Phase alignment manufacturing tool clamp for internal and external teeth of precision gear and manufacturing method

A technology for manufacturing tooling and internal and external teeth, which is applied in the manufacturing field of precision gears, internal and external teeth, fixtures and manufacturing fields. It can solve the problems of planetary gear tooth orientation errors, increased difficulty of planetary gears on eccentric shafts, and inconsistency between internal and external gear orientations of planetary gears. Achieve high yield, strong phase consistency of internal and external teeth, and eliminate processing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

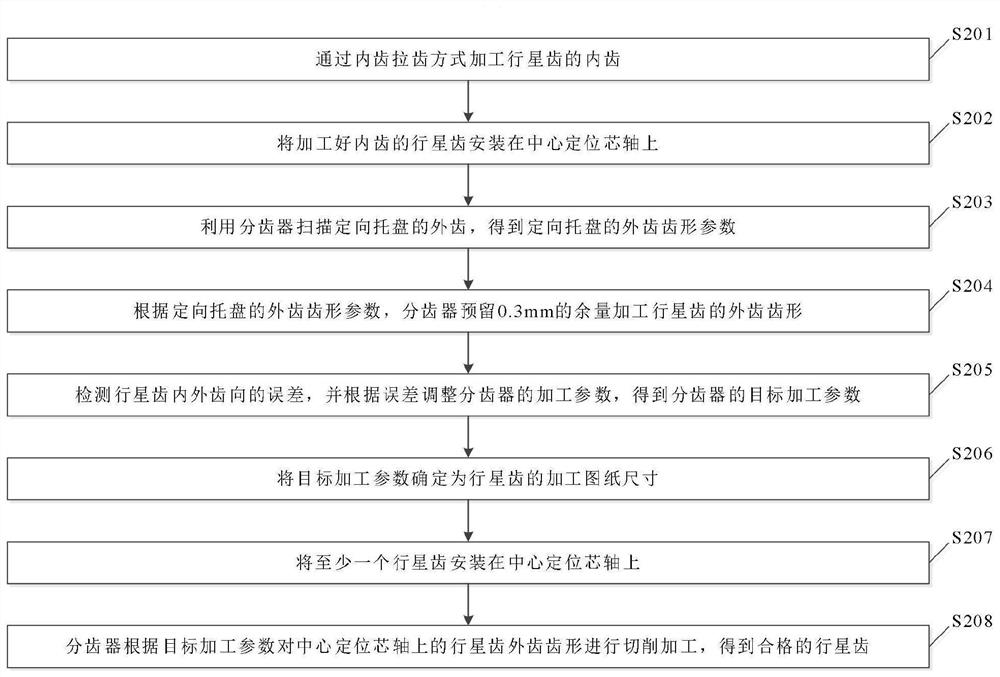

[0024] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

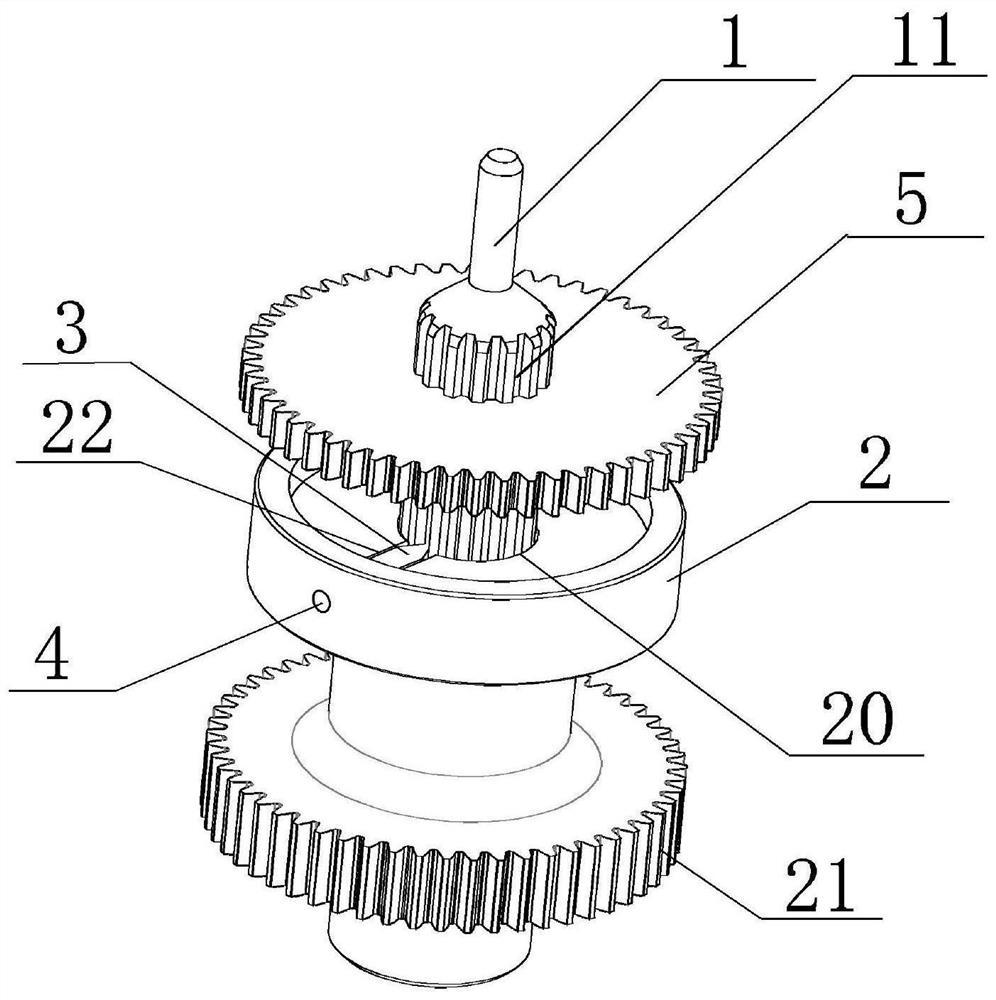

[0025] see figure 1 , figure 1 It is a structural schematic diagram of a precision gear internal and external tooth pair phase manufacturing jig of the present invention.

[0026] A tooling fixture for manufacturing precision gear internal and external tooth pairs, including a center positioning mandrel 1 and an orientation tray 2, the outer surface of the center positioning mandrel 1 is provided with tooth grooves 11, and the orientation tray 2 is pierced through a center hole 20 set in the center On the centering mandrel 1, and the phase of the external teeth 21 of the orientation tray 2 is the same as the phase of the tooth groove 11 of the centering mandrel 1, the planetary gear 5 is clamped on the centering mandrel 1 for processing the planetary gear profile.

[0027] In this embodiment, the design that the phase of the outer teeth of the direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com