Automatic welding equipment for vehicle-mounted fuel tank production

An automatic welding and fuel tank technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as low work efficiency, difficult welding methods, low welding strength and welding quality, and achieve convenient protection and improved practicability and reliability, and the effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

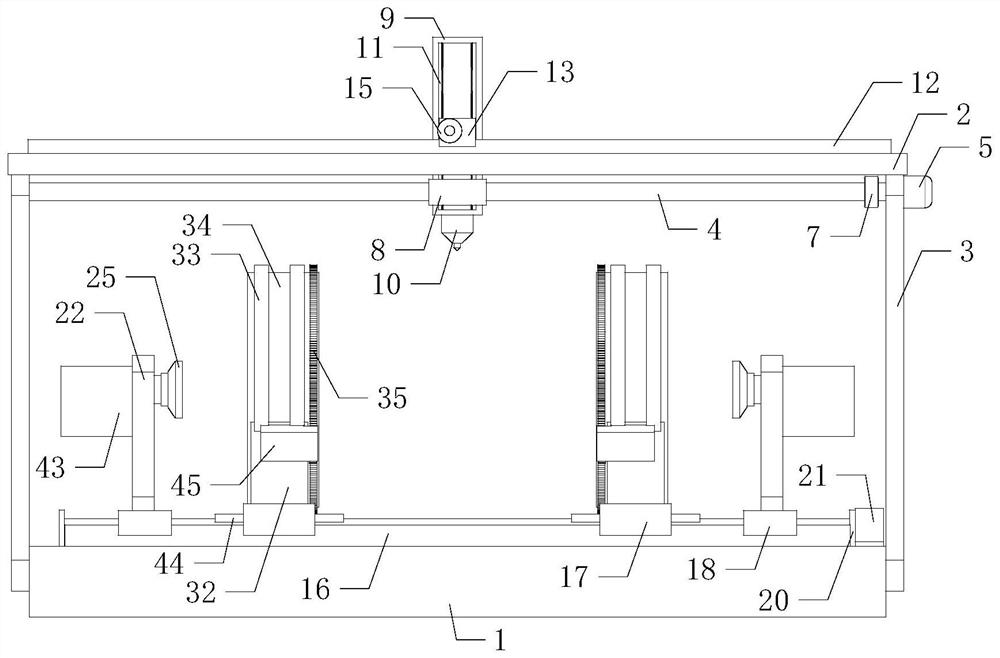

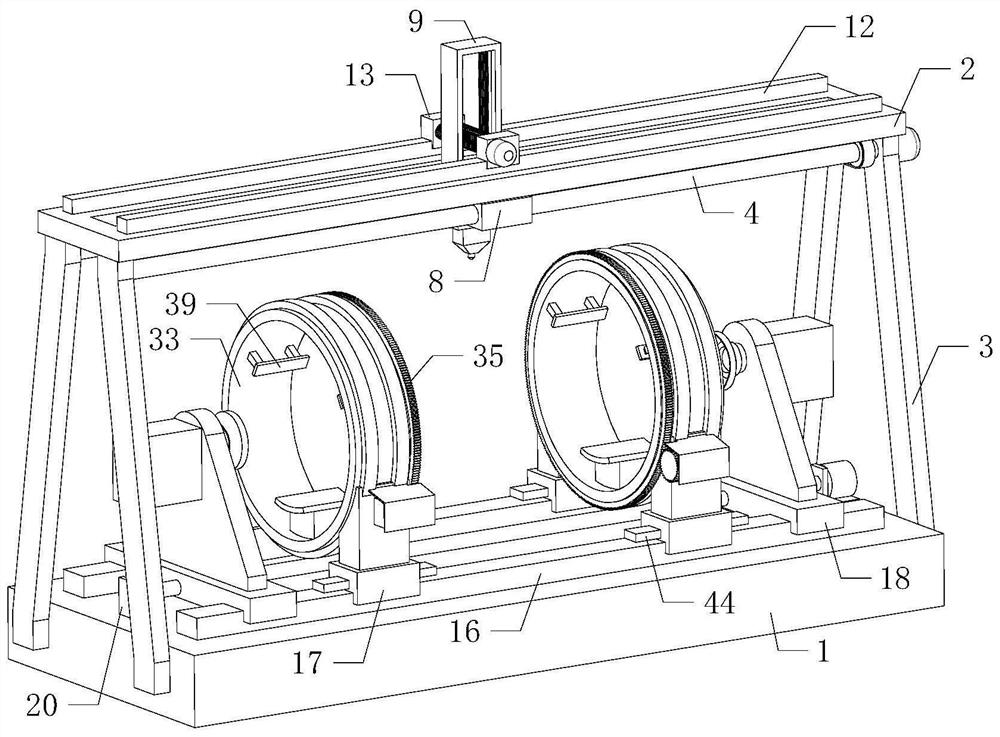

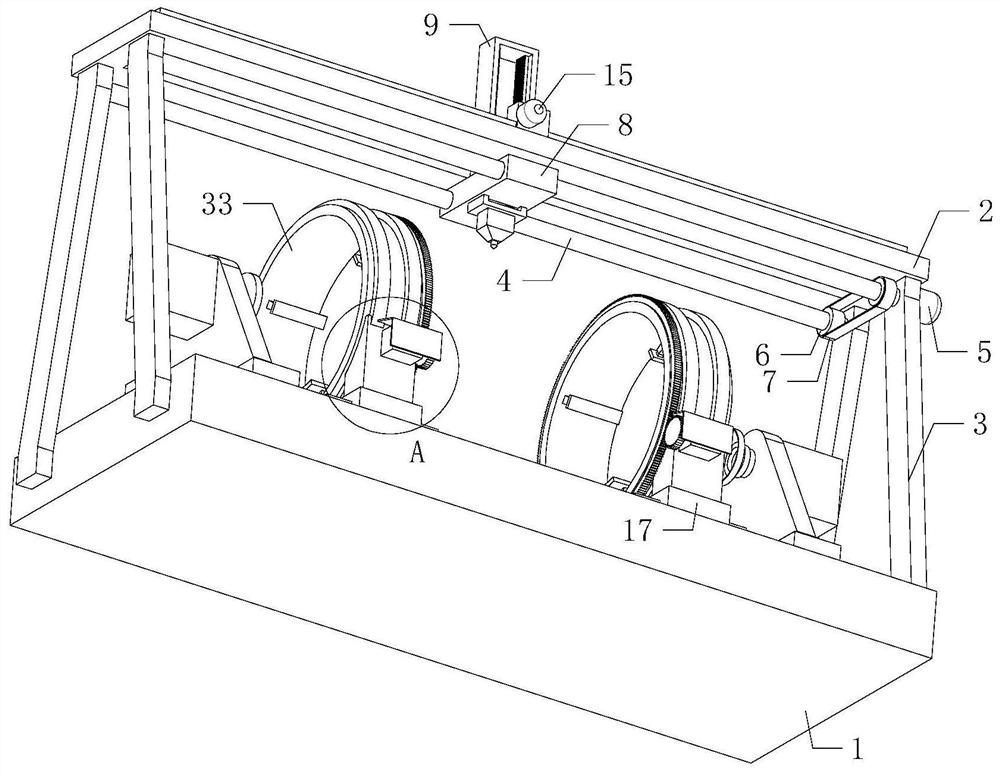

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0022] Such as Figure 1 to Figure 7 As shown, the automatic welding equipment for the production of a vehicle-mounted fuel tank of the present invention fixes the external fuel tank originals to be spliced and welded on two sets of fixing devices when it is working, the docking positions of the two sets of originals are opposite, and the power unit Control the two groups of adsorption devices to approach each other, the inner sides of the two groups of adsorption devices are respectively in contact with the outer walls of the two groups of originals, open the two groups of adsorption devices, and the two groups of adsorption devices respectively carry out adsorption and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com