Magnesium current stabilizer for tundish and preparation method thereof

A current stabilizer and tundish technology, applied in the field of refractory materials, can solve the problems of low cost and short cycle, and achieve the effects of reducing production cycle, improving labor efficiency, and reducing the hydration rate of magnesia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

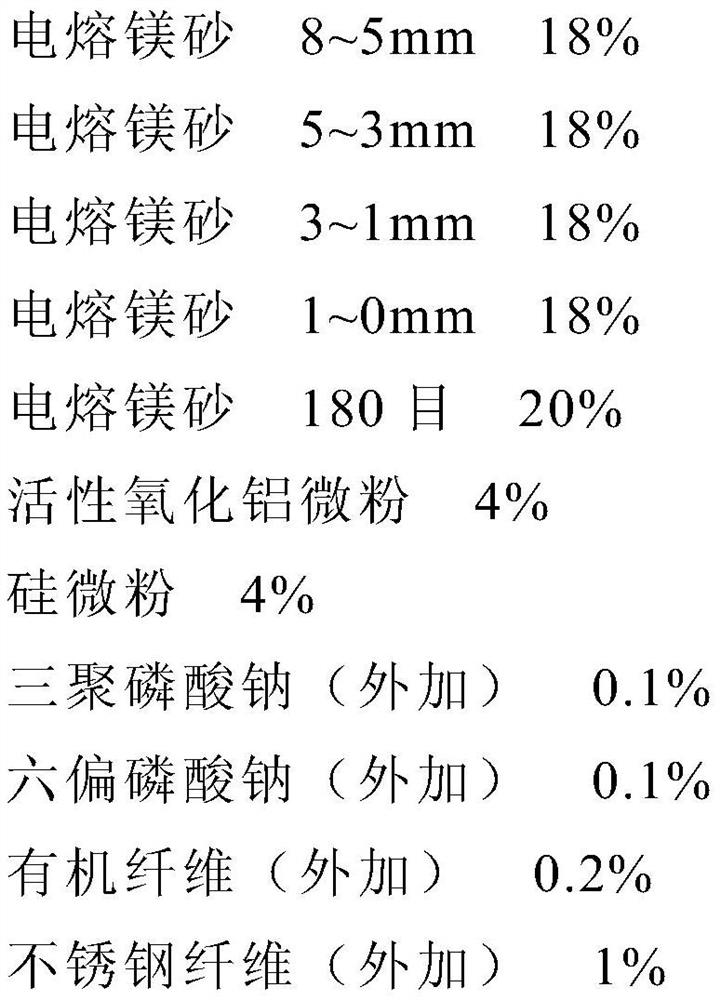

Method used

Image

Examples

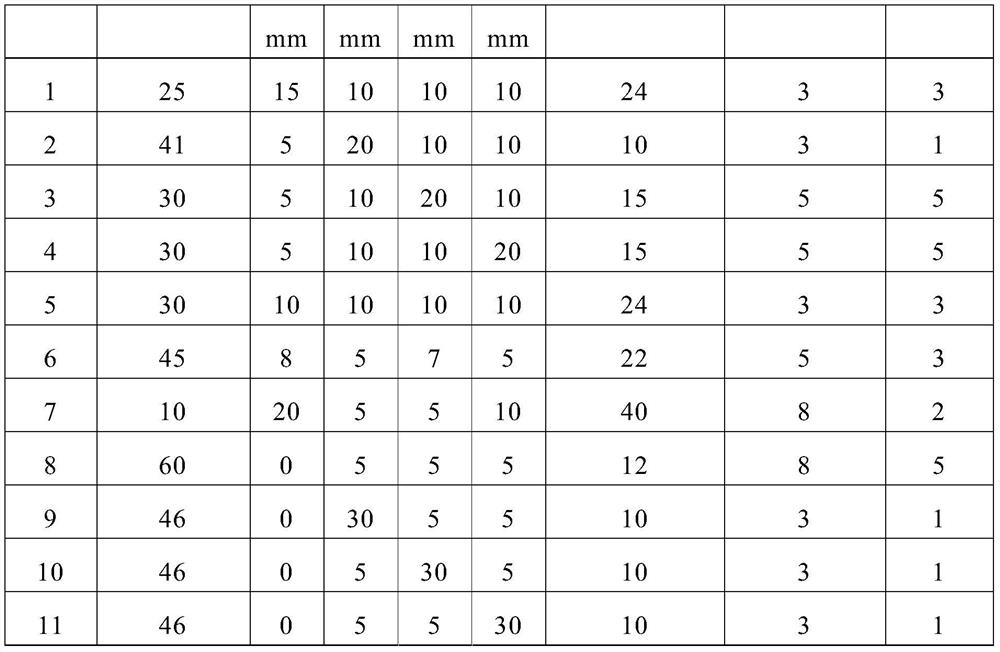

Embodiment 1~11

[0031] A preparation method of a magnesium flow stabilizer for a tundish, comprising the steps:

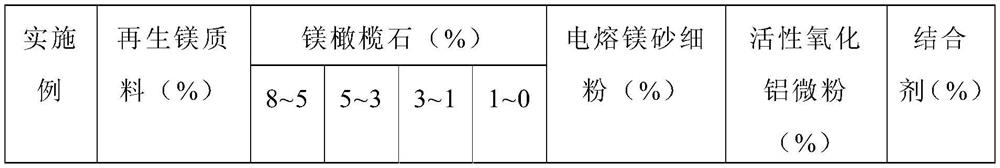

[0032] S1: accurately weigh each component according to the formula of Table 1 and Table 2;

[0033] S2: Mix the components and stir them evenly; the specific mixing sequence is as follows: first, mix the regenerated magnesium raw material and forsterite, and stir them evenly, then add the binder and dispersant and stir them evenly to make a mixture, and then add the mixture to the mixture. Add fused magnesia fine powder, activated alumina micropowder, explosion-proof agent, stainless steel fiber, stir evenly, and finally add water and stir evenly.

[0034] S3: Pouring vibration molding in the mold;

[0035] S4: Conditioning with mold: Combined with Table 3, the mold is cured at 20-50°C for 10-12 hours and then demolded;

[0036] S5: Drying: Combining with Table 3, after demoulding, without natural curing, immediately enter the electric drying kiln to dry, the maximum drying tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com