A modular wellhead foam content detection device

A detection device and modular technology, which is applied to measurement devices, instruments, scientific instruments, etc., can solve the problems that detection accuracy is easily disturbed by human factors, cannot detect the real-time foam content of pipes, wastes human and material resources, etc. The effect of replacement, installation is simple, and operation is convenient and fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

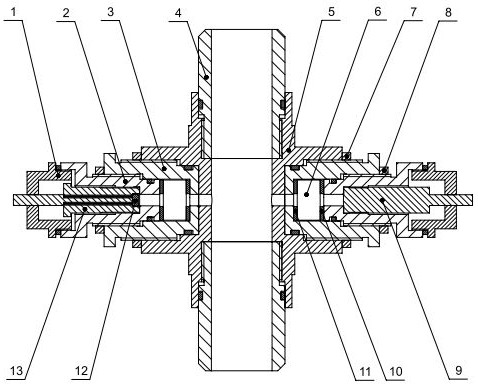

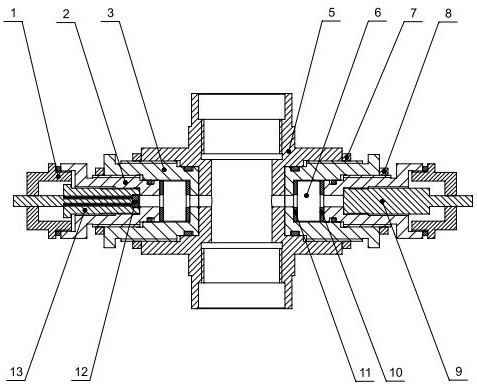

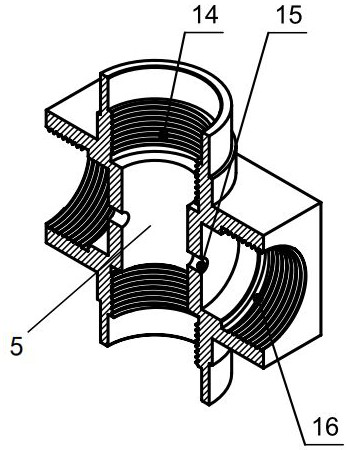

[0028] Such as figure 1 The assembled device shown is the first working condition. It is used in the existing field where pipelines have been installed. The whole device is welded to the field pipeline through the connecting pipeline 4 at both ends. During the gas production process, the pressure in the pipeline is given to When the toughened glass 6 pushes outwards, the inner variable diameter joint 2 squeezes the toughened glass 6 and the inner sealing gasket 11 and the outer sealing gasket 10 at both ends to form an end face seal; the power supply line of the laser transmitter 9 and the linear silicon photoelectric cell 12 The signal line is connected to the power module and signal processing module outside the well site, the laser transmitter 9 is turned on to emit laser light, and the first through hole 15, the second through hole 18 and the third through hole 19 are in a line, so that the laser light passes through , the linear silicon photocell 12 receives the laser to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com