A dressing material for knee joint inflammation

A knee joint and inflammation technology, which is applied in the field of dressing materials for knee joint inflammation, can solve problems such as weak sticking, not lasting, and no auxiliary effect of drug treatment, so as to improve the comfort of use, ensure breathability, and meet the needs of patients. The effect of high-end demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

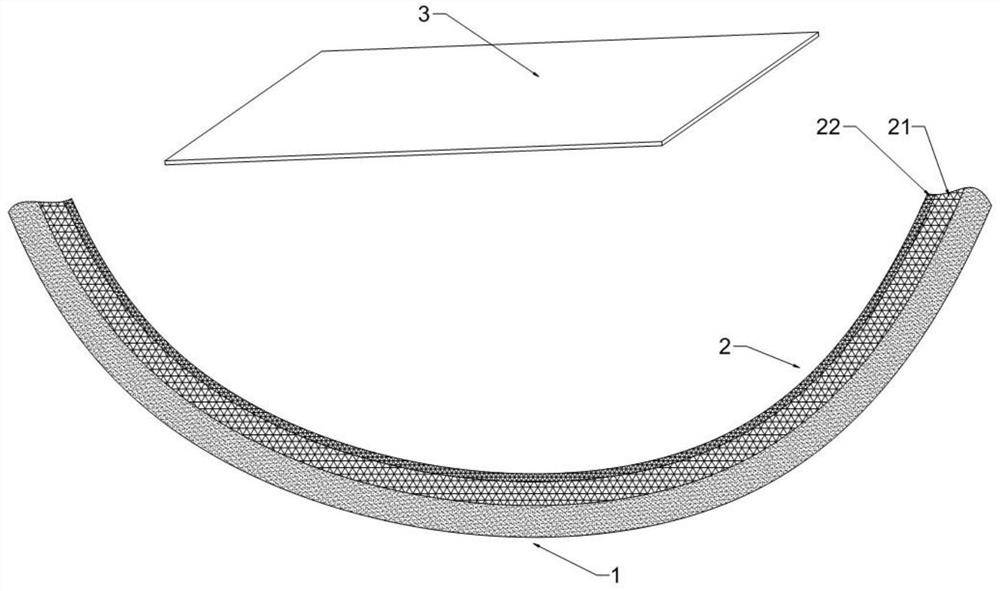

[0027] figure 1 It is a schematic diagram of the structure of the dressing material for knee joint inflammation of the present invention. As shown in the figure, the dressing material includes a bionic support part 1 and a functional lining 2, and is used in conjunction with a drug patch 3. The bionic support part 1 is The solid shell material 3D printed according to the human knee joint data model, the functional lining 2 is a flexible lining material with a certain thickness 3D printed inside the bionic support part 1, the flexible lining The material is a flexible grid structure or a flexible braided structure, and the drug patch 3 is laid on the inner side of the functional liner 2 for attachment to the knee joint of a human body.

[0028] The method for preparing the above-mentioned dressing material by 3D printing includes:

[0029] Step S1: Use a 3D scanner to collect the user's knee information to obtain knee features; when collecting the user's knee information in th...

Embodiment 2

[0041] This embodiment is a further example of the 3D printing process used to print the bionic support part 1 and the functional lining 2. As mentioned above, in addition to fused deposition modeling, laser selective melting and photocuring molding are also preferred solutions. Specifically, Selective laser melting and photo-curing molding have more accurate profiling accuracy when manufacturing the bionic support part 1, and also have a higher success rate than fused deposition molding when preparing a grid structure with a certain design shape (not a simple weaving structure). Therefore, this embodiment adopts laser selective melting or photocuring molding to implement manufacturing. In specific manufacturing, laser selective melting or photocuring molding can be directly used to complete the preparation of the entire covering material, and laser selective melting or photocuring molding A grid with a lattice structure is produced by means of a method as the structure of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com