Scramjet self-adaptive perforation fluctuation fracturing synergy system

A self-adaptive and fracturing technology, applied in the direction of mining fluid, earthwork drilling, explosives, etc., can solve the problems of high energy, casing damage, wellbore and formation damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

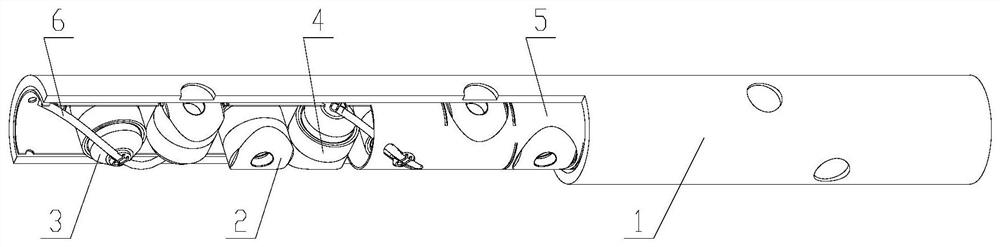

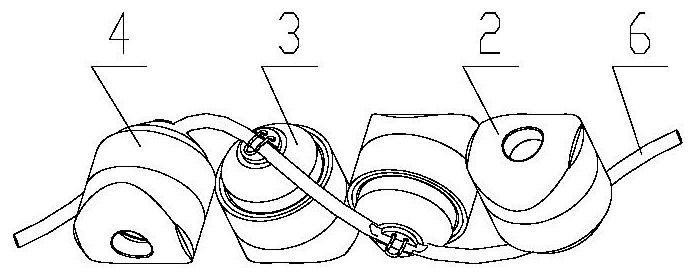

Embodiment 1

[0112] Such as Figure 6-Figure 11 As shown: the scram adaptive energy-releasing perforating charge 3 sequentially includes an adaptive active metal charge cover 301, an explosive charge column 302, and a double-layer energetic shell 303 from the inside to the outside, and the outer shell of the double-layer energetic shell 303 The body 30301 is a carbon steel shell, and the inner layer is an energetic material layer 30302 . The double-layer energetic shell 303 includes an integral hollow cylindrical section and a hollow frustum of a cone, the upper end of which is open, and the self-adaptive active metal drug cover 301 is a conical cover, the bottom of which is fixed on the cylindrical section of the double-layer energetic shell On the lower inner wall of the cylinder section, the lower end of the cylindrical section is sealed, and the explosive grain column 302 is located in the cavity between the self-adaptive active metal powder cover 301 and the double-layer energetic she...

Embodiment 2

[0126] The structure of each module in this embodiment is the same as that in Embodiment 1.

[0127] An oil well is taken as an example below to describe the application of this embodiment in detail.

[0128] A certain oil well has a depth of 3400m, oil and gas layer thickness of 50m, and reservoir location: 2980.2-3030.2m, belonging to tight gas sandstone. Since this well section is developed with low porosity and permeability, the drilling mud pollutes the near-wellbore area during the drilling process. Through detailed analysis and demonstration by the construction department, it is believed that conventional perforation methods cannot effectively open the polluted reservoir. Supporting equipment and on-site construction conditions are limited, and new perforation efficiency enhancement technology needs to be adopted. Through technical comparison and on-site construction period requirements, the super-combustion self-adaptive perforation efficiency enhancement technology is...

Embodiment 3

[0138] The structure of each module in this embodiment is the same as that in Embodiment 1.

[0139] The application of this embodiment will be described in detail below by taking a water injection well of an oil factory as an example.

[0140] The water injection well of an oil factory has a depth of 1400m and a water injection interval of 650m to 680m, which is a transfer injection well. Since the well could not be effectively injected before, it is still in a shutdown state.

[0141] Considering the complex geological structure and tight formation in the area where the oil well is located, the super-combustion wave pulse perforation technology scheme was optimally designed, and the material selection was optimized through the system. The relevant design components and mass percentages of Example 3 are as follows:

[0142] The components and mass percentages of the self-adaptive active metal charge 301 of the scram self-adaptive energy release charge 3 are: copper 25%; tungst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com