Blue lyocell fabric for dyeing hyacinth as vegetable dye and preparation method of blue lyocell fabric

A technology of vegetable dyes and hyacinths is applied in the field of blue lyocell fabrics and their preparation to achieve the effects of simplifying the dyeing process, reducing environmental pollution and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation method of the blue lyocell fabric that dyeing of vegetable dye hyacinth is made, described method comprises the steps:

[0038] (1) Extraction of blue toner: pick the hyacinth petals, wash them first and mash them, and use supercritical CO 2 Extraction, the pressure is 30MPa, the extraction temperature is between 45°C, the extraction time is 3h, CO 2 The flow rate is: 14L / h, ethanol is used as an entrainer, the extract is distilled under reduced pressure at 70°C for 4 hours, the pressure is -40kPa, the ethanol solvent is removed, and the blue toner is prepared for use.

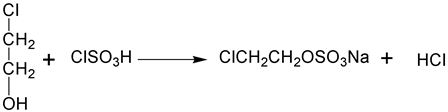

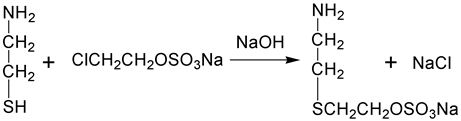

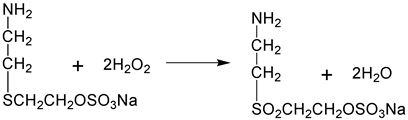

[0039] (2) Preparation of modified blue vegetable dye: In 40mL of aqueous solution, add 1g of blue toner prepared in step (1), 4mL of 5wt% formaldehyde aqueous solution and 0.2g of 1-amino-2-sulfate ethyl sulfone ethane , use 30wt% NaOH lye to adjust the pH of the reaction solution to 10.5, keep stirring, the reaction time is 70 minutes, the reaction temperature is 60 ° C, after the rea...

Embodiment 2

[0047] The preparation method of the blue lyocell fabric that dyeing of vegetable dye hyacinth is made, described method comprises the steps:

[0048] (1) Extraction of blue toner: pick the hyacinth petals, wash them first and mash them, and use supercritical CO 2 Extraction, the pressure is 25MPa, the extraction temperature is between 40°C, the extraction time is 1 h, CO 2 The flow rate is: 10L / h, ethanol is used as an entrainer, the extract is distilled under reduced pressure at 60°C for 3 hours, the pressure is -30kPa, the ethanol solvent is removed, and the blue toner is prepared for use.

[0049] (2) Preparation of modified blue vegetable dye: In 30mL of aqueous solution, add 1g of blue toner prepared in step (1), 3mL of 5wt% formaldehyde aqueous solution and 0.1g of 1-amino-2-sulfate ethyl sulfone ethyl alkane, adjust the pH of the reaction solution with 30wt% NaOH lye to be 10.2, stir constantly, the reaction time is 60 minutes, and the reaction temperature is 55 ° C. ...

Embodiment 3

[0057] The preparation method of the blue lyocell fabric that dyeing of vegetable dye hyacinth is made, described method comprises the steps:

[0058] (1) Extraction of blue toner: pick the hyacinth petals, wash them first and mash them, and use supercritical CO 2 Extraction, the pressure is 40 MPa, the extraction temperature is between 50°C, the extraction time is 5 h, CO 2 The flow rate is: 18L / h, ethanol is used as an entrainer, the extract is distilled under reduced pressure at 80°C for 5 hours, the pressure is -50kPa, the ethanol solvent is removed, and the blue toner is prepared for use.

[0059] (2) Preparation of modified blue vegetable dye: In 50mL of aqueous solution, add 1g of blue toner prepared in step (1), 5mL of 5wt% formaldehyde aqueous solution and 0.3g of 1-amino-2-sulfate ethyl sulfone ethyl alkane, adjust the pH of the reaction solution with 30wt% NaOH lye to be 10.9, stir constantly, the reaction time is 80 minutes, and the reaction temperature is 65 ° C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com