Water reducing agent composition for coal mine paste filling as well as preparation method and application of water reducing agent composition

A technology of paste filling and composition, which is applied in the field of paste filling, can solve the problems of poor collapse protection effect of gangue paste filling materials, failure to meet construction design requirements, and inability to effectively reduce water consumption, etc., so as to improve the wrapping performance and Flow performance, improvement of wrapping performance and flow performance, and rapid increase in strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

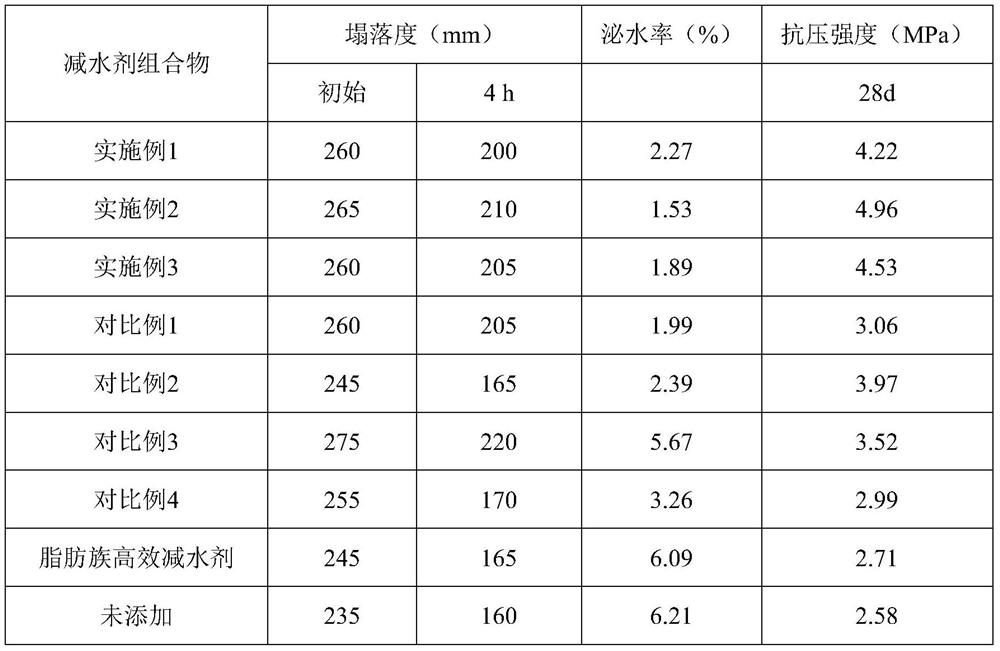

Examples

Embodiment 1

[0036] This example provides a water reducer composition for coal mine paste filling, and the ratio of each component by mass fraction is as follows: aliphatic high-efficiency water reducer 45%, reinforcing agent 5%, dispersant 0.2%, water retention agent 0.01% , and the balance is water.

[0037] Specifically, the above-mentioned enhancer is compounded by ethylene glycol and sodium thiosulfate decahydrate at a mass ratio of 1:9, the above-mentioned dispersant is CPE1500, and the above-mentioned water-retaining agent is HPC.

[0038] The preparation method of this water reducer composition comprises the following steps:

[0039] Mix the components of the enhancer evenly,

[0040] Provide the formula amount of water, add aliphatic high-efficiency water reducer, reinforcing agent, dispersant, and water retaining agent in sequence, and mix evenly to obtain the water reducer composition.

Embodiment 2

[0042] This example provides a water reducer composition for coal mine paste filling, and the proportion of each component according to mass fraction is as follows: aliphatic high-efficiency water reducer 55%, reinforcing agent 9%, dispersant 0.4%, water retention agent 0.02% , and the balance is water.

[0043] Specifically, the above-mentioned enhancer is compounded by ethylene glycol and sodium thiosulfate decahydrate at a mass ratio of 1:9, the above-mentioned dispersant is CPE1500, and the above-mentioned water-retaining agent is HPC.

[0044] The preparation method of this water reducer composition comprises the following steps:

[0045] Mix the components of the enhancer evenly,

[0046] Provide the formula amount of water, add aliphatic high-efficiency water reducer, reinforcing agent, dispersant, and water retaining agent in sequence, and mix evenly to obtain the water reducer composition.

Embodiment 3

[0048] This example provides a water reducer composition for coal mine paste filling, and the ratio of each component by mass fraction is as follows: aliphatic high-efficiency water reducer 53%, reinforcing agent 6%, dispersant 0.3%, water retention agent 0.015% , and the balance is water.

[0049] Specifically, the above-mentioned enhancer is compounded by ethylene glycol and sodium thiosulfate decahydrate at a mass ratio of 1:9, the above-mentioned dispersant is CPE1500, and the above-mentioned water-retaining agent is HPC.

[0050] The preparation method of this water reducer composition comprises the following steps:

[0051] Mix the components of the enhancer evenly,

[0052] Provide the formula amount of water, add aliphatic high-efficiency water reducer, reinforcing agent, dispersant, and water retaining agent in sequence, and mix evenly to obtain the water reducer composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com