Ibuprofen suspension and preparation method thereof

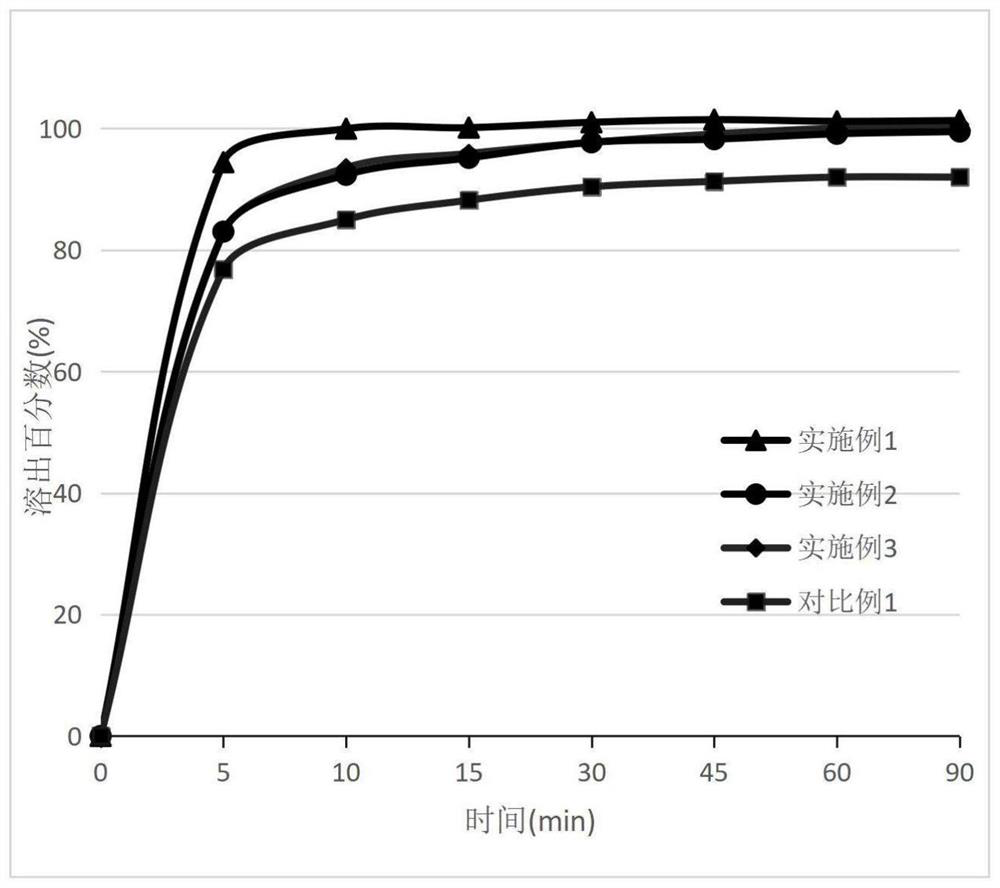

A technology of suspension and aqueous solution, applied in the field of medicine, can solve the problems of low dissolution rate and poor bioavailability, and achieve the effect of high dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

