A method for improving the performance uniformity of high carbon steel wire rod in the same circle

A uniform, high-carbon steel technology, applied in the field of steel rolling production, can solve problems such as the mismatch between bulk density and air volume, large lateral temperature fluctuations, large fluctuations in wire rod performance, etc., to achieve simple processing, low equipment transformation costs, The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

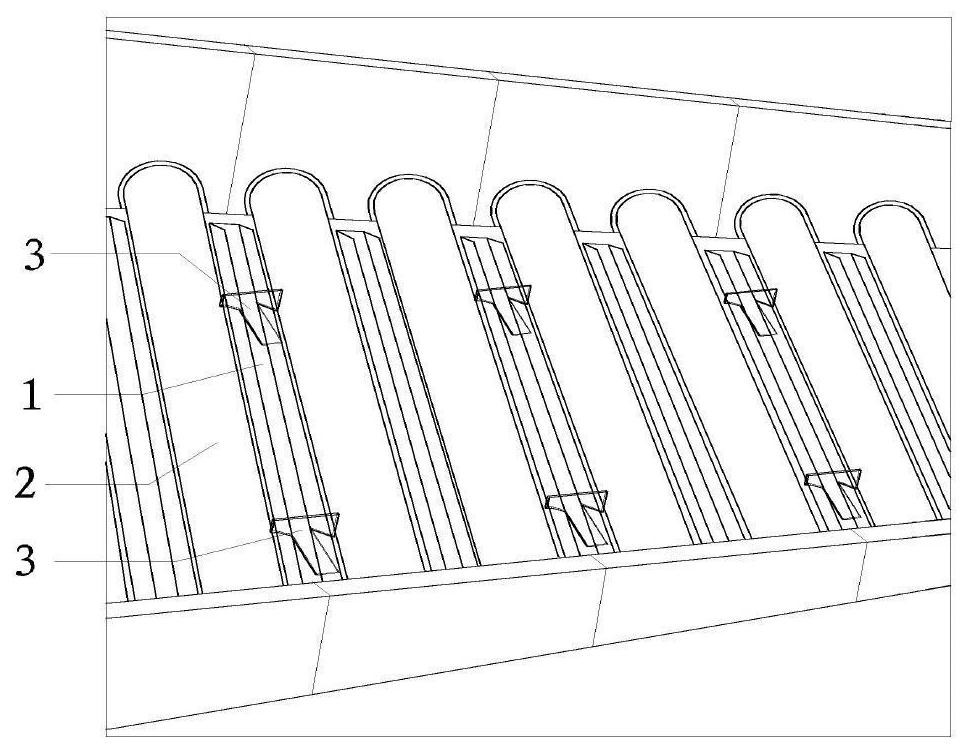

[0033]Implemented in 11mm high carbon steel wire rod, the internal control tensile strength is ≥1050MPa. The wire rod contains 0.72% mass fraction of C and 0.36% mass fraction of Cr. After the wire rod is spun, it is cooled on the Steyrmore air-cooling line, and the lateral cooling is uniform by adding an air baffle device on the Steyrmore. The wind deflector is installed on the odd-numbered exhaust duct outlet of the 4-40m roller table, located 0.21m inside the overlap point, one on the left and one on the left, and one on the left, and the installation direction is perpendicular to the air duct outlet.

[0034] Control the spacing and cooling speed of the adjacent two circles of wire rods in sections, among which: the spinning temperature is 889°C, and the distance between the two adjacent circles of wire rods after spinning is S i =DπV i / V, unit m; control the final rolling speed V = 58m / s, the diameter of the ring after spinning D = 1.28m, S i The settings are shown in ...

Embodiment 2

[0038] Implemented in 12mm high carbon steel wire rod, the internal control tensile strength is ≥1100MPa. The wire rod contains 0.76% mass fraction of C and 0.35% mass fraction of Cr. After the wire rod is spun, it is cooled on the Steyrmore air-cooling line, and the lateral cooling is uniform by adding an air baffle device on the Steyrmore. The wind deflector is installed on the odd-numbered exhaust duct outlet of the 4-40m roller table, located 0.23m inside the overlap point, one on the left and right, and the installation direction is perpendicular to the air duct outlet.

[0039] Control the spacing and cooling speed of the adjacent two circles of wire rods in sections, among which: the spinning temperature is 884°C, and the distance between the two adjacent circles of wire rods after spinning is S i =DπV i / V, unit m; control the final rolling speed V=46m / s, the diameter of the ring after spinning D=1.35m, S i The settings are shown in Table 1.

