Automatic electroplating device

An electroplating device and electroplating pool technology, which is applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problems of low degree of automation, easy to affect the natural environment, easy to destroy the natural environment, etc., achieve a high degree of automation, improve the quality of electroplating, and improve Effect of Plating Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

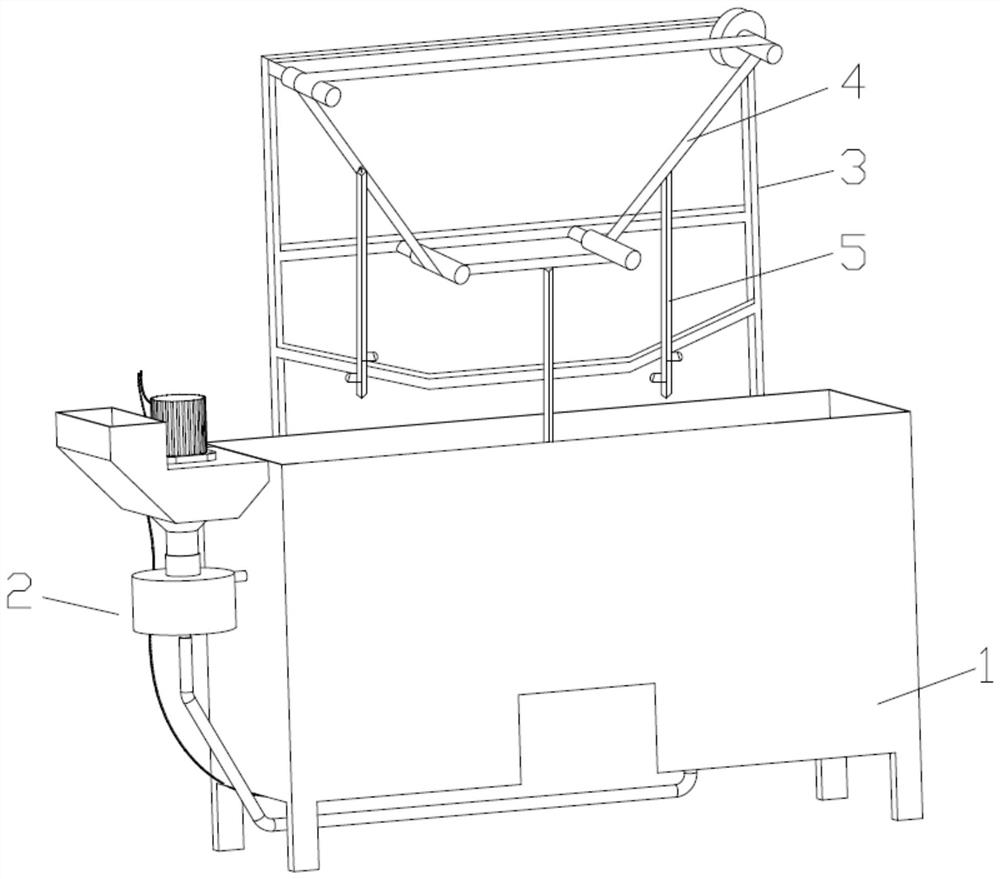

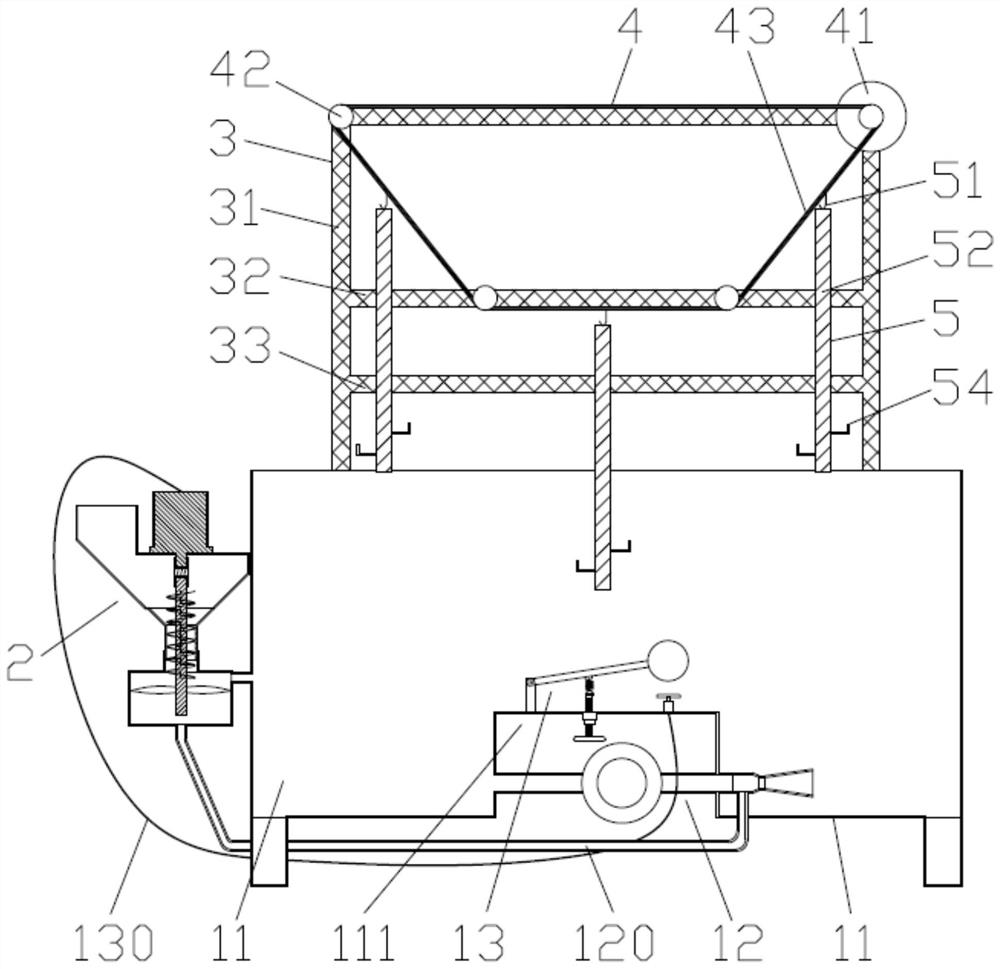

[0044] Such as Figure 1-9 As shown, an automatic electroplating device is characterized in that: it includes an electroplating tank 1, a dosing device 2, an electroplating bracket 3, a transmission device 4, and an electroplating hanger 5; the electroplating bracket 3 is fixedly installed above the side wall of the electroplating pool 1, The transmission equipment 4 is installed on the side of the electroplating bracket 3 close to the electroplating pool 1, and the electroplating rack 5 is installed on the transmission equipment 4, and the electroplating rack 5 is controlled to move toward or away from the electroplating pool 1 through the transmission equipment 4, and the dosing device 2. Set on the other side of the electroplating pool 1 (that is, the side different from the electroplating support), and communicate with this side of the electroplating pool 1;

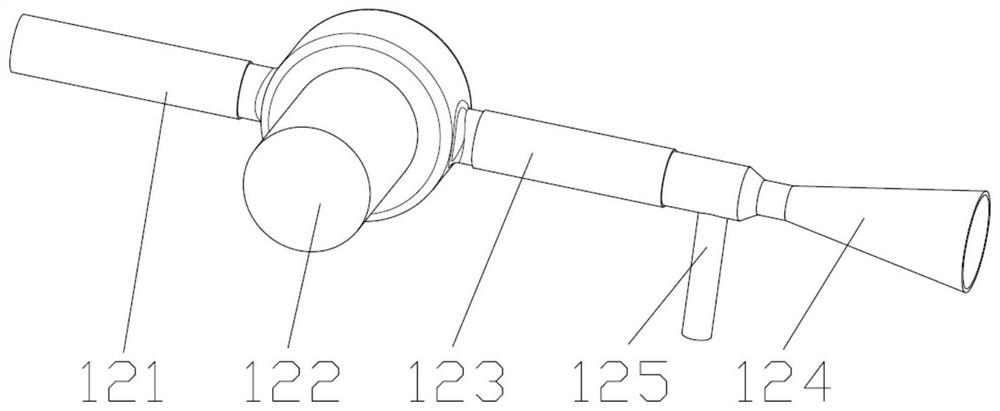

[0045] Electroplating pool 1 comprises electroplating pool body 11, circulation device 12 and sensing device 13; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com