Double-magnetic-disk magnetic passivation device and passivation method thereof

A dual-disk, magnetic technology, applied in other manufacturing equipment/tools, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of lower polishing effect of the knife, high equipment cost, low passivation efficiency, etc., and achieve time cost Saving, high economy, and the effect of improving the efficiency of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

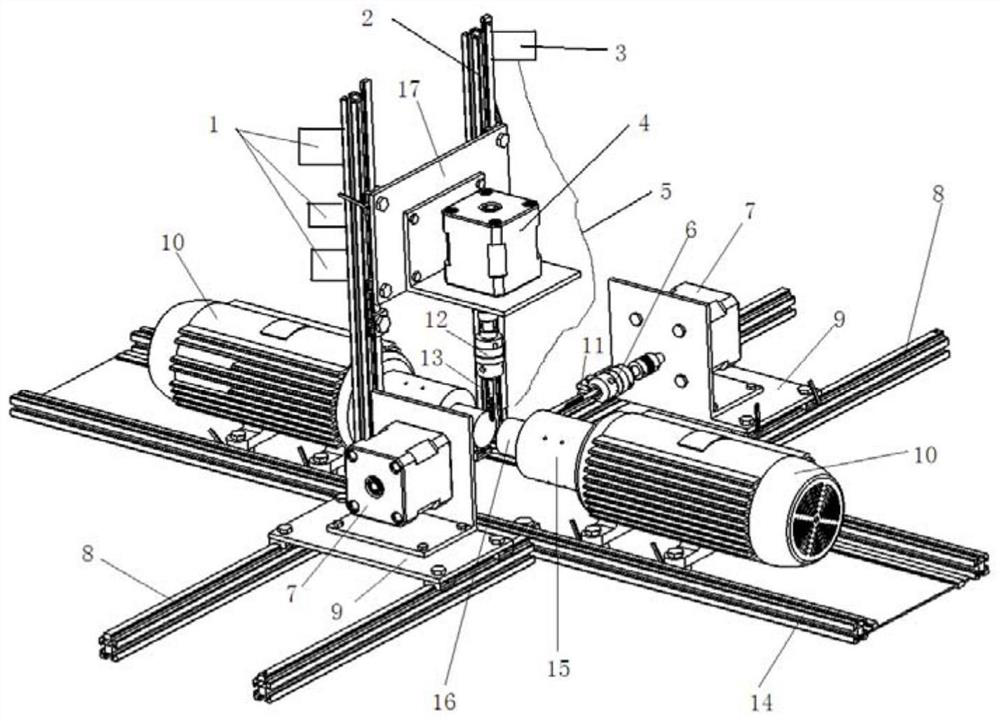

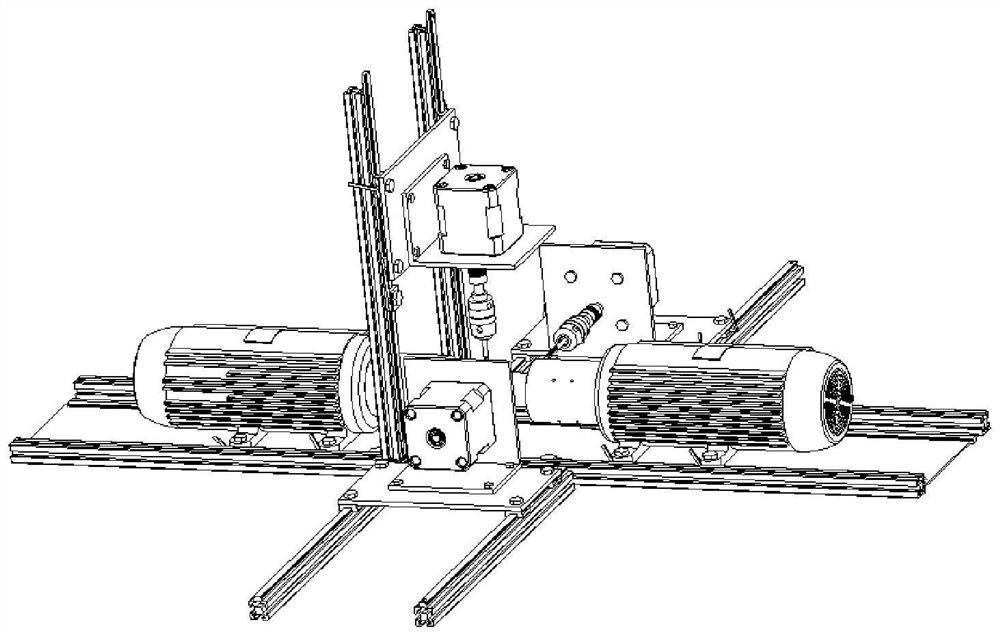

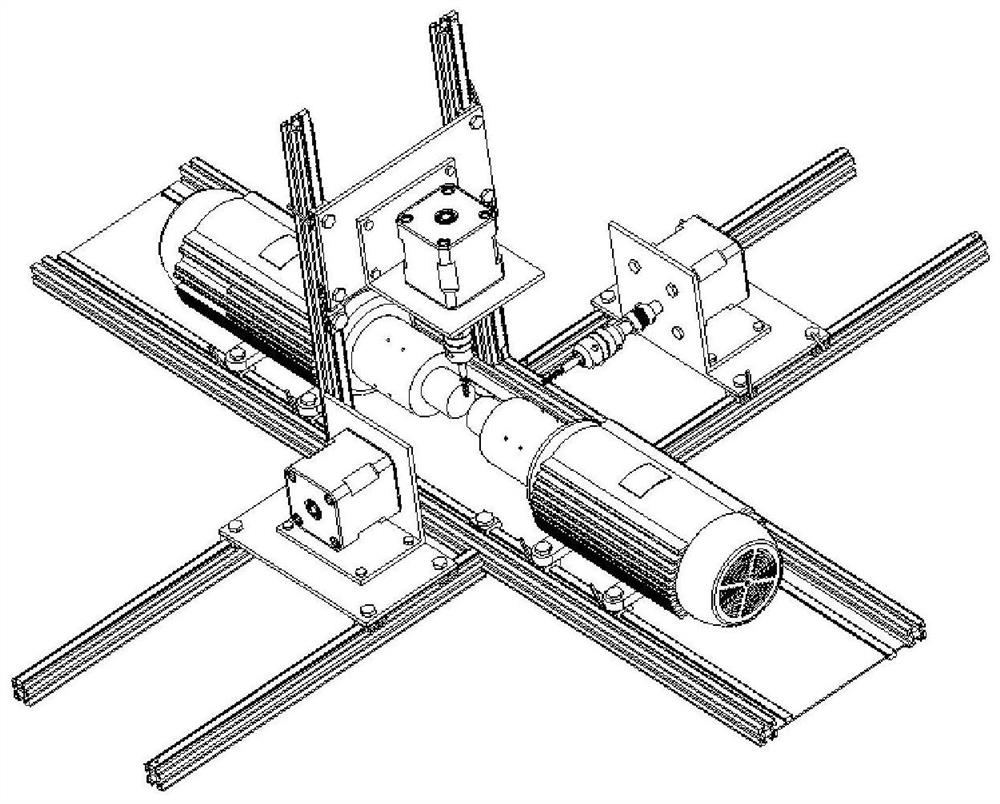

[0019] Embodiment 1: as attached Figure 1~4 As shown, a double-disk magnetic passivation device includes a horizontal frame 14 and a vertical frame 2, the horizontal frame 14 is arranged horizontally, the vertical frame 2 is perpendicular to the horizontal frame 14, and the horizontal frame 14 is provided with two symmetrical Disk motor 10, disk motor 10 connects disk 16 through shaft coupling 15, vertical frame 2 connects cutter motor one 4 through motor seat 17, cutter motor one 4 connects tool chuck one 12 through shaft coupling, and the tool chuck one 12 below A cutter 13 is clamped, and the cutter 13 is located in the gap between the magnetic disks 16. The vertical frame 2 is provided with a grinding fluid pump 3, and the grinding fluid pump 3 sprays grinding fluid to the cutter 13 through the hose 5.

[0020] Further, both sides of the horizontal frame 14 are symmetrically connected with vertical frames 8, the vertical frame 8 and the horizontal frame 14 are perpendicul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com