Multi-element solid waste concrete block and preparation method thereof

A technology of waste concrete and blocks, which is applied in the field of building materials, can solve the problems of single construction waste disposal method and resource utilization rate of less than 10%, and achieve the effects of improving defects, promoting resource utilization, and improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

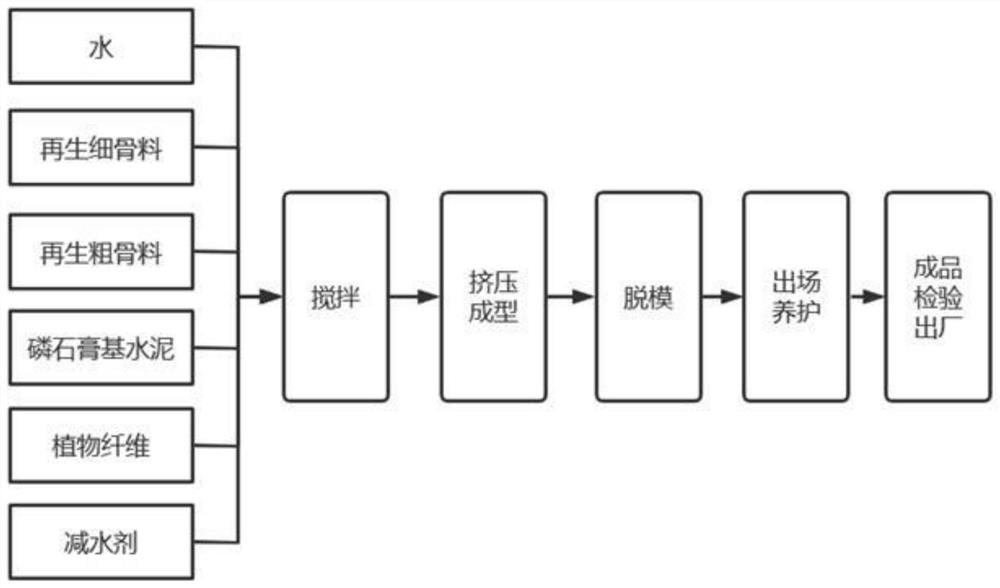

Image

Examples

Embodiment 1

[0036] Preparation of recycled coarse aggregate: Recycled coarse aggregate with a particle size of 4.75mm-31.5mm is obtained by removing debris, crushing and screening construction waste.

[0037] Preparation of recycled fine aggregate: Recycled fine aggregate with a particle size of less than 4.75mm is prepared by removing debris, crushing and screening construction waste.

[0038] Fiber preparation: The straw is processed by dust removal, cutting, etc. to make plant fibers with a fiber length of 0.1 to 3.0 mm.

[0039] Preparation of phosphogypsum-based cement: phosphogypsum-based cement is prepared according to the mass percentage of each component material, phosphogypsum is 45, slag is 45, steel slag is 2, limestone is 4, and Portland cement clinker is 4. The Portland cement clinker is P.O52.5 grade.

[0040] Making multi-component solid waste concrete blocks: After the raw materials are prepared, the automatic batching system automatically batches phosphogypsum-based cem...

Embodiment 2

[0042] Preparation of recycled coarse aggregate: Recycled coarse aggregate with a particle size of 4.75mm-31.5mm is obtained by removing debris, crushing and screening construction waste.

[0043] Preparation of recycled fine aggregate: Recycled fine aggregate with a particle size of less than 4.75mm is prepared by removing debris, crushing and screening construction waste.

[0044] Fiber preparation: The wheat straw is processed by dust removal, cutting, etc. to make plant fibers with a fiber length of 0.1-3.0 mm.

[0045] Preparation of phosphogypsum-based cement: phosphogypsum-based cement is prepared according to the mass percentage of each component material, phosphogypsum is 45, slag is 45, steel slag is 2, limestone is 4, and Portland cement clinker is 4. The Portland cement clinker is P.O52.5 grade.

[0046]Making multi-component solid waste concrete blocks: After the raw materials are prepared, the automatic batching system automatically batches phosphogypsum-based c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap