Yellow lyocell fabric prepared by dyeing osmanthus fragrans with vegetable dye and preparation method of yellow lyocell fabric

A technology of vegetable dyes and sweet-scented osmanthus, applied in dyeing methods, reactive dyes, azo dyes, etc., to achieve the effect of simplifying the dyeing process, high K/S value, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation method of the yellow Lyocell fabric that plant dyestuff osmanthus dyes makes, described method comprises the steps:

[0039] (1) Preparation of yellow plant dye stock solution: wash and mash 10g of sweet-scented osmanthus, steam distillation at 240°C for 120 min, the amount of water steam is 150mL / min, after distillation, collect the filtrate to obtain yellow plant dye stock solution.

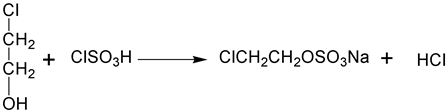

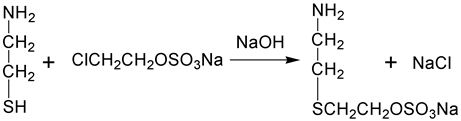

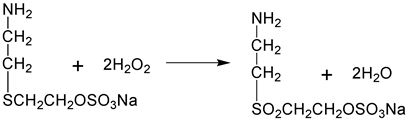

[0040] (2) Chemical modification: Add 1.5mL 5wt% formaldehyde aqueous solution and 0.3g 1-amino-2-sulfate ethyl sulfone ethane to 150mL yellow plant dye stock solution prepared in step (1), and use 30wt% NaOH The lye adjusts the pH of the reaction solution to 10.5, continuously stirs, the reaction time is 90 minutes, and the reaction temperature is 85°C to prepare a modified yellow vegetable dye solution.

[0041] (3) Dyeing: the modified yellow plant dye solution of step (2) is diluted with water to obtain a dyeing solution, the amount of water is 15 times that of the m...

Embodiment 2

[0048] The preparation method of the yellow Lyocell fabric that plant dyestuff osmanthus dyes makes, described method comprises the steps:

[0049] (1) Preparation of yellow plant dye stock solution: wash and mash 10g of sweet-scented osmanthus, steam distillation at 240°C for 120 min, the amount of water steam is 150mL / min, after distillation, collect the filtrate to obtain yellow plant dye stock solution.

[0050] (2) Chemical modification: Add 1.5mL 5wt% formaldehyde aqueous solution and 0.375g 1-amino-2-sulfate ethyl sulfone ethane to 150mL yellow plant dye stock solution prepared in step (1), and use 30wt% NaOH The lye adjusts the pH of the reaction solution to 10.3, continuously stirs, the reaction time is 80 minutes, and the reaction temperature is 80° C. to prepare a modified yellow vegetable dye solution.

[0051] (3) Dyeing: the modified yellow plant dye solution of step (2) is diluted with water to obtain a dyeing solution, the amount of water is 15 times that of t...

Embodiment 3

[0058] The preparation method of the yellow Lyocell fabric that plant dyestuff osmanthus dyes makes, described method comprises the steps:

[0059] (1) Preparation of yellow plant dye stock solution: wash and mash 10g of sweet-scented osmanthus, steam distillation at 240°C for 120 min, the amount of water steam is 150mL / min, after distillation, collect the filtrate to obtain yellow plant dye stock solution.

[0060] (2) Chemical modification: Add 1.5mL 5wt% formaldehyde aqueous solution and 0.25g 1-amino-2-sulfate ethyl sulfone ethane to 150mL yellow vegetable dye stock solution prepared in step (1), and use 30wt% NaOH The lye adjusts the pH of the reaction solution to 10.8, continuously stirs, the reaction time is 100 minutes, and the reaction temperature is 90°C to prepare a modified yellow vegetable dye solution.

[0061] (3) Dyeing: the modified yellow plant dye solution of step (2) is diluted with water to obtain a dyeing solution, the amount of water is 15 times that of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com