Puncture discharge equipment for new energy automobile lithium battery recycling

A new energy vehicle, lithium battery technology, applied in battery recycling, secondary battery charging/discharging, battery circuit devices, etc., can solve problems such as low operating efficiency, waste of resources, damage, etc., and achieve the goal of improving discharge efficiency and improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

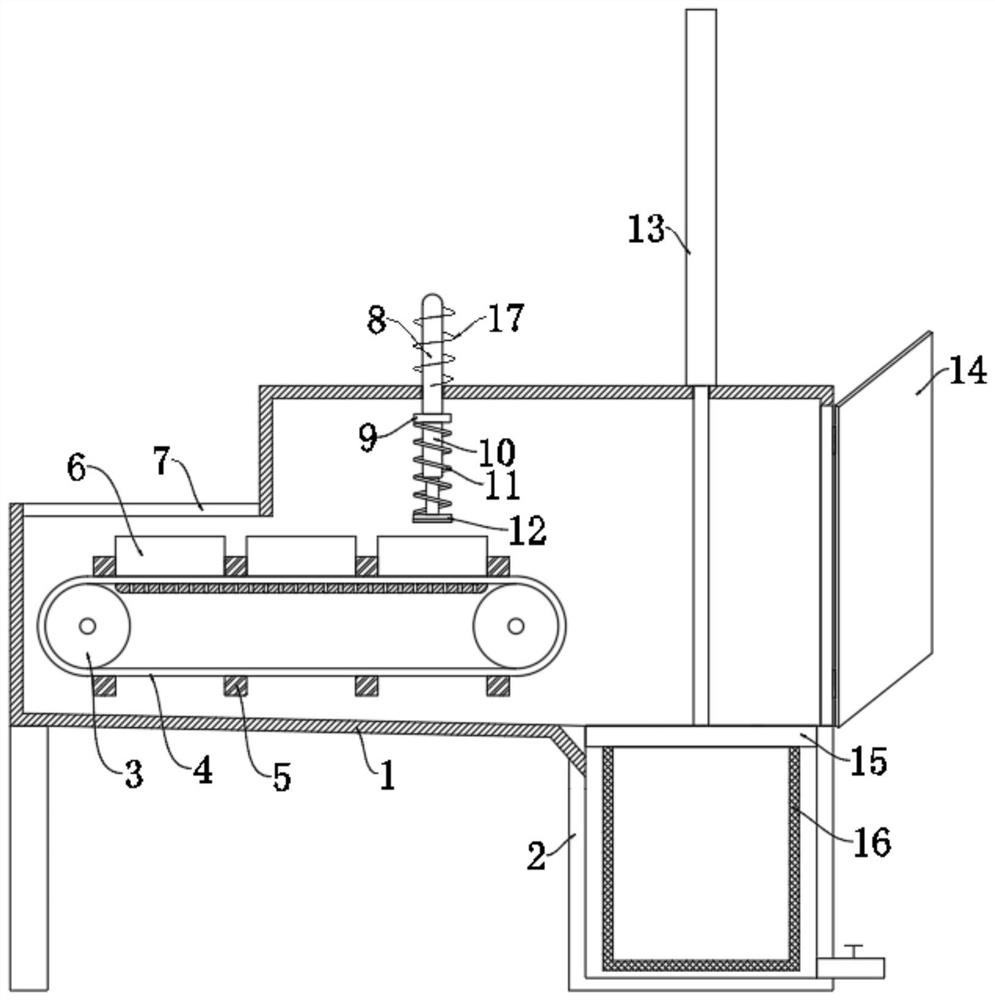

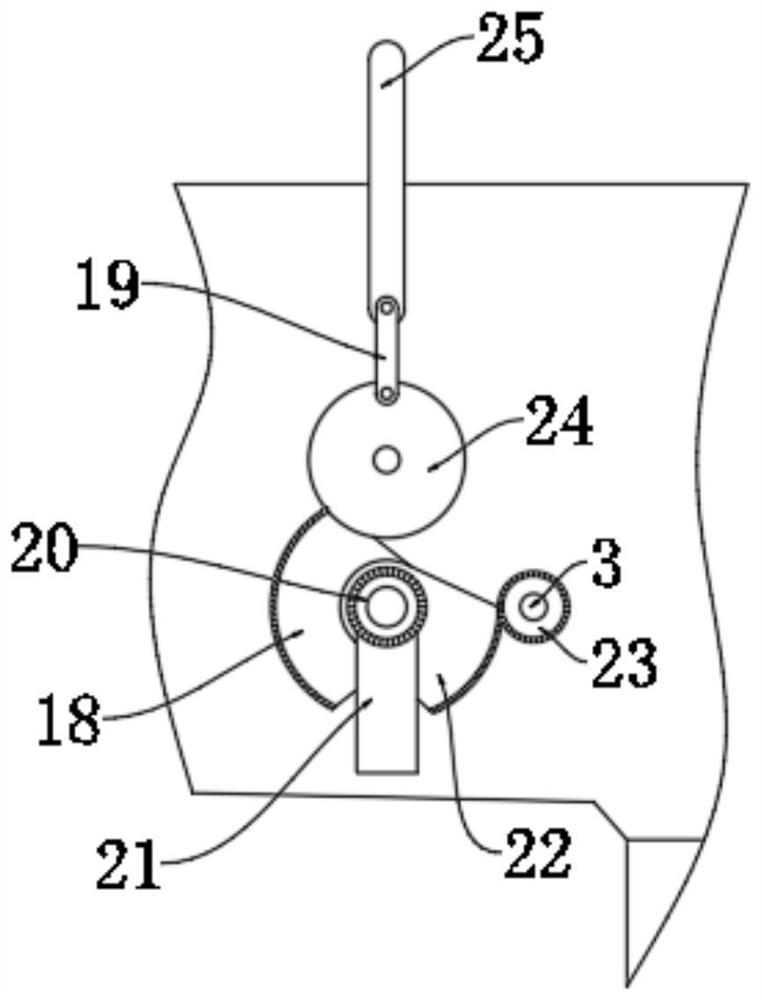

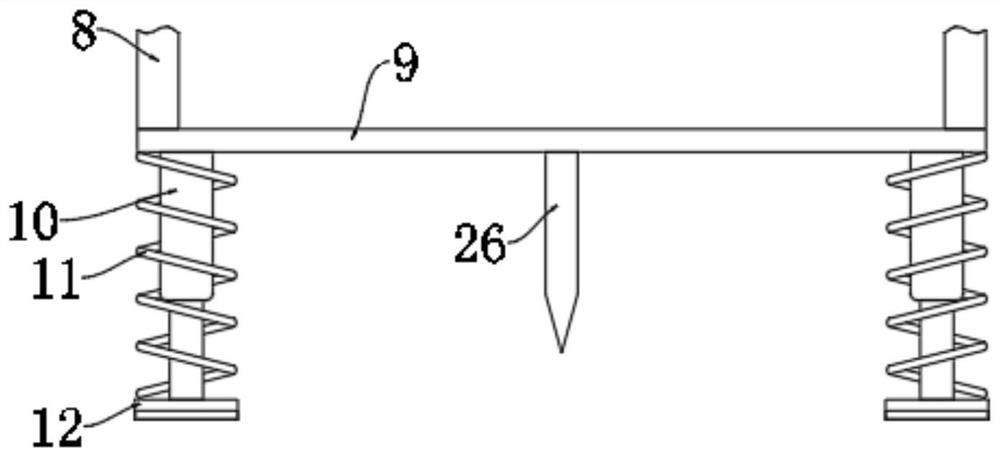

[0027] refer to Figure 1-4 , a new energy vehicle lithium battery recycling puncture discharge equipment, including a puncture box 1, the puncture box 1 is installed along the horizontal direction with two transmission rollers 3, the two transmission rollers 3 are connected to a conveyor belt 4, and the belt surface of the conveyor belt 4, etc. The limit bars 5 are arranged at intervals, and the setting of the limit bars 5 can make the batteries 6 be placed neatly in sequence. The end of the transmission roller 3 penetrates the puncture box 1 and is fixedly connected with the first driven gear 23. The puncture box 1 is located on the side of the conveyor belt 4 A feed port 7 is provided above, and a discharge box 2 is provided below the puncture box 1 on the other side of the conveyor belt 4, and discharge liquid is stored in the discharge box 2, and a puncture mechanism located above the conveyor belt 4 is provided on the inner top of the puncture box 1 to puncture The outer...

Embodiment 2

[0033] refer to Figure 5-7 Compared with Embodiment 1, the advantage of this embodiment is that the storage net cylinder 16 of this embodiment is connected to the lifting frame 15 in rotation, and the side wall of the storage net cylinder 16 is fixedly sleeved with a ring gear 35, and the discharge box 2 A connecting shaft 33 that is rotationally connected to the side wall of the connecting shaft 33 is penetrated, and one end of the connecting shaft 33 is fixedly connected with a second bevel wheel 34 meshing with the ring gear 35, and the other end of the connecting shaft 33 is fixedly connected with the first bevel wheel 32. The bottom of the puncture box 1 is fixedly connected with a wheel frame 29, the wheel frame 29 is rotatably connected with a first transmission wheel 30, and the wheel shaft of the first transmission wheel 30 is fixedly connected with a crown gear 31, the crown gear 31 meshes with the first bevel wheel 32, and the rotating shaft 27 is fixedly sleeved w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com