Automatic lifting and overturning mechanism for refractory material thermal shock test device

A technology of automatic lifting and testing device, applied in the field of refractory materials, can solve the problems of slow speed, laborious, long time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

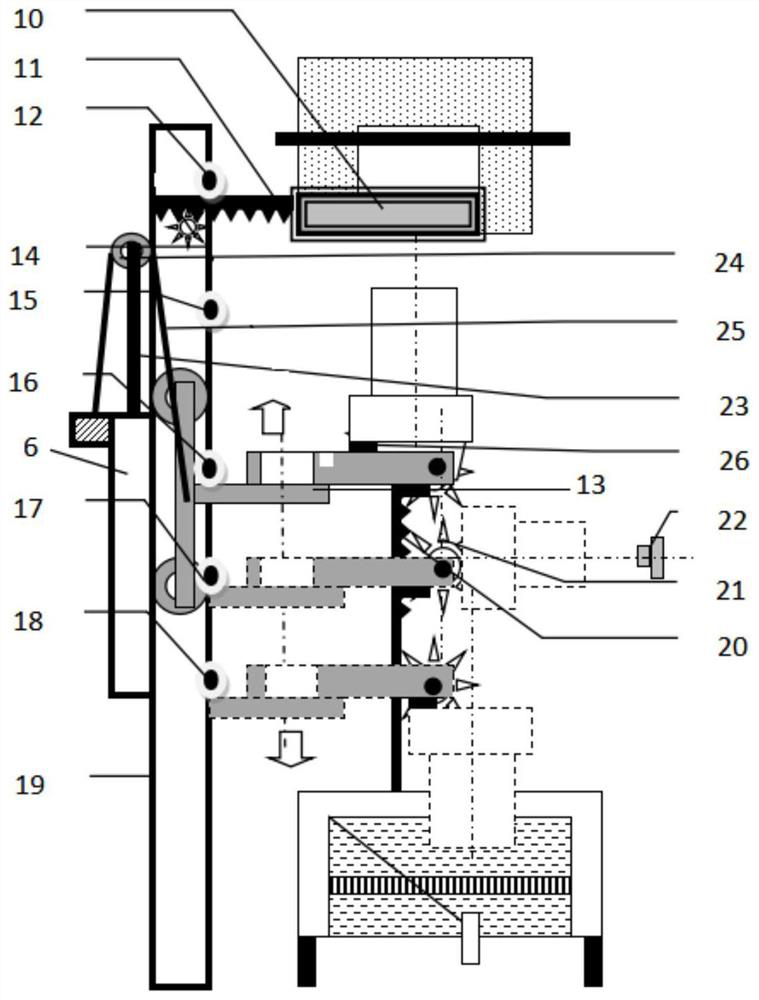

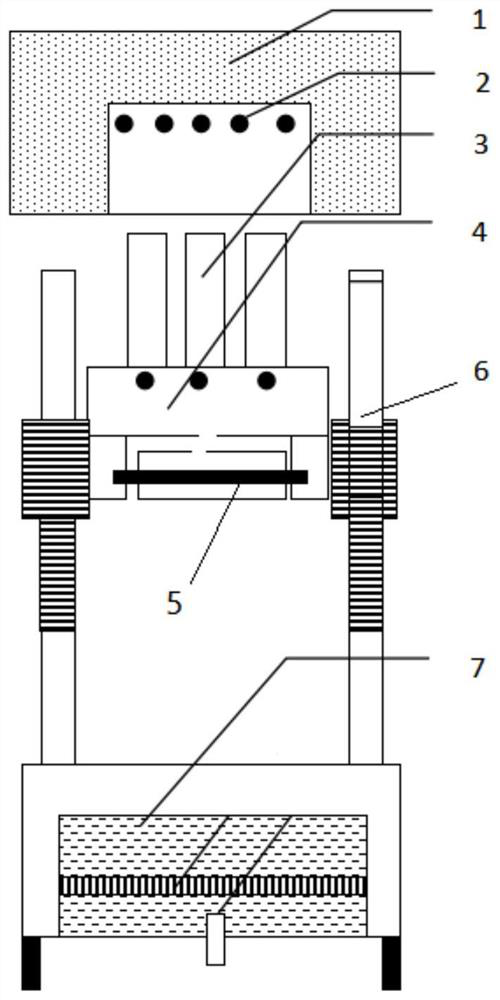

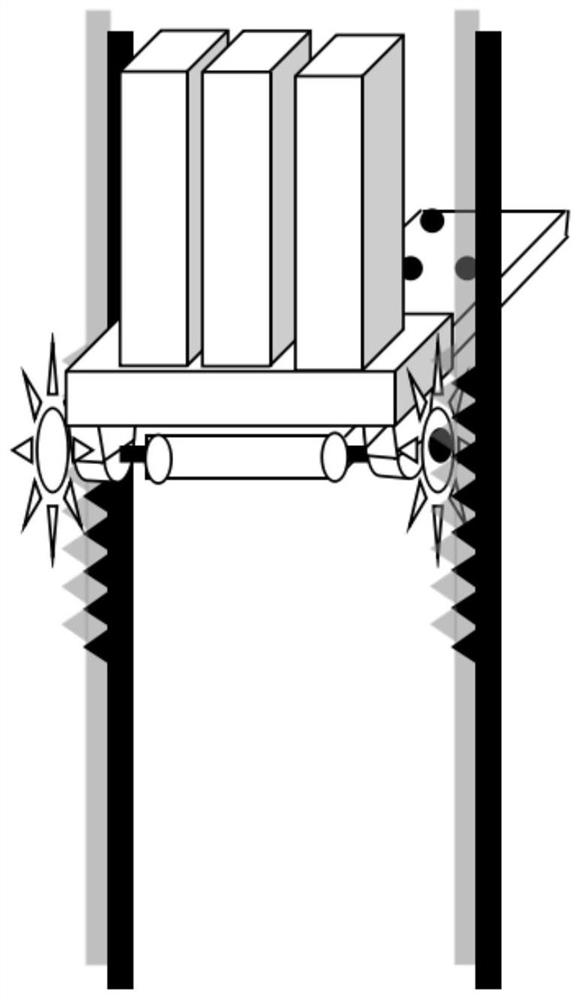

[0017] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0018] See Figure 1-Figure 3 As shown, the automatic lifting and turning mechanism for a thermal shock test device for refractory materials related to the present invention includes an automatic lifting system and an automatic turning system. 25. The controller A15, the positioning controller B16, the positioning controller C17 and the positioning controller D18 are composed, wherein the piston lifter 6 is fixed on the frame 19 outside the heating furnace 1, and it is connected with the movable pulley sprocket 24 through the ejector rod 23, One end of the chain 25 is fixed on the frame 19, and the other end passes through the movable pulley sprocket 24 and is connected with the automatic turning system; the positioning controller A15, the positioning controller B16, the positioning controller C17 and the positioning controller D18 are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com