Production method of double-station double-sided stainless steel composite band

A technology of stainless steel strips and production methods, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve problems such as poor anti-interference ability, easy corrosion, complicated production and processing processes, etc., and meet the requirements of reducing the use environment , High heat-sealing bonding performance, low initial bonding temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

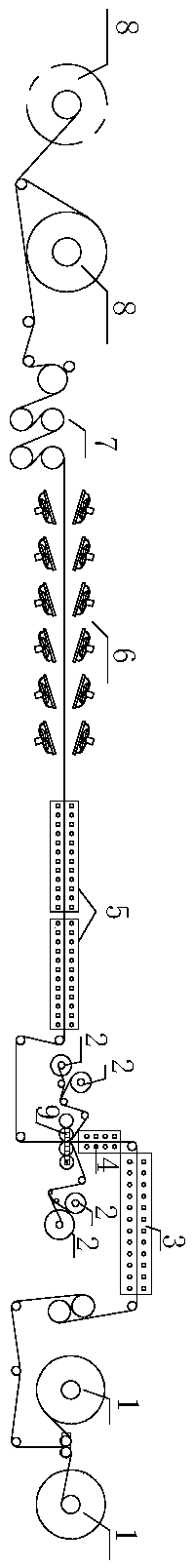

Image

Examples

Embodiment 1

[0030] Embodiment one: the present invention is a kind of production method of double-sided stainless steel composite strip, adopts following processing steps:

[0031] 1. Select double-sided stainless steel composite belt material:

[0032] Raw material stainless steel strip: use 301 stainless steel strip, thickness 0.10mm, width 500mm; main standards: tensile strength: 500-700Mpa, elongation at break ≥ 30%, thickness tolerance ± 8%; use PE polyethylene plastic produced by EAA Dupont Film, thickness 0.05mm, width 500mm main standards: tensile strength ≥ 16MPa, elongation at break (longitudinal) ≥ 250%, elongation at break (transverse) ≥ 400%, heat seal strength ≥ 18.5N / cm, peel strength ≥ 6.3N / cm, layered: not layered;

[0033] 2. Unwinding process

[0034] The 301 stainless steel tape roll frame is attached to the stainless steel unwinding device (1), and the stainless steel unwinding device (1) is connected to the magnetic powder brake, which uses magnetic powder to tran...

Embodiment 2

[0051] Embodiment two: the present invention is a kind of production method of double-sided stainless steel composite strip, adopts following processing steps:

[0052] 1. Select double-sided stainless steel composite belt material:

[0053] Raw material stainless steel strip: 301 stainless steel strip, thickness 0.13mm, width 500mm; main standards: tensile strength: 500-700Mpa, elongation at break ≥ 30%, thickness tolerance ± 8%; film selection of PE polyethylene produced by EAA DuPont Plastic film, PE polyethylene plastic film thickness 0.05mm, width 500mm main standards: tensile strength ≥ 16MPa, elongation at break (longitudinal) ≥ 250%, elongation at break (transverse) ≥ 400%, heat seal strength ≥ 18.5N / cm , peel strength ≥ 6.3N / cm, delamination: no delamination;

[0054] 2. Unwinding process

[0055] The 301 stainless steel tape roll frame is attached to the stainless steel unwinding device (1), and the stainless steel unwinding device (1) is connected to the magnetic po...

Embodiment 3

[0072] Embodiment three: the present invention is a kind of production method of double-sided stainless steel composite strip, adopts following processing steps:

[0073] 1. Select double-sided stainless steel composite belt material

[0074] Raw material stainless steel strip: use 301 stainless steel strip, thickness 0.15mm, width 500mm; main standards: tensile strength: 52-750Mpa, elongation at break ≥ 30%, thickness tolerance ± 8%; PE plastic film thickness 0.05mm, width 500mm main standards: tensile strength ≥ 16MPa, elongation at break (longitudinal) ≥ 250%, elongation at break (transverse) ≥ 400%, heat sealing strength ≥ 18.5N / cm, peel strength ≥ 6.3N / cm, delamination: no layered;

[0075] 2. Unwinding process

[0076] The 301 stainless steel tape roll frame is attached to the stainless steel unwinding device (1), and the stainless steel unwinding device (1) is connected to the magnetic powder brake, which uses magnetic powder to transmit torque;

[0077] The PE polye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com