Low-temperature auxiliary electronic jet printing method

An auxiliary electric and low-temperature technology, which is applied in the directions of processing and manufacturing, coating devices, and additive processing, can solve the problems of jet droplets deviating from the expected trajectory, destroying the stability of the electric fluid, and slow charge decay rate, etc., to achieve accurate and Efficient cooling, improved stability, and reduced reflow effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

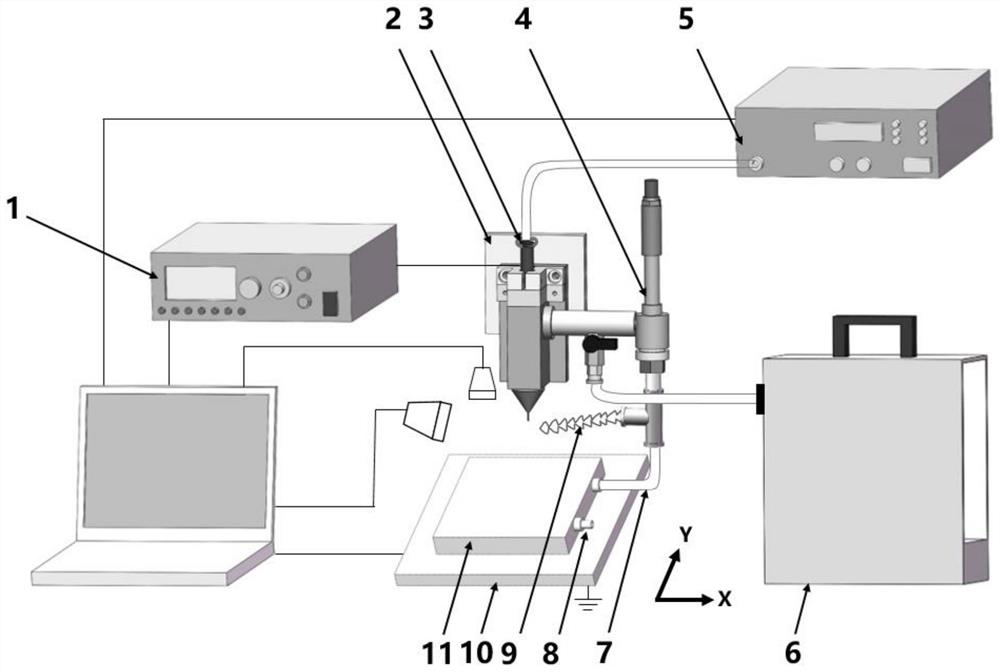

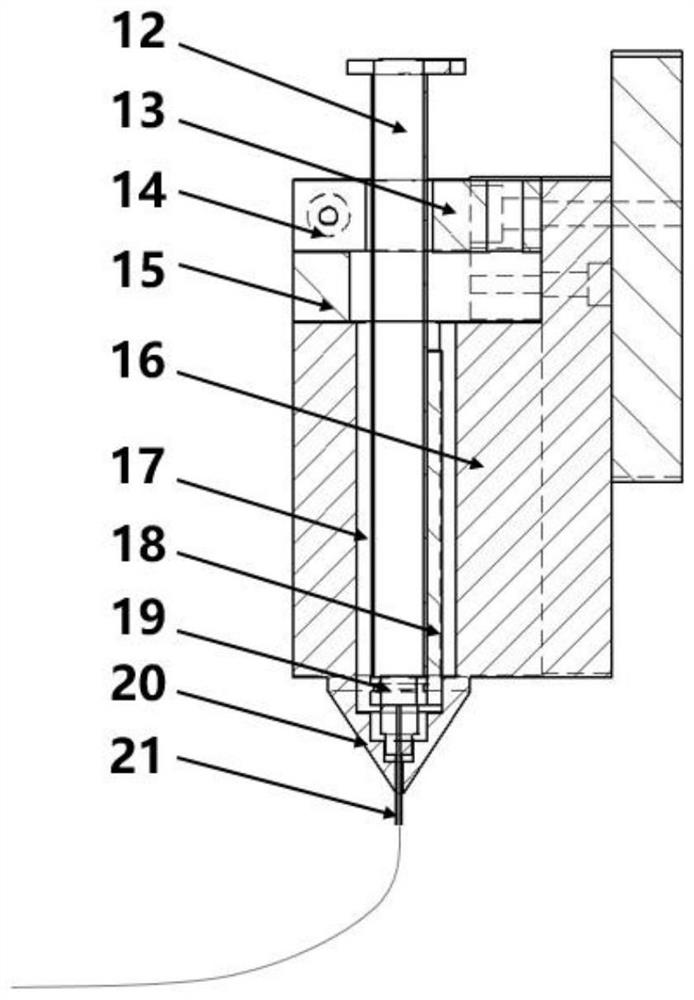

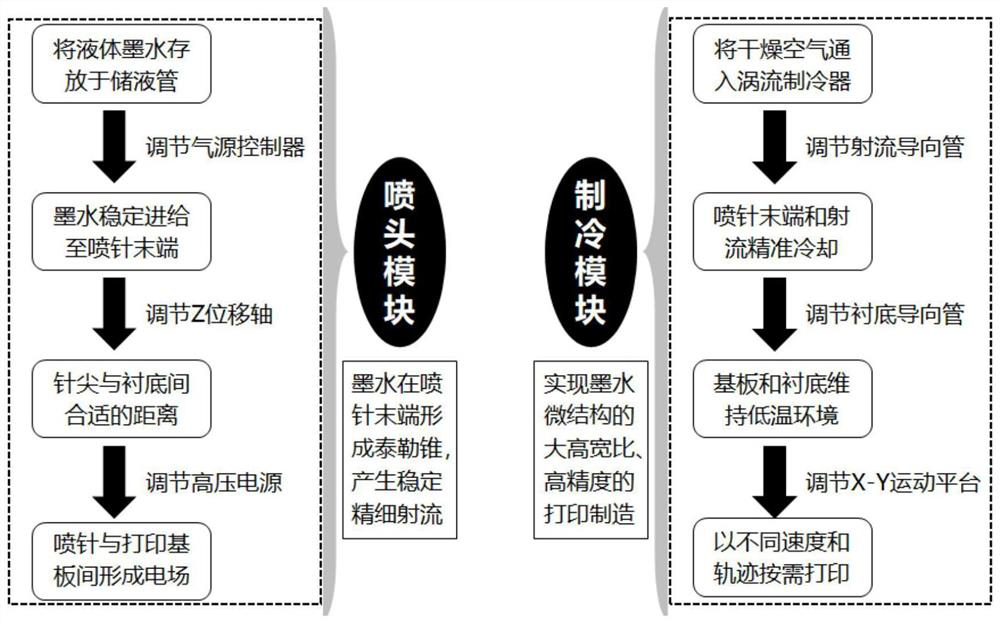

[0027] The present invention will be described in detail below in combination with technical solutions and accompanying drawings. A low-temperature assisted electrojet printing method in the embodiment is realized by using a low-temperature electrofluid jet printing nozzle device, and the device is mainly composed of two parts: an electro-fluid nozzle module and a jet printing refrigeration module.

[0028] The nozzle module is as figure 1 and figure 2As shown, it includes multi-waveform high-voltage power supply 1, Z displacement axis 2, cap 3, air source controller 5, liquid storage pipe 12, outlet port 13, fixing block 14, shading block 15, nozzle body 16, potting port 17, High-voltage cable 18, metal base 19, conical cap 20, and insulating spray needle 21; the structure of the spray needle is composed of a metal base 19 and an insulating spray needle 21, and the material of the metal base 19 is aluminum alloy, with a length of about 4mm , the outer diameter of the insul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Inner diameter range | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com