Assembly type structure system and construction method thereof

A construction method and prefabricated technology, applied in building components, building structures, roofs, etc., can solve the problems of inability to take into account construction difficulty and construction efficiency, poor construction space environment, and inability to guarantee structural performance, and achieve convenient transportation and hoisting. The effect of construction, convenient construction and large joint surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

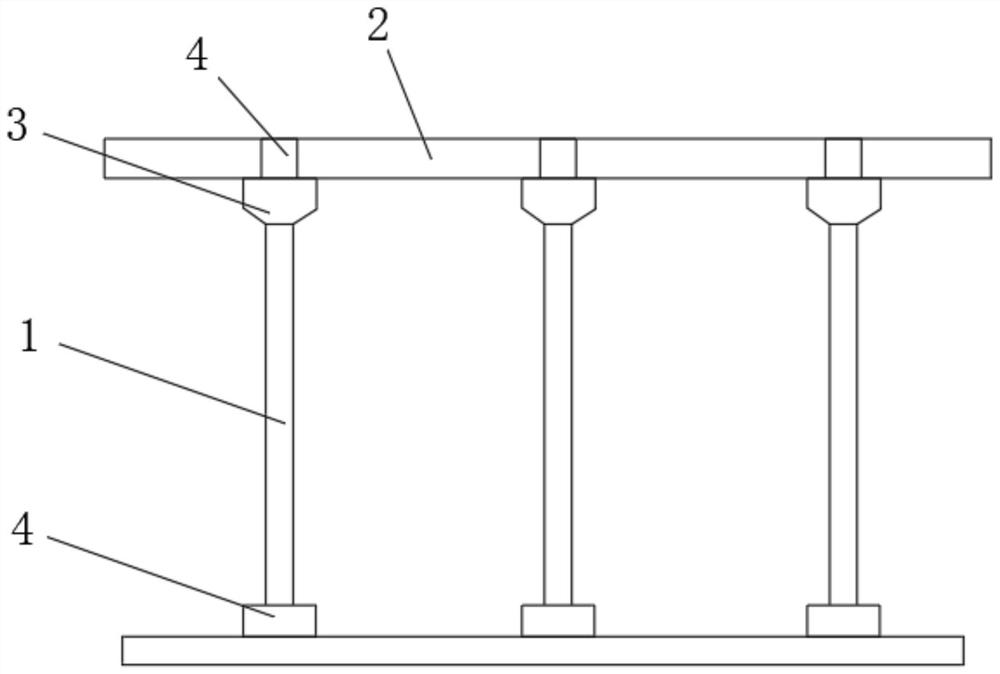

[0023] refer to figure 1 , the technical solution of a prefabricated structural system provided in this embodiment is as follows:

[0024] An assembled structural system, comprising a double-sided laminated shear wall panel 1, a prestressed hollow roof panel 2, and a prefabricated corbel 3; the double-sided laminated shear wall panel 1 is The pouring node 4 between the wall panel 1 and the built floor a is fixed on the built floor a; the prefabricated corbel 3 passes through the pouring node between the prefabricated corbel 3 and the double-sided laminated shear wall 1 4 is fixed on the double-sided laminated shear wall panel 1; the hollow roof panel 2 is fixed on the prefabricated corbel 3 through the pouring node 4 between the hollow roof panel 2 and the prefabricated corbel 3.

[0025] A prefabricated structural system of this embodiment uses double-sided laminated shear wall panels 1 and prestressed hollow roof panels 2 as wall panels and roofing, which greatly reduces th...

Embodiment 2

[0028] This embodiment provides a construction method for the prefabricated structural system described in Embodiment 1. The technical solution is as follows, including the following steps:

[0029] S1, prefabricated double-sided laminated shear wall panel 1, prestressed hollow roof panel 2, and prefabricated corbel beam 3, and transported to the construction site;

[0030] S2, hoisting the double-sided laminated shear wall panel 1 on the built floor a;

[0031] S3, pouring the pouring node 4 between the built base plate a and the double-sided laminated shear wall panel 1, and completing the connection between the built base plate a and the double-sided laminated shear wall panel 1;

[0032] S4, lapping the prefabricated corbel beam 3 on the double-sided laminated shear wall panel 1;

[0033] S5, pouring the pouring node 4 between the double-sided laminated shear wall panel 1 and the prefabricated corbel 3, and completing the connection between the double-sided laminated shea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com