Bismuth ferrite-based ceramic with excellent magnetoelectric properties and preparation method thereof

A bismuth ferrite-based ceramic and bismuth ferrite-based technology, applied in the field of dielectric materials, can solve the problems of weak magnetoelectric properties, poor macroscopic magnetic properties, etc., and achieve the effects of improved magnetic properties, excellent magnetic properties, and improved performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

