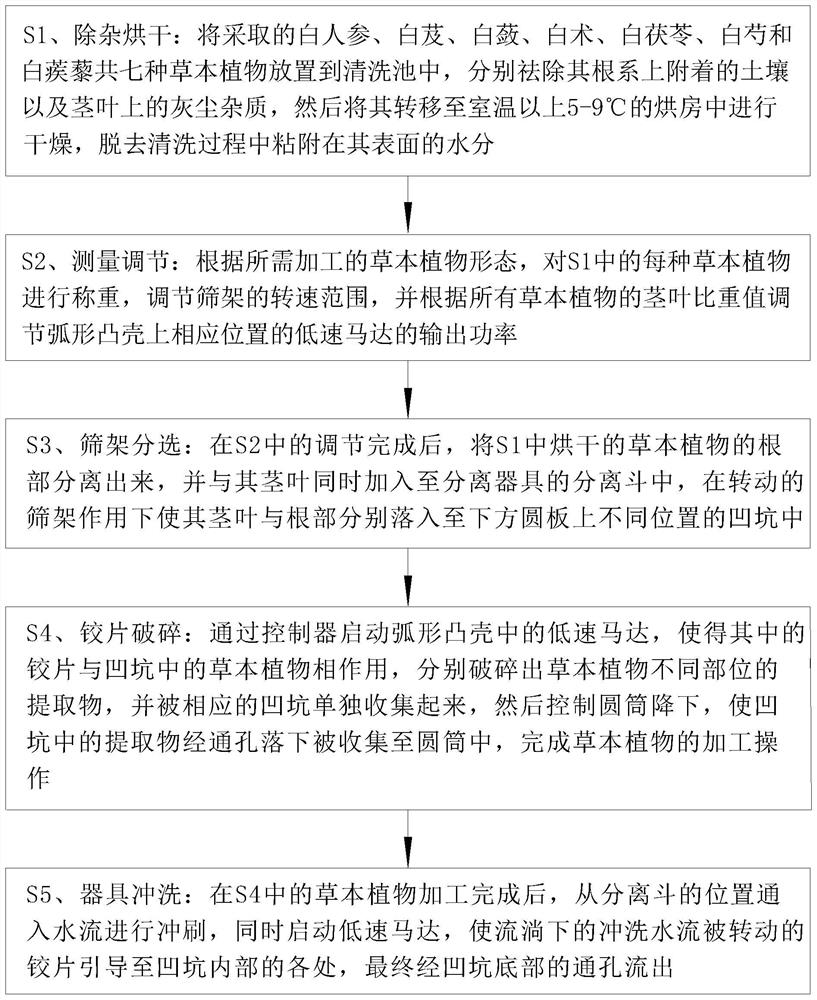

Processing method of whitening herbaceous plants

A technology for herbs and a processing method, applied to the processing field of whitening herbs, can solve the problems of affecting processing quality, difficult to effectively separate stems and leaves, insufficient separation and screening effect of roots, stems and leaves, etc., so as to enhance processing effect, improve washing effect, avoid mixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

