Zero-discharge treatment system and process for MBT-containing industrial wastewater

A technology for industrial wastewater and treatment systems, applied in water/sewage treatment, heating water/sewage treatment, neutralized water/sewage treatment, etc., can solve problems such as complex wastewater composition, damage to purification equipment and pipelines, and reduced purification treatment effect , to achieve great economic significance and environmental protection benefits, reduce recycling costs, and reduce solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] MBT-containing wastewater sample 1, the initial pH value is 8.45, COD Cr It is 22600mg / L.

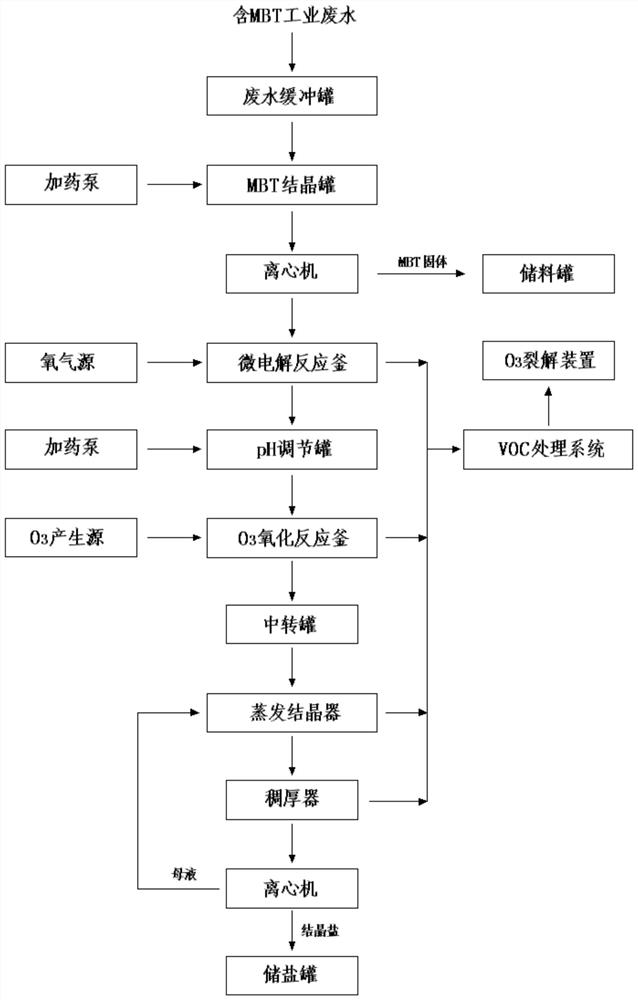

[0058] The zero-discharge treatment system containing MBT industrial wastewater described in the present embodiment 1 includes an MBT recovery system, an oxidation decomposition system, an evaporative desalination system and a tail gas purification system; the MBT recovery system includes a wastewater buffer tank and an MBT crystallization tank and recovery device; the oxidative decomposition system includes micro-electrolysis reactor, pH adjustment tank and O 3 Oxidation reactor; the evaporation and desalination system includes a transfer tank, evaporation crystallizer, thickener and salt extraction pump; the recovery device in the MBT recovery system is connected with the micro-electrolysis reactor in the oxidation decomposition system, O in the oxidative decomposition system 3 The water outlet of the oxidation reaction kettle is connected with the water inlet of the transfer...

Embodiment 2

[0077] Containing MBT wastewater sample 2, the initial pH value is 9.23, COD Cr It is 52600mg / L.

[0078] The zero-discharge treatment system containing MBT industrial wastewater described in Example 2 is the same as Example 1.

[0079] The zero-discharge treatment process containing MBT industrial waste water described in the present embodiment 2 consists of the following steps:

[0080] After the water sample is filtered by the grid, it enters the waste water buffer tank; the water sample in the waste water buffer tank is transported to the MBT crystallization tank and the stirring device of the MBT crystallization tank is turned on, and 98% concentrated sulfuric acid is added to the water sample to adjust the pH value to 3.06; after stirring for 50 minutes, the suspension of the mixed MBT solid was sent to the centrifugal pump, and the MBT solid obtained after centrifugation by the centrifugal pump was collected into the storage tank; the centrifuged liquid was sent to the...

Embodiment 3

[0083] MBT containing wastewater sample 3, the initial pH value is 8.14, COD CrIt is 32400mg / L.

[0084] The zero-discharge treatment system containing MBT industrial wastewater described in Example 3 is the same as Example 1.

[0085] The zero-discharge treatment process containing MBT industrial wastewater described in the present embodiment 3 consists of the following steps:

[0086] After the water sample is filtered by the grid, it enters the waste water buffer tank; the water sample in the waste water buffer tank is transported to the MBT crystallization tank and the stirring device of the MBT crystallization tank is turned on, and 30% sulfuric acid is added to the water sample to adjust the pH value to 3.56; after stirring for 30 minutes, transport the suspension of the mixed MBT solid to the centrifugal pump, and the MBT solid obtained after centrifugation by the centrifugal pump is collected into the storage tank; the liquid after centrifugation is transported to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com