Turbomachine

A technology of turbines and turbine casings, applied in the lubrication of turbine/propulsion devices, mechanical equipment, engine components, etc., can solve problems such as damage to turbine efficiency, increase thermal friction loss of impellers, etc., to achieve the effect of improving working methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

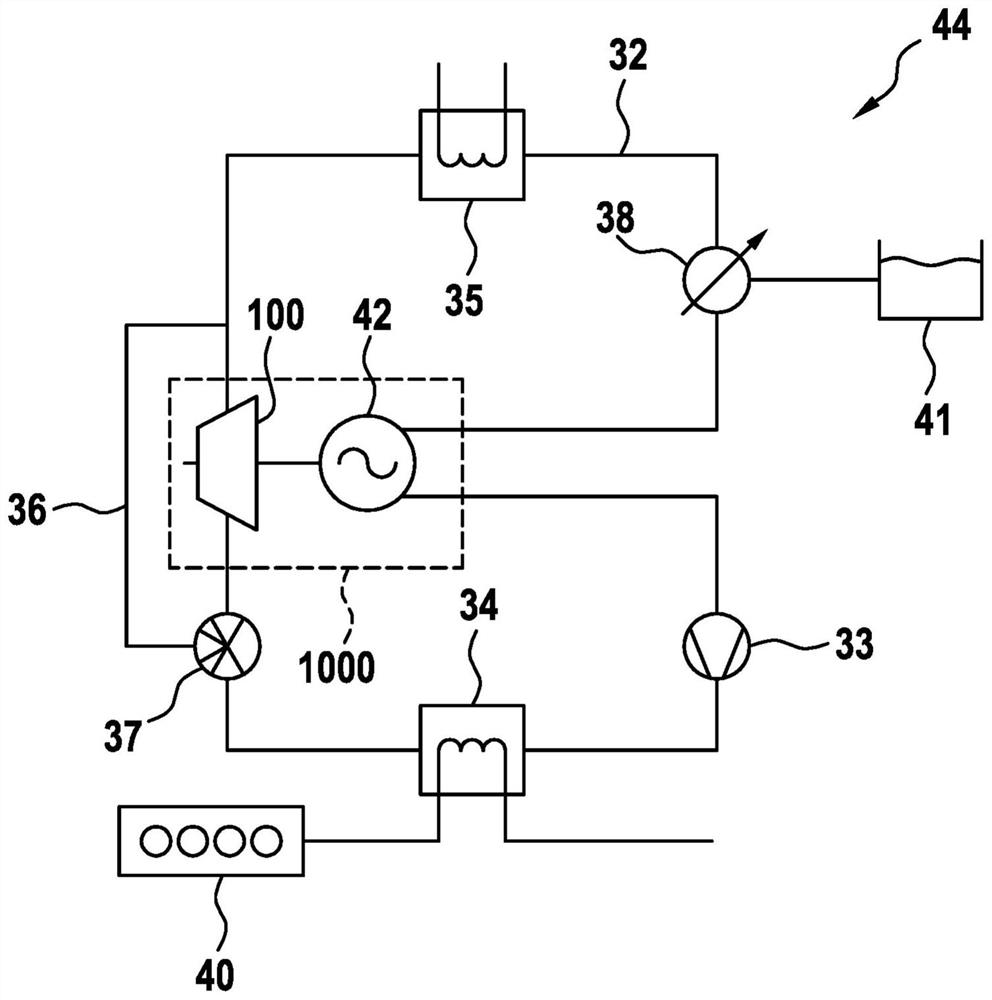

[0025] figure 1 The known waste heat recovery system 44 of the internal combustion engine 40 is shown schematically, wherein only the main region is shown.

[0026] The waste heat recovery system 44 has a circuit 32 that directs the working medium, and the circuit includes a fluid pump 33, an evaporator 34, a turbine 100, and a condenser 35 in the flow direction of the working medium. Here, the condenser 35 can, for example, be coupled to the cooling system of the internal combustion engine 40.

[0027] The bypass line 36 is connected in parallel with the turbine 100. The mass stream of the working medium can be assigned to the turbine 100 and / or bypass line 36 by the bypass valve 37 as needed.

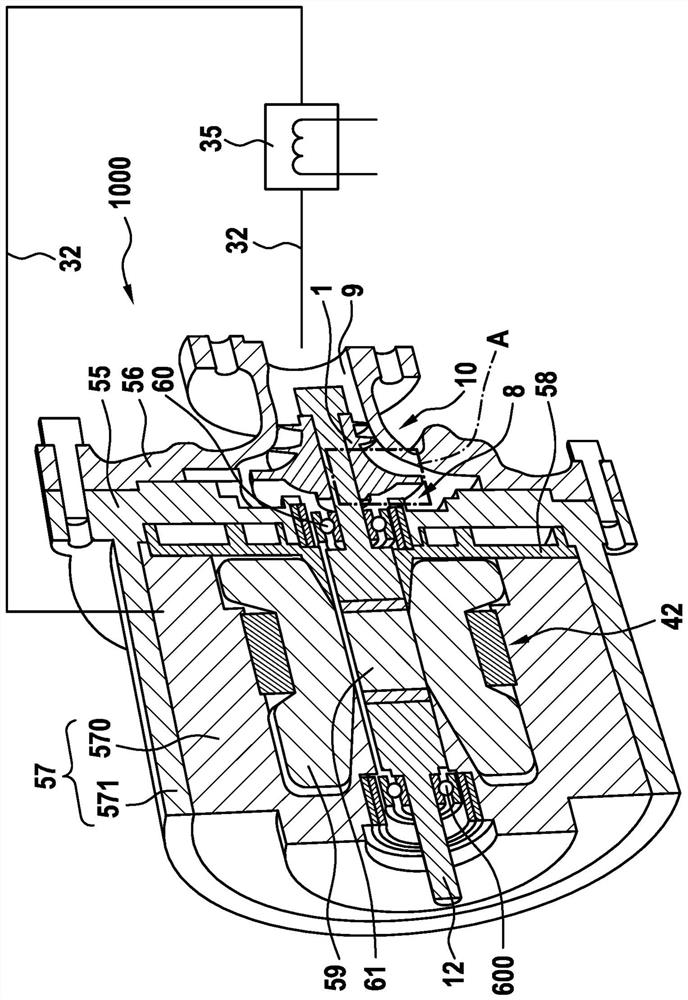

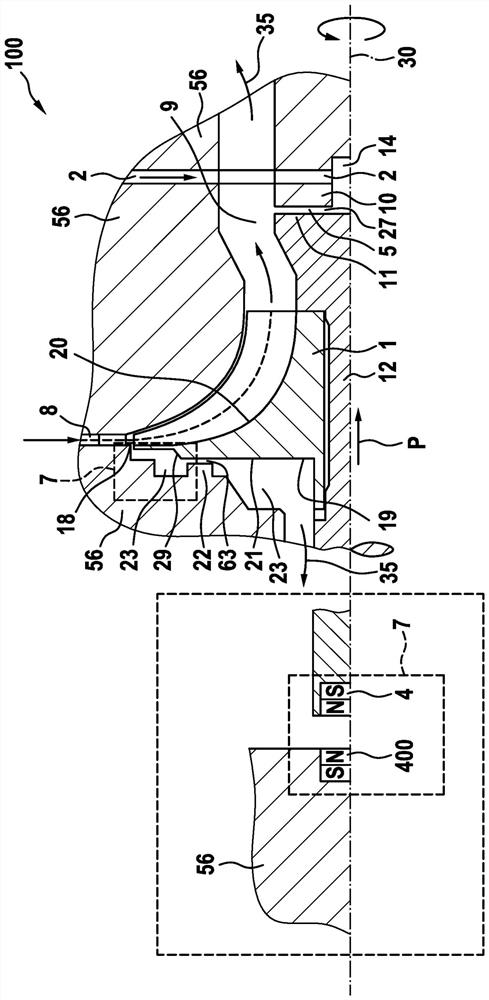

[0028] Here, the turbine 100 is part of the turbine unit 1000. The turbine unit 1000 additionally includes a generator 42, in addition, optionally also include bypass valve 37 and bypass line 36. The generator 42 converts the mechanical energy generated in the turbine 100 into electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com