Cigarette paper capable of improving cigarette ash column whiteness as well as preparation method and application thereof

A technology of cigarette paper and ash column, which is applied in the field of cigarette paper and its preparation to improve the whiteness of cigarette ash column, which can solve the problems of cigarette paper turning over, the influence of various indicators of cigarettes, and the increase of cigarette tar release, so as to improve the whiteness of cigarettes. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

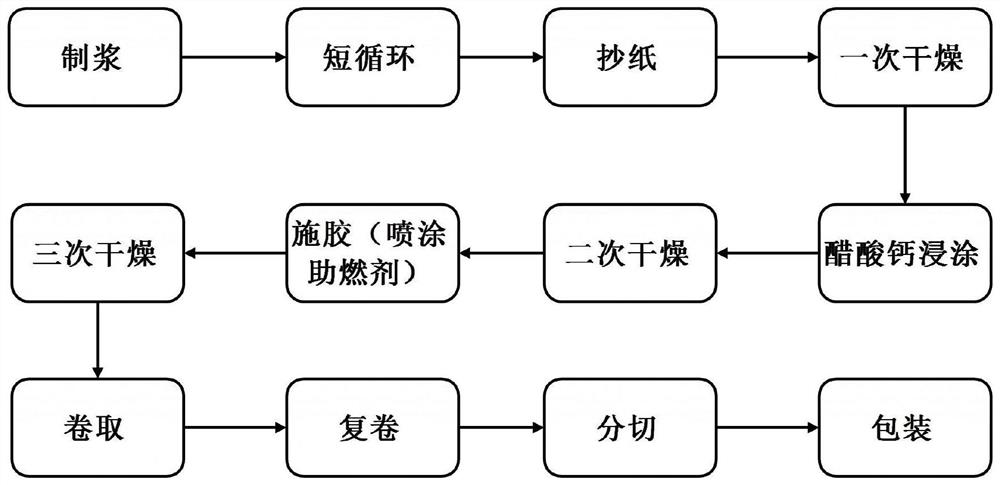

[0032] in the attached figure 1 In the cigarette paper manufacturing process shown, the amount of calcium acetate added in the calcium acetate dipping process is 30% of the total mass of calcium carbonate and calcium acetate; the final cigarette paper produced is 30g / m 2 , 60CU.

[0033] Replace conventional 30g / m 2 , 60CU cigarette paper products are made into cigarettes (2#), and compared with the original cigarettes (1#), the results are as follows:

[0034] Sample serial number gray column whiteness Tuff index Tar release (mg) 1# 129.2 6.0 10.0 2# 146.9 4.1 10.0

[0035] It can be seen from the above table that compared with the original cigarette samples, the ash column whiteness and ash index of the same standard cigarette paper (grammage and air permeability) produced by this method are significantly improved, and the smoke emission is basically the same. Change. According to the sensory evaluation, there is no significant differenc...

Embodiment 3

[0037] in the attached figure 1 In the cigarette paper manufacturing process shown, the amount of calcium acetate added in the calcium acetate dipping process is 20% of the total mass of calcium carbonate and calcium acetate; the final cigarette paper produced is 38g / m 2 , 50CU.

[0038] Replace conventional 38g / m 2 , 50CU cigarette paper products are made into cigarettes (2#), and compared with the original cigarettes (1#), the results are as follows:

[0039] Sample serial number gray column whiteness Tuff index Tar release (mg) 1# 136.2 5.2 11.0 2# 149.3 3.4 11.0

[0040]It can be seen from the above table that compared with the original cigarette samples, the ash column whiteness and ash index of the same standard cigarette paper (grammage and air permeability) produced by this method are significantly improved, and the smoke emission is basically the same. Change. According to the sensory evaluation, there is no significant difference...

Embodiment 4

[0042] in the attached figure 1 In the cigarette paper manufacturing process shown, the amount of calcium acetate added in the calcium acetate dipping process is 15% of the total mass of calcium carbonate and calcium acetate; the final cigarette paper produced is 28g / m 2 , 70CU.

[0043] Replace conventional 28g / m 2 , 70CU cigarette paper products are made into cigarettes (2#), and compared with the original cigarettes (1#), the results are as follows:

[0044] Sample serial number gray column whiteness Tuff index Tar release (mg) 1# 108.1 8.0 10.0 2# 132.1 5.2 10.0

[0045] It can be seen from the above table that compared with the original cigarette samples, the ash column whiteness and ash index of the same standard cigarette paper (grammage and air permeability) produced by this method are significantly improved, and the smoke emission is basically the same. Change. According to the sensory evaluation, there is no significant differenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com