Casting method of aluminum alloy extra-high voltage switch shell for gas insulated substation

A technology of gas insulation and aluminum alloy, applied in the direction of casting molding equipment, casting mold, casting mold composition, etc., can solve the problems affecting the quality and service life of the high-voltage switch housing, shrinkage and shrinkage cavity casting quality defects, gap runner cross-section Small area and other problems, to achieve the effect of improving tooling damage, improving messy phenomenon, and good sand mold integrity rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

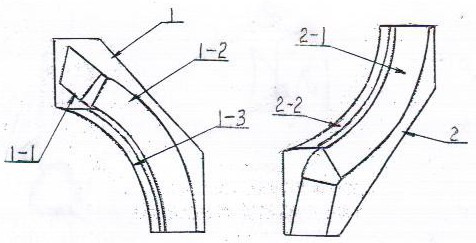

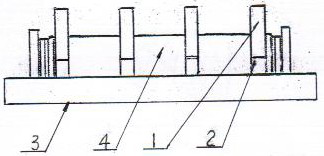

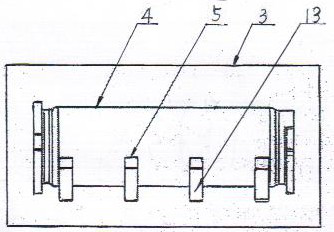

[0017] Examples, see attached Figure 1~6 , the casting method of the aluminum alloy UHV switch housing for the gas insulated substation is to set the upper ring runner 1-2 on the resin sand module 1 of the upper ring runner alone, and outside the upper ring runner 1-2 An upper mold slot runner 1-3 is provided at the edge, and an upper mold annular resin sand module riser 1-1 is arranged above the upper mold annular runner 1-1 and the upper mold slot runner 1-3. On the single resin sand module 2 of the lower annular runner and the upper annular runner 1-2 of the upper annular runner individual resin sand module 1, the lower annular runner 2-1 is set, and the upper mold slot runner 1- 3 corresponds to setting the runner 2-2 for the lower type gap. The amount of furan resin in the raw materials used to make the core is 1% of the total weight of the mixed sand, the amount of supporting curing agent is 50% of the weight of the furan resin, and the rest is silica sand. The above r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com