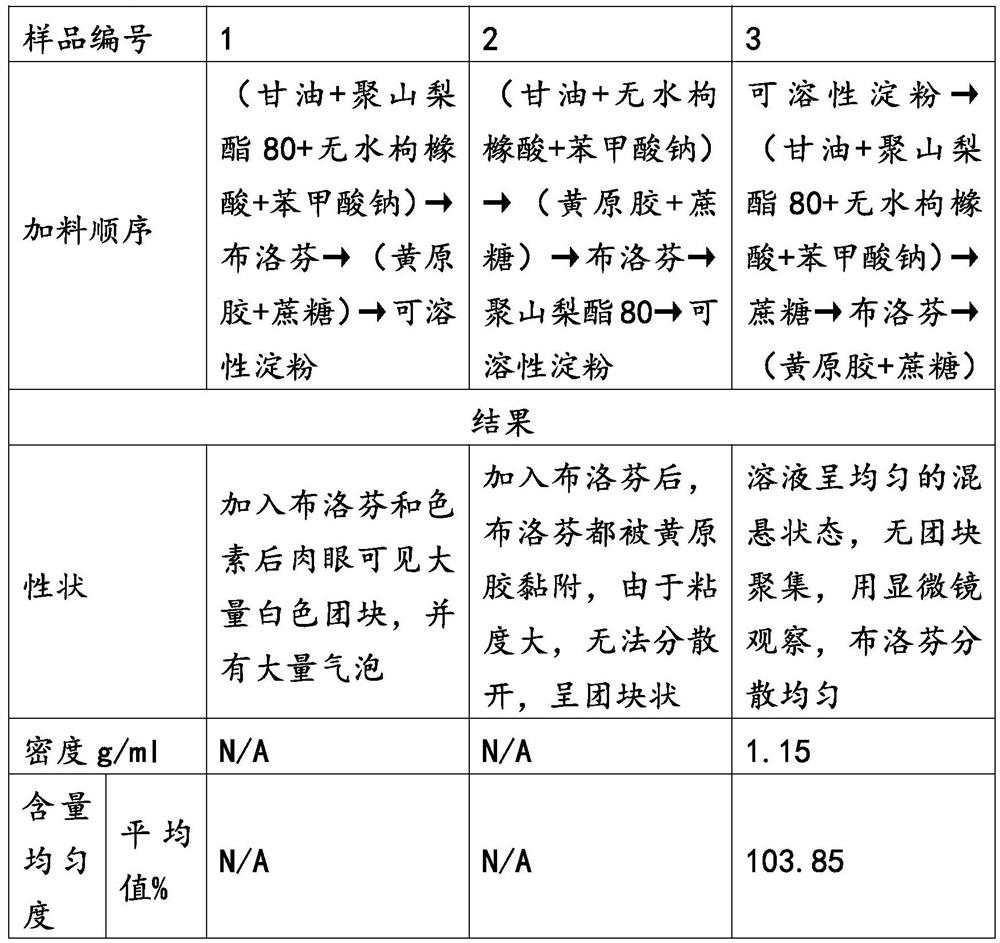

Method used

Image

Examples

Embodiment 1

[0037] Weigh 1620.0g of purified water and pour it into the liquid mixing tank I, heat it to about 100°C while stirring, the stirring speed is 60HZ (3600rpm), add 104.8g of soluble starch, stir for 20min to dissolve completely. Cool down to 40-50°C, add 800.0g glycerin, 17.6g anhydrous citric acid, 6.4g polysorbate 80 and 16.0g sodium benzoate in sequence, wash the remaining material in the beaker with an appropriate amount of purified water, stir for 20 minutes, and dissolve completely.

[0038] Slowly add the prescription amount of 80% sucrose (2400*0.8=1920g), continue to stir for 20min after adding, stir until completely dissolved, then add 160g ibuprofen (D90=45.0μm), 0.176g sunset yellow, 0.016g allura red, Stirring was continued for 40 min.

[0039] Weigh 2430g of purified water and pour it into the liquid mixing tank II, add the remaining 20% sucrose (2400*0.2=480g) and 28.8g xanthan gum (mixed manually for 10min), stir for 30min until the sucrose is completely disso...

Embodiment 2

[0043] Weigh 1620.0g of purified water and pour it into the liquid mixing tank I, heat it to about 100°C while stirring, the stirring speed is 60HZ (3600rpm), add 104.8g of soluble starch, stir for 20min to dissolve completely. Cool down to 40-50°C, add 800.0g glycerin, 17.6g anhydrous citric acid, 6.4g polysorbate 80 and 16.0g sodium benzoate in sequence, wash the remaining material in the beaker with an appropriate amount of purified water, stir for 20 minutes, and dissolve completely.

[0044] Slowly add the prescription amount of 80% sucrose (2400*0.8=1920g), continue to stir for 20min after adding, stir until completely dissolved, then add 160g ibuprofen (D90=50.0μm), 0.176g sunset yellow, 0.016g allura red, Stirring was continued for 40 min.

[0045] Weigh 2430g of purified water and pour it into the liquid mixing tank II, add the remaining 20% sucrose (2400*0.2=480g) and 28.8g xanthan gum (mixed manually for 10min), stir for 30min until the sucrose is completely disso...

Embodiment 3

[0049] Weigh 1620.0g of purified water and pour it into the liquid mixing tank I, heat it to about 100°C while stirring, the stirring speed is 60HZ (3600rpm), add 104.8g of soluble starch, stir for 20min to dissolve completely. Cool down to 40-50°C, add 800.0g glycerin, 17.6g anhydrous citric acid, 6.4g polysorbate 80 and 16.0g sodium benzoate in sequence, wash the remaining material in the beaker with an appropriate amount of purified water, stir for 20 minutes, and dissolve completely.

[0050] Slowly add the prescription amount of 80% sucrose (2400*0.8=1920g), continue to stir for 20min after adding, stir until completely dissolved, then add 160g ibuprofen (D90=65.0μm), 0.176g sunset yellow, 0.016g allura red, Stirring was continued for 40 min.

[0051] Weigh 2430g of purified water and pour it into the liquid mixing tank II, add the remaining 20% sucrose (2400*0.2=480g) and 28.8g xanthan gum (mixed manually for 10min), stir for 30min until the sucrose is completely disso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com