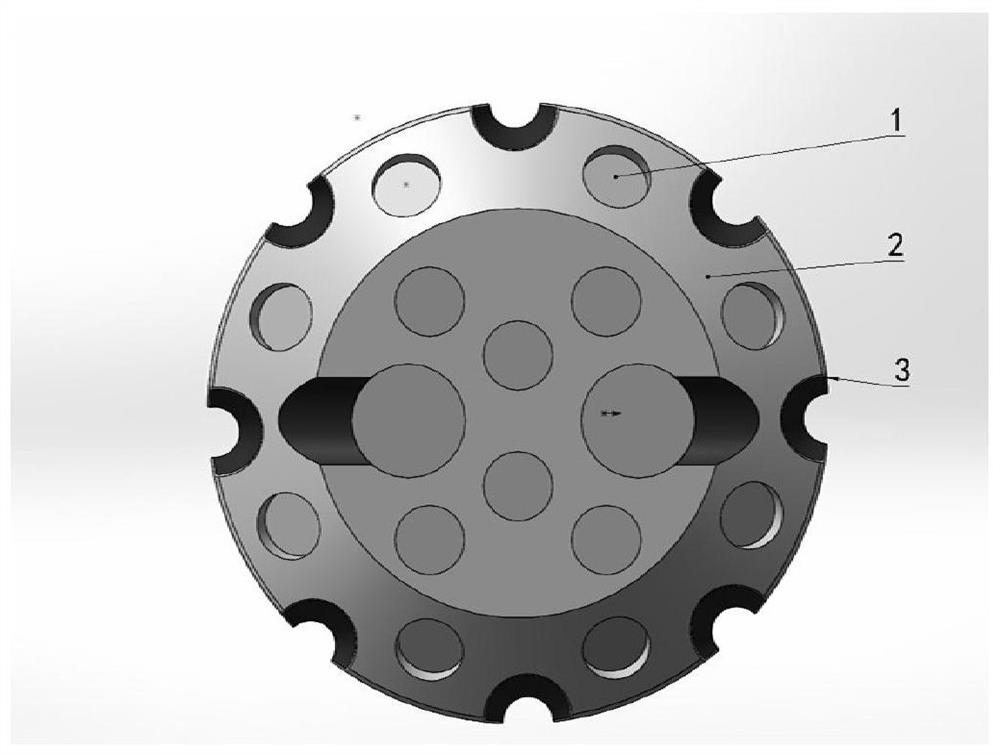

[0053] Such as image 3 , 4 As shown, the diamond layer-coated composite down-the-hole drill bit by the laser 3D printing method includes three parts: the drill body, the working surface of the reservoir body impregnated with the diamond layer, and the composite sheet button. The impregnated diamond layer coated on the working face of the drill bit magazine has a thickness of 5mm, the volume fraction of CoCrWMo alloy is 75%, and the volume fraction of diamond is 25%. The raw material CoCrWMo pre-alloyed powder is used, the composition mass ratio is Co82%, Cr6%, W7%, Mo5%, and the powder particle size is 0.038-0.044mm (300 / 325 mesh). The diamond particle size used is 0.12-0.15 mm (100 / 120 mesh).

[0054] Its production process is as follows:

[0055] Step 1: Prepare CoCrWMo pre-alloyed powder and diamond, wherein the composition mass ratio of CoCrWMo pre-alloyed powder is Co82%, Cr6%, W7%, Mo5%, and the particle size is 0.038~0.044mm (300 / 325 mesh); the diamond particle size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com