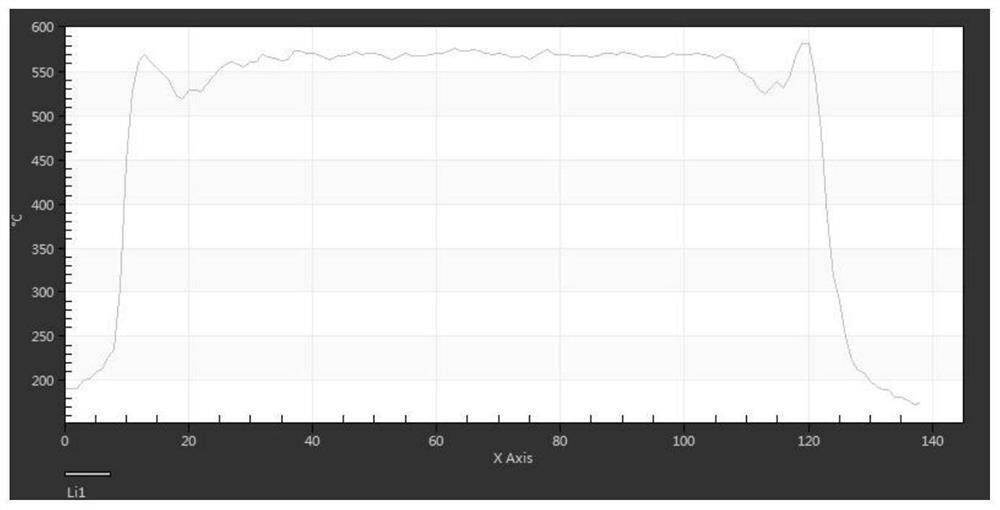

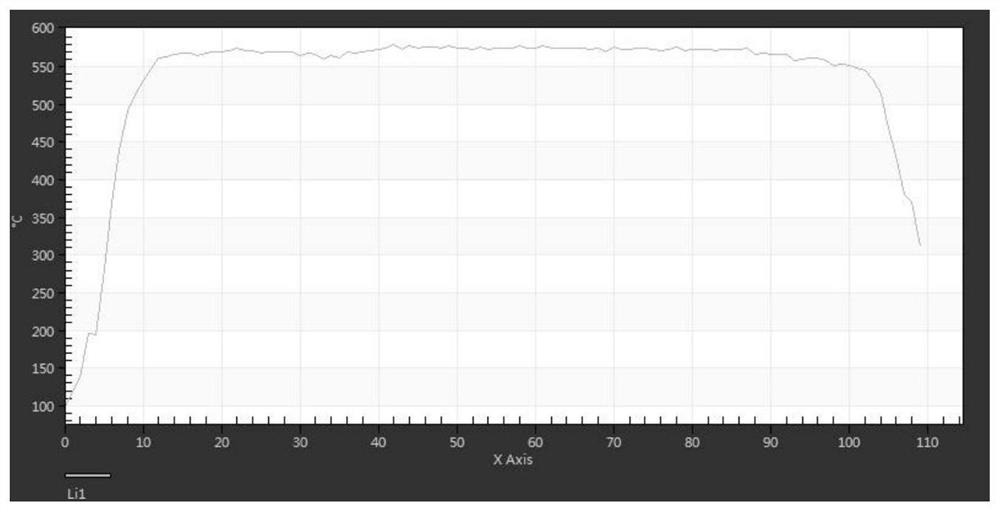

[0040] A thermal infra...

Embodiment 3

[0043] Implemented in 12.5mm high carbon steel wire rod, the internal control tensile strength is ≥1150MPa. The wire rod contains 0.81% mass fraction of C and 0.37% mass fraction of Cr. After the wire rod is spun, it is cooled on the Steyrmore air-cooling line, and the lateral cooling is uniform by adding an air baffle device to the Steyrmore. The wind deflector is installed on the odd-numbered exhaust duct outlet of the 4-40m roller table, located 0.21m inside the overlap point, one on the left and one on the left, and one on the left, and the installation direction is perpendicular to the air duct outlet.

[0044] Control the spacing and cooling speed of the adjacent two circles of wire rods in sections, among which: the spinning temperature is 897°C, and the distance between the two adjacent circles of wire rods after spinning is S i =DπV i / V, unit m; control the final rolling speed V = 42m / s, the circle diameter after spinning D = 1.30m, S i The settings are shown in Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com