Method for preparing high-molecular polymer through anionic polymerization of alkyl acrylate polar monomers

A technology of alkyl acrylate and high molecular polymers, applied in the field of high molecular polymers, can solve the problems of difficult acquisition of side reaction inhibitors, insufficient industrial application value, increase of preparation steps, etc., to achieve the benefits of industrial production operations, The effect of overcoming potential difficulties and simple reaction system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

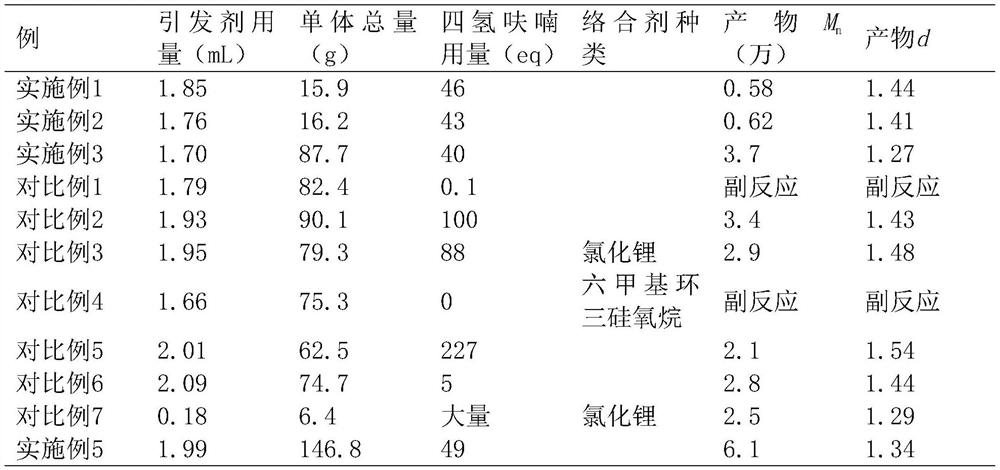

[0034] Example 1: Methyl methacrylate homopolymer.

[0035] Under the temperature condition of 25°C, 1241g of toluene and 2.0g of 1,1-stilbene were added to the reactor. Add 1.85 mL of n-butyllithium hexane solution to initiate reaction for 1 h. Cool down to 12°C, add 7.8g tetrahydrofuran (46eq), and react for 1h. Add 13.9g of methyl methacrylate and react for 1h. After the reaction was completed, isopropanol was added to terminate the reaction. The product was precipitated with ethanol and washed, and dried under vacuum at 40°C for 12h. Analyze product with gel permeation chromatography (GPC), its number average molecular weight M n =5.8×10 3 , Molecular weight distribution width (polydispersity coefficient) d=1.44.

Embodiment 2

[0036] Embodiment 2: methyl methacrylate-n-butyl acrylate copolymer.

[0037] Under the temperature condition of 21°C, 1089g of toluene and 1.8g of 1,1-stilbene were added to the reactor. Add 1.76 mL of n-butyllithium hexane solution to initiate reaction for 1 h. Cool down to 8°C, add 7.2g tetrahydrofuran (43eq), and react for 1h. Add 9.0 g of methyl methacrylate and 5.4 g of n-butyl acrylate, and react for 1 h. After the reaction was completed, isopropanol was added to terminate the reaction. The product was precipitated with ethanol and washed, and dried under vacuum at 40°C for 12h. The product was analyzed by GPC, its M n =6.2×10 3 , d=1.41.

Embodiment 3

[0038] Example 3: Styrene-methyl methacrylate copolymer.

[0039] Under the temperature condition of 24°C, 1003g of toluene and 66.3g of styrene were added to the reactor. Add 1.70 mL of n-butyllithium hexane solution to initiate reaction for 1 h. Add 1.7g 1,1-stilbene and react for 0.5h. Cool down to 6°C, add 6.8g tetrahydrofuran (40eq), and react for 1h. Add 19.7g of methyl methacrylate and react for 1h. After the reaction was completed, isopropanol was added to terminate the reaction. The product was precipitated with ethanol and washed, and dried under vacuum at 40°C for 12h. The product was analyzed by GPC, its M n =3.7×10 4 , d=1.27.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com