High-strength spring guide base for hydraulic system powder metallurgy and production process thereof

A powder metallurgy and hydraulic system technology, applied in the field of powder metallurgy, can solve the problems of low processing efficiency, low utilization rate of raw materials, poor surface condition of workpieces, etc., to improve wear resistance and corrosion resistance, improve product surface condition, optimize The effect of product design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

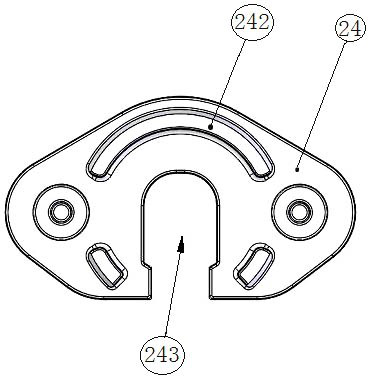

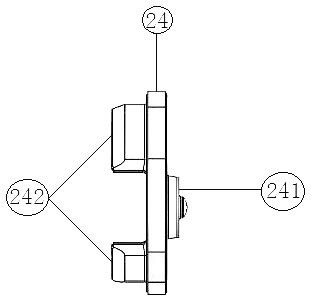

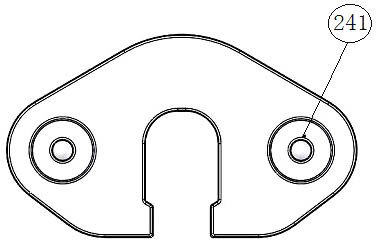

[0027] refer to figure 1 As shown, a hydraulic system powder metallurgy high-strength spring guide seat includes a flange 24, and a pair of circular bosses 241 are arranged on one end surface of the flange 24, which are used to fix the position of the spring and define For the center distance between the two springs, several sections of C-shaped steps 242 are provided on one end surface of the flange 24 for support.

[0028] The center of the flange 24 is provided with a forming groove 243 extending to the lower end to form an opening, and the circular protrusions 241 are symmetrically arranged on both sides of the forming groove 243 .

[0029] The C-shaped step 242 has three sections, one of which is located above the forming groove 243 , and the other two sections are located below the circular boss 241 and symmetrically arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com