Method for removing hydrogen sulfide from thickened oil

A technology for hydrogen sulfide and heavy oil, which is used in chemical dehydration/demulsification, petroleum industry, treatment of hydrocarbon oil, etc. It can solve the problems of polluting the environment, poor fluidity, and high viscosity of heavy oil, and achieves convenient use of the process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0055] Embodiment 2, a heavy oil hydrogen sulfide removal device mentioned in the present invention, differs from Embodiment 1 in that: a plurality of support rods 8.7 are designed to fix the colloid filter 8.8, specifically:

[0056] The sediment filter 8 of the present invention includes a sedimentator main body 8.1, a sedimentator sealing cover 8.2, a connecting screw 8.3, an inlet flange 8.4, an outlet flange 8.5, a support column 8.6, a support rod 8.7, a colloid filter 8.8, and a fluid orientator 8.9 , the upper part of the precipitator main body 8.1 is provided with a precipitator sealing cover 8.2, an inlet flange 8.4 is installed at the front water inlet of the precipitator main body 8.1, and an outlet flange 8.5 is installed at the rear end water outlet, inside the precipitator main body 8.1 The cavity is provided with a sedimentation tank 8.10, and the middle part of the sedimentation tank 8.10 is provided with a support column 8.6. The top of the support column 8.6 ...

Embodiment 3

[0057] Embodiment 3, a kind of heavy oil hydrogen sulfide removal device mentioned in the present invention,

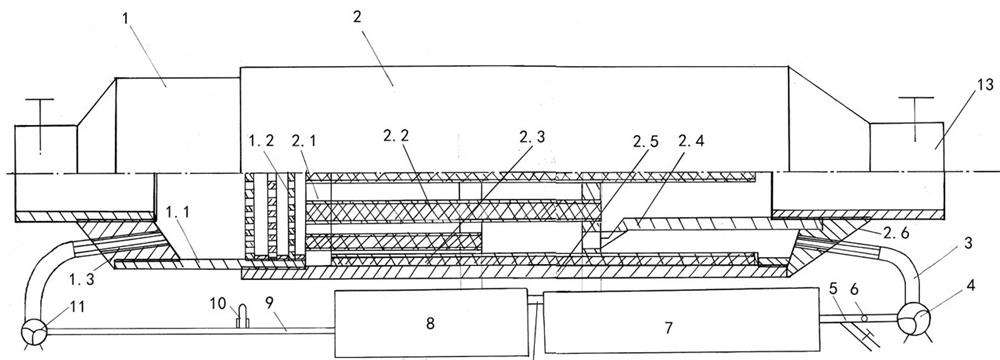

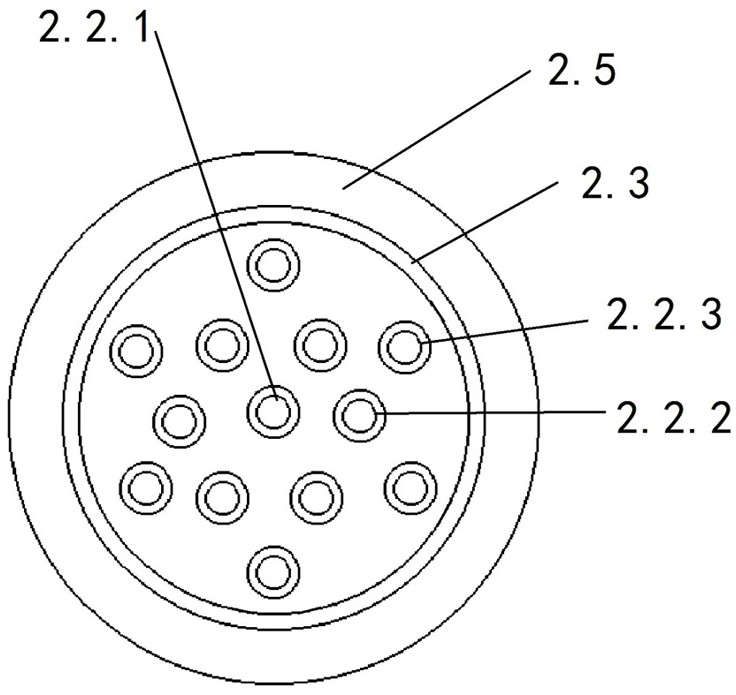

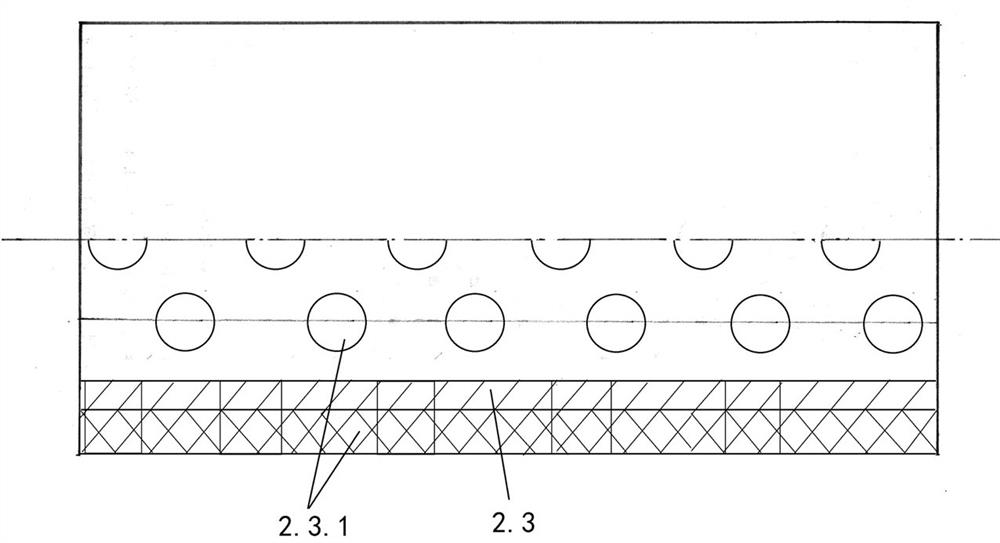

[0058] The emulsifier 1 of the present invention includes an emulsification container 1.1, a multi-stage emulsification plate 1.2, and an emulsifier interface 1.3. One end of the emulsification container 1.1 is a conical structure, and the other end is a cylindrical structure, and one end of the cylindrical structure is provided with The multi-stage emulsification plate 1.2 is provided with an emulsifier interface 1.3 at one end of the conical structure, and the multi-stage emulsification plate 1.2 adopts a multi-stage circular emulsification plate, and a plurality of stages are densely distributed on each stage of the circular emulsification plate. liquid holes, and the apertures of the densely distributed liquid holes on each stage of the circular emulsification plate decrease in turn; the difference from Example 1 is that the liquid flow holes designed on the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com