Soft-touch HIPS composition and preparation method thereof

A composition and soft-touch technology, which is applied in the field of soft-touch HIPS composition and its preparation, can solve the problems of poor touch on the surface of materials, achieve the effects of reducing hardness, broad market application prospects, and improving impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

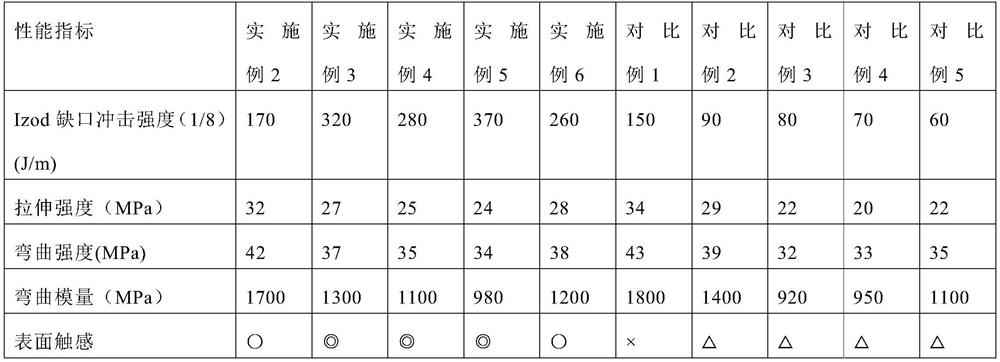

Examples

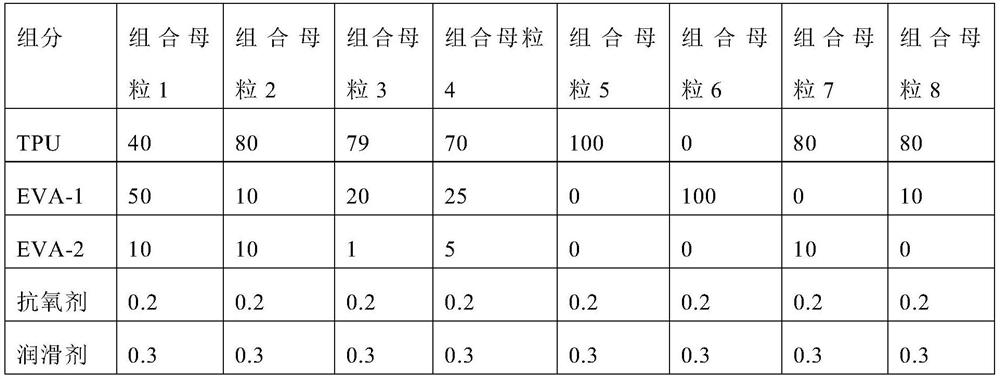

Embodiment 1

[0045] This example is the preparation of tactile-modified masterbatch. The ratio of raw materials is shown in Table 1. The specific preparation method is as follows:

[0046] A1, take each raw material component according to the parts by weight of Table 1;

[0047] B1. Fully stir each component in A1, and mix in a mixer for 20-40 minutes to obtain a mixture;

[0048] C1, the mixture obtained in step B1 is entered from the main feed of the twin-screw extruder and melted and extruded, then cooled, dried, and pelletized to obtain the combined masterbatch;

[0049] Among them, the twin-screw extruder is a twin-screw extruder rotating in the same direction, the length-to-diameter ratio of the screw is 35, and the screw barrel is provided with a vacuum exhaust device and a temperature control device; the temperature of the feed section of the twin-screw extruder is 200°C, the temperature of the plasticizing section is 190°C, the temperature of the homogenization section is 200°C; ...

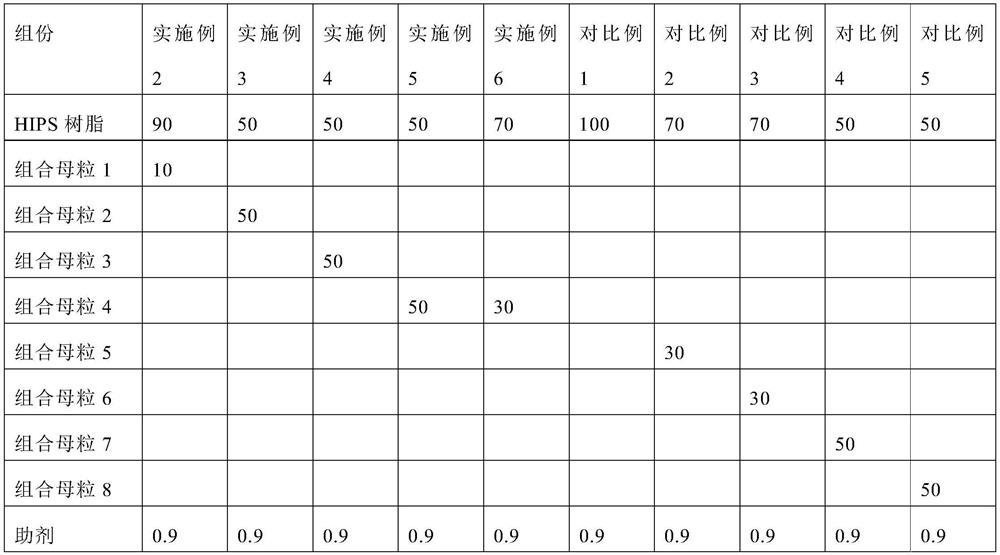

Embodiment 2

[0055] This embodiment provides a soft-touch HIPS composition and a preparation method thereof, and the specific steps are as follows:

[0056] (1) Take each component according to the weight ratio in Table 2, wherein the auxiliary agent is an antioxidant and a lubricant with a weight ratio of 1:1;

[0057] (2) each component that weighs is mixed in high-speed mixer and obtains mixture after 20min;

[0058]The above-mentioned mixed mixture is entered from the main feed of the twin-screw extruder, and the sample is obtained through melt extrusion, cooling, drying, and pelletizing; wherein, the twin-screw extruder is a co-rotating twin-screw extruder, The length-to-diameter ratio of the screw is 40, and the screw barrel is equipped with a vacuum exhaust device and a temperature control device; the temperature of the feed section of the twin-screw extruder is 200°C, the temperature of the plasticizing section is 190°C, and the temperature of the homogenization section is 200°C; ...

Embodiment 3

[0060] This example provides a soft-touch HIPS composition and its preparation method. The weight ratio of raw materials is shown in Table 2, and the preparation method is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com