Regulation and control method of meat source composite enzyme system and application thereof

A technology of compound enzyme system and meat source is applied in the field of regulation of meat source compound enzyme system, which can solve the problems of inability to precisely regulate enzyme activity and high cost, and achieve improved flavor and quality, good maturity and flavor quality, and controllability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

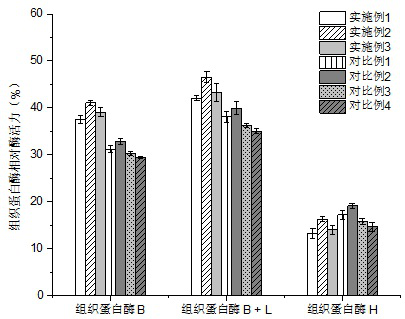

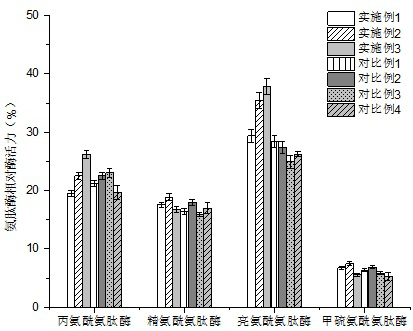

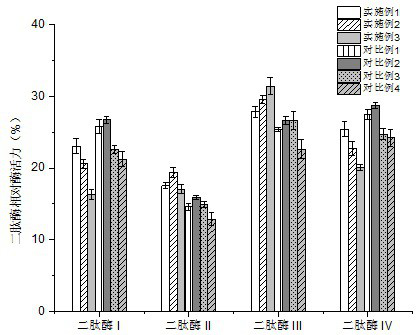

Examples

Embodiment 1

[0031] This embodiment uses a method for regulating and controlling the meat-derived compound enzyme system, and the specific operations are as follows:

[0032] (1) Picking salt is composed of sodium chloride, potassium chloride, calcium chloride, magnesium chloride and zinc chloride, the ratio of which is 34.8:2.6:1.3:1.3:0.3 (molar ratio);

[0033] (2) Curing the raw meat with the salt for curing, the ratio of the meat and the salt for curing is 100:3;

[0034] (3) The low temperature control technology includes the following process:

[0035] In the salting stage, the temperature is controlled at 3-4°C, and the relative humidity is 80-85%, for 2 days;

[0036] Pickling equilibrium stage, temperature is 4-5°C, relative humidity is 75-80%, 7 days;

[0037] In the air-drying stage, the temperature is 5-20°C, the relative humidity is 65-75%, 30 days;

[0038] In the mature stage, the temperature is 18-20°C, the relative humidity is 70-80%, 80 days;

[0039] (4) Take a matu...

Embodiment 2

[0041] This embodiment uses a meat-derived complex enzyme regulation method, using the same method as in Example 1, the difference is that sodium chloride, potassium chloride, calcium chloride, magnesium chloride, and zinc chloride are used in pickling salt The ratio is 32.6:2.6:2.5:1.3:0.3.

Embodiment 3

[0043] This embodiment uses a meat-derived complex enzyme regulation method, using the same method as in Example 1, the difference is that sodium chloride, potassium chloride, calcium chloride, magnesium chloride, and zinc chloride are used in pickling salt The ratio is 28.3:2.6:2.5:4.2:0.8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com