Composite material cable conduit

A technology of cable conduit and composite materials, applied in shielding materials, rigid plastic containers with coated shielding materials, electrical components, etc., can solve problems such as signal leakage, permanent damage, signal, human and object interference, etc., and achieve good shielding Performance, good shielding effect, effective effect of electromagnetic radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Using 12K carbon fiber as a reinforcing material, a polypropylene composite cable conduit with a diameter of 200mm and shielding function was prepared. The specific preparation process is as follows:

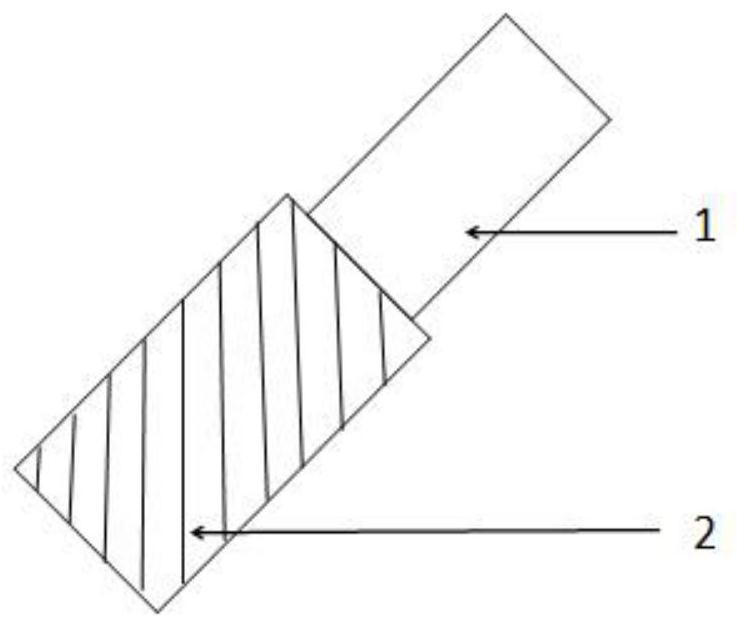

[0024] A composite material cable conduit, comprising a high melting point polypropylene inner tube 1 and a composite material shielding layer 2 coated on the surface of the inner tube;

[0025] The shielding layer 2 is a carbon fiber reinforced modified polypropylene layer;

[0026] The modified polypropylene is low-melting polypropylene for shielding with conductive filler added.

[0027] The preparation steps are:

[0028] Step (1): Put polypropylene with a melting point of 165°C and 800-mesh silver powder into a high-speed mixer for thorough mixing, and then extrude to granulate;

[0029] Step (2): put polypropylene with a melting point of 185°C into a twin-screw extruder for melt extrusion, traction, and shaping to prepare a high-melting-point polypropylene inner t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com