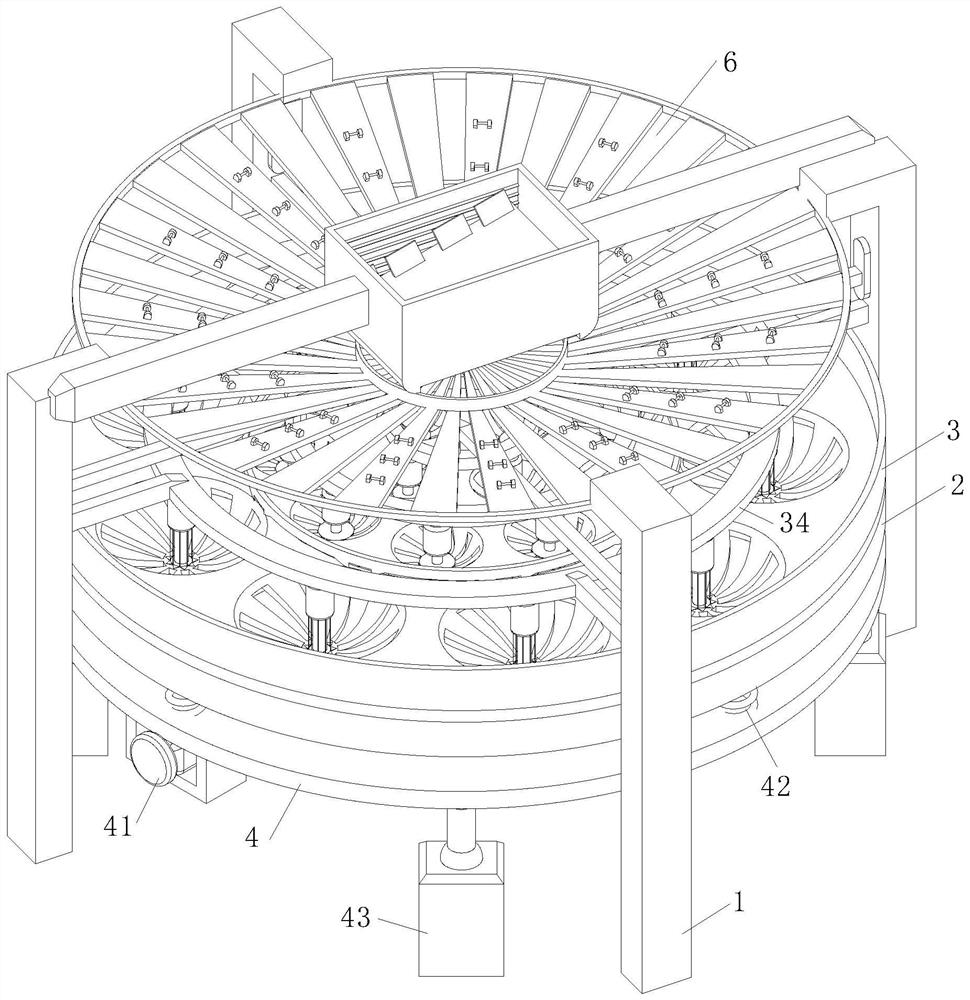

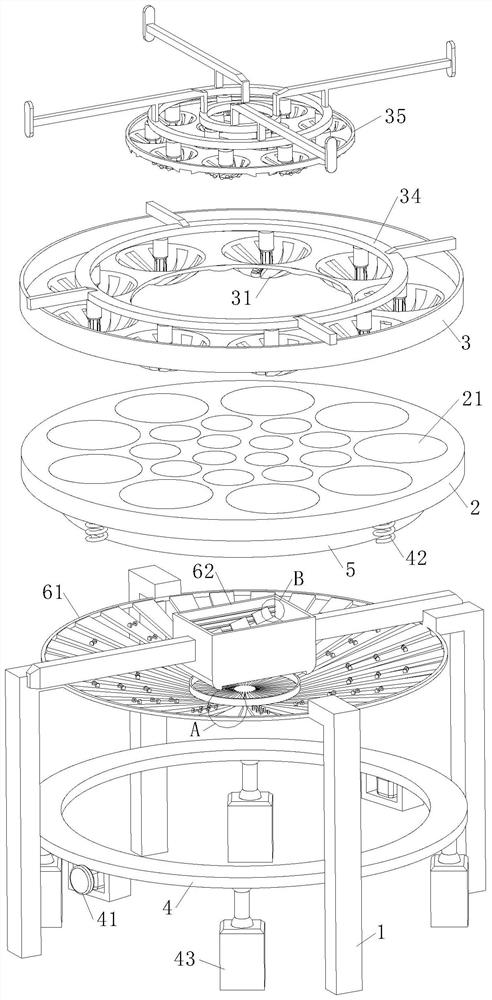

Examples

Embodiment approach

[0047]As an embodiment of the present invention, in the crushing process of the hinge 32, the herbaceous plant powder will adhere to the inner wall of the pit 21 under the action of the plant fluid produced between its tissues. At this time, the control transmission ring 4 The operating power of the vibrating motor 41 on the top, changes the range of vibration frequencies it produces, and adjusts the lifting platform 43 below the transmission ring 4 to be in different rising states, so that the pit 21 in the circular plate 2 is inclined to the horizontal plane; During the adjustment process, the controller changes the rising and falling heights of the adjacent lifting platforms 43 sequentially, so that the inclined surface of the circular plate 2 is in a periodic change, and the height position of the vibration motor 41 under the transmission ring 4 is in the circular position. When the lowest point of the plate 2 inclination changes, its vibration frequency is at the minimum v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com