Isobaric fuel injection pump of high-speed machine

A technology of fuel injection pump and high-speed engine, which is applied in the field of marine engines, can solve the problems of large space occupied by the ring gear and rack mechanism, large mass of moving parts, and high manufacturing cost, and achieve the effect of small moving mass, low processing difficulty, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

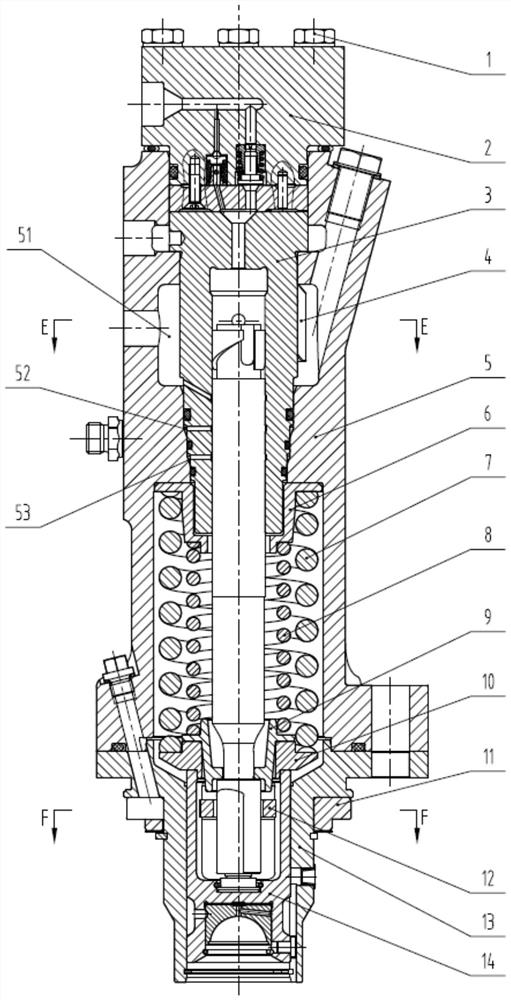

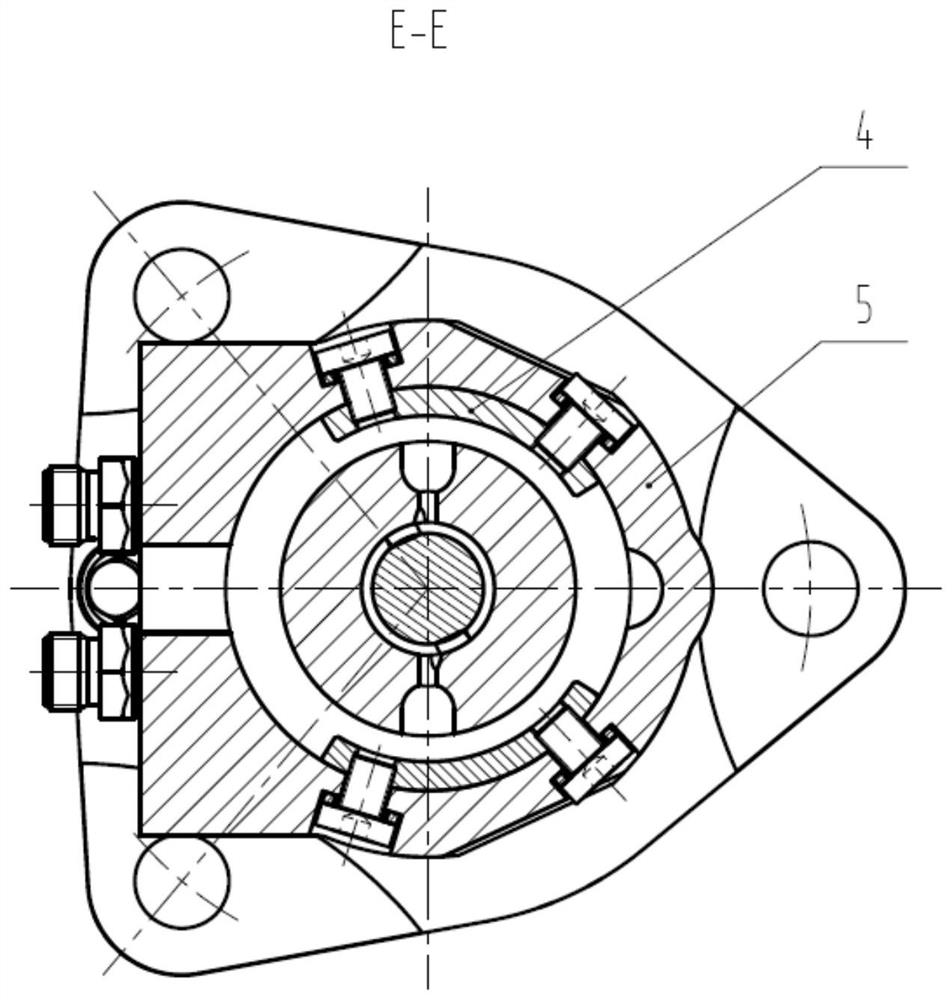

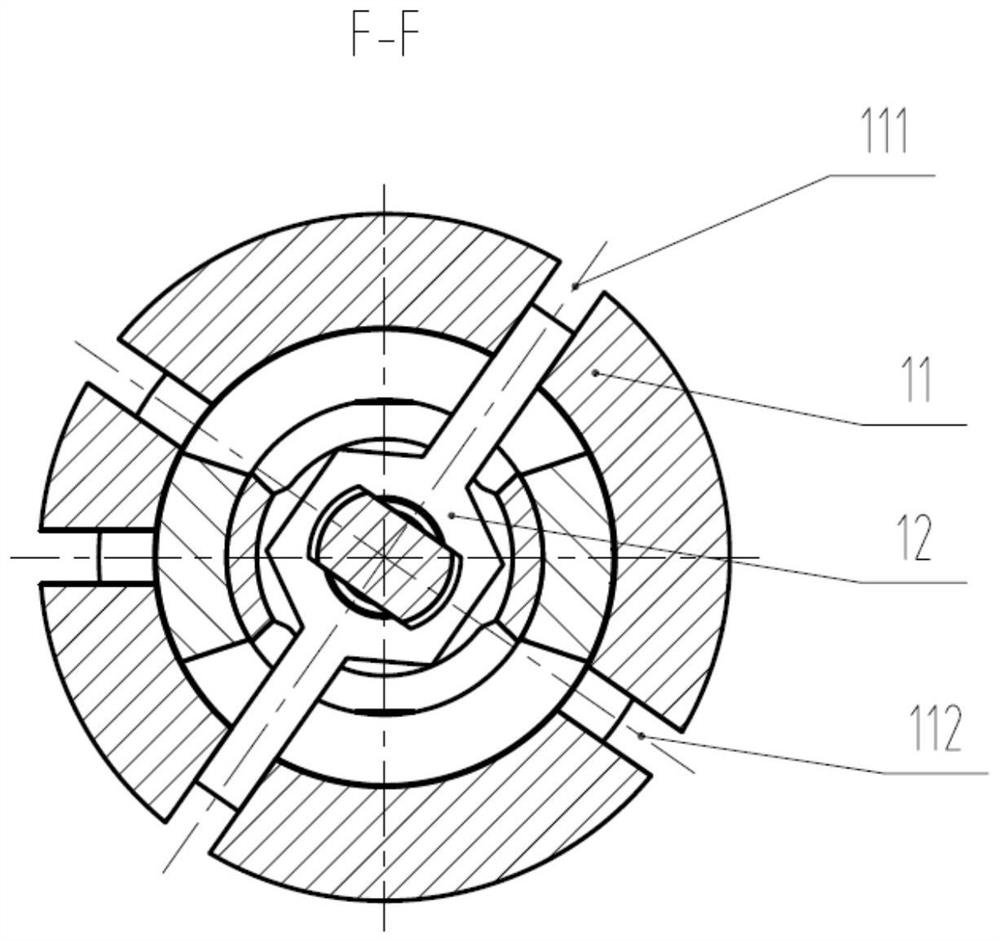

[0044] refer to Figure 1 to Figure 6 , the embodiment of the present invention provides a new type of constant pressure fuel injection pump for high-speed machines, which specifically includes an equal pressure oil outlet valve assembly 2, a plunger coupling 3, and a pump body 5, which are assembled in the middle hole of the pump body 5 from top to bottom. Big spring 7 , small spring 8 , lower spring seat 9 , lower spring plate 10 , lower body 13 , control sleeve 11 assembled on lower body 13 , lever 12 and guide cylinder assembly 14 assembled in the middle hole of lower body 3 .

[0045] Such as figure 1 As mentioned above, the plunger coupler 3 is suspended and installed in the middle hole of the pump body 5, and the equal pressure oil outlet valve assembly 2 is installed on the upper end of the plunger coupler 3, and is locked with the pump body 5 by six powerful screws 1, and the pump body 5 A low-pressure fuel chamber 51, a lubricating oil return chamber 52, and a lubri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com