Low-impurity fatty acid amide propyl tertiary amine production process and device

A fatty amidopropyl tertiary amine and production device technology, applied in the field of surfactants, can solve problems such as shortening the production cycle and reducing production costs, and achieve the effects of convenient equipment configuration, long service life, and reduced labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

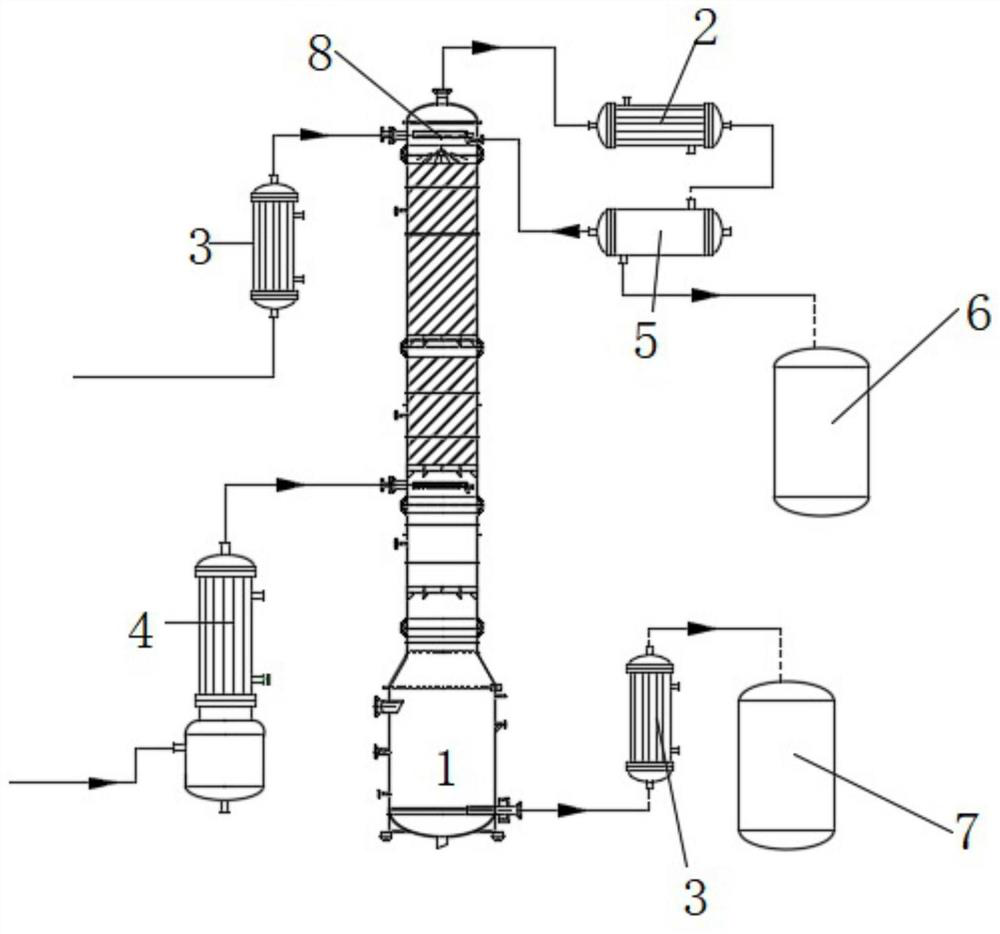

Method used

Image

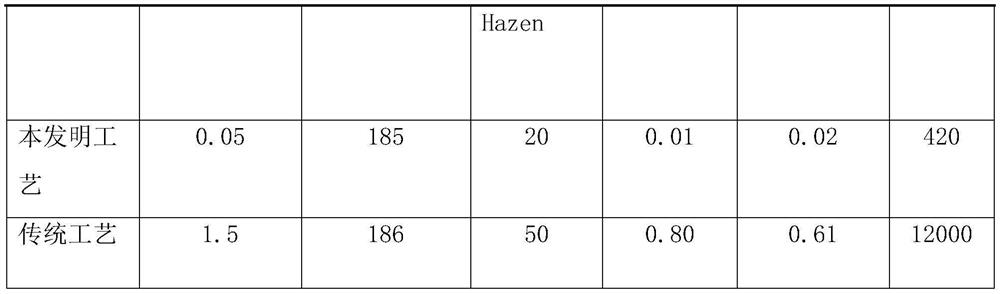

Examples

Embodiment 1

[0031] The present embodiment provides a kind of production technology of the fatty amidopropyl tertiary amine of low impurity, comprises the following steps:

[0032] 1) The material dimethylaminopropylamine is heated into a gas through a reboiler, and the gas dimethylaminopropylamine enters the tower from the tray plate in the middle section of the rectification tower, and passes through the packing of the rectification tower from bottom to top;

[0033] 2) The fatty acid material is heated by a heat exchanger, vaporized by an atomizer, sprayed into the rectification tower from the upper part of the rectification tower, and directly contacts with the gas dimethylaminopropylamine for amidation reaction, and the temperature of the heater is controlled at 150°C; The molar ratio of aminopropylamine to fatty acid substance is 1.0:1.0;

[0034] 3) The fatty acyl dimethyl tertiary amine obtained by the amidation reaction flows back to the bottom of the rectification column, and ret...

Embodiment 2

[0036] The present embodiment provides a kind of production technology of the fatty amidopropyl tertiary amine of low impurity, comprises the following steps:

[0037] 1) The material dimethylaminopropylamine is heated into a gas through a reboiler, and the gas dimethylaminopropylamine enters the tower from the tray plate in the middle section of the rectification tower, and passes through the packing of the rectification tower from bottom to top;

[0038] 2) The fatty acid material is heated by a heat exchanger, vaporized by an atomizer, sprayed into the rectification tower from the upper part of the rectification tower, and directly contacts with the gas dimethylaminopropylamine for amidation reaction, and the temperature of the heater is controlled at 250°C; The molar ratio of aminopropylamine and fatty acid substance is 1.05:1.0;

[0039] 3) The fatty acyl dimethyl tertiary amine obtained by the amidation reaction flows back to the bottom of the rectification column, and r...

Embodiment 3

[0041] The present embodiment provides a kind of production technology of the fatty amidopropyl tertiary amine of low impurity, comprises the following steps:

[0042] 1) The material dimethylaminopropylamine is heated into a gas through a reboiler, and the gas dimethylaminopropylamine enters the tower from the tray plate in the middle section of the rectification tower, and passes through the packing of the rectification tower from bottom to top;

[0043] 2) The fatty acid material is heated by a heat exchanger, vaporized by an atomizer, sprayed into the rectification tower from the upper part of the rectification tower, and directly contacts with the gas dimethylaminopropylamine for amidation reaction, and the temperature of the heater is controlled at 200°C; The molar ratio of aminopropylamine and fatty acid substance is 1.02:1.0;

[0044] 3) The fatty acyl dimethyl tertiary amine obtained by the amidation reaction flows back to the bottom of the rectification column, and r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com