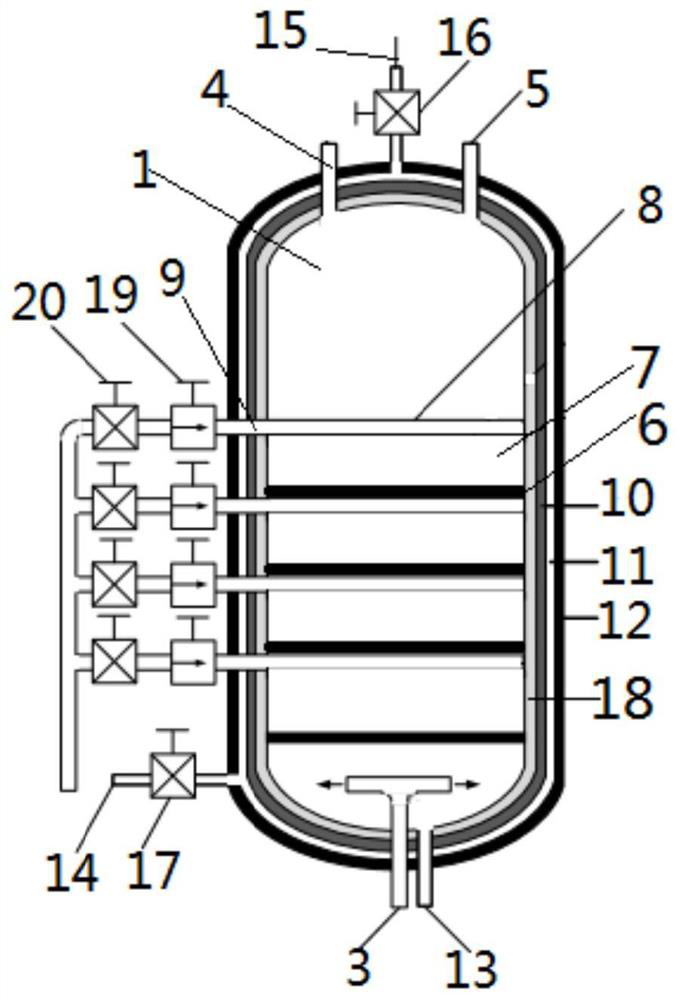

Hydration reaction device

A hydration reaction and reactor technology, applied in the chemical method of reacting liquid and gas medium, chemical/physical/physicochemical fixed reactor, gas fuel, etc., can solve the problem of low separation rate and difficult control of reaction temperature, etc. problems, to achieve the effect of increasing the reaction rate and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

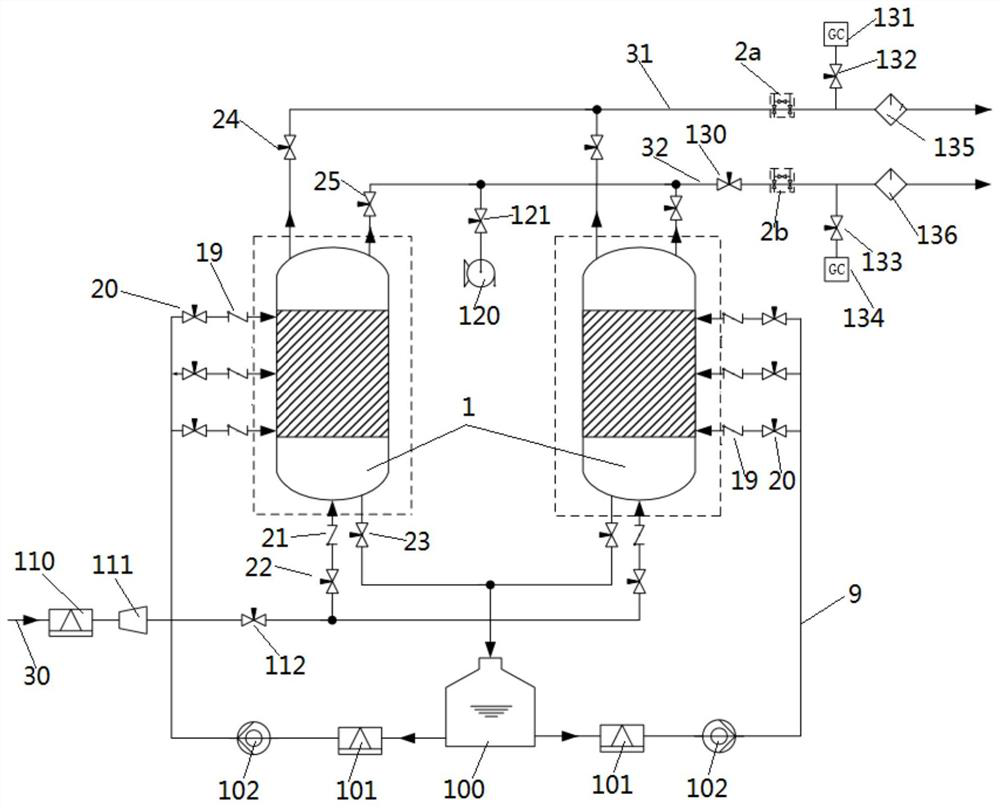

Method used

Image

Examples

specific Embodiment approach

[0060] The composition of CBM is 72.5% CH 4 , 24% N 2 and 3.5% O 2 , the generating liquid is an aqueous solution with 0.05wt% sodium dodecyl sulfate added, and the porous media filler 7 is coarse-porous silica gel. The cooling liquid outlet valve 16 and the cooling liquid inlet valve 17 of the two reactors were opened to circulate the cooling medium with a temperature of 1° C. in the temperature control channel 11 . Set the temperature of the liquid coolers 101 of the two reactors at 1°C, open the replenishment needle valves 20 of the two reactors, and the generated liquid in the liquid storage tank 100 passes through the liquid coolers 101 on the two reactors, the hydraulic pressure The pump 102 , the liquid replenishment needle valve 20 and the liquid replenishment one-way valve 19 respectively flow out from the liquid replenisher 8 of the two reactors and contact with the porous medium packing 7 . In addition to injecting liquid through the liquid replenishment pipe 9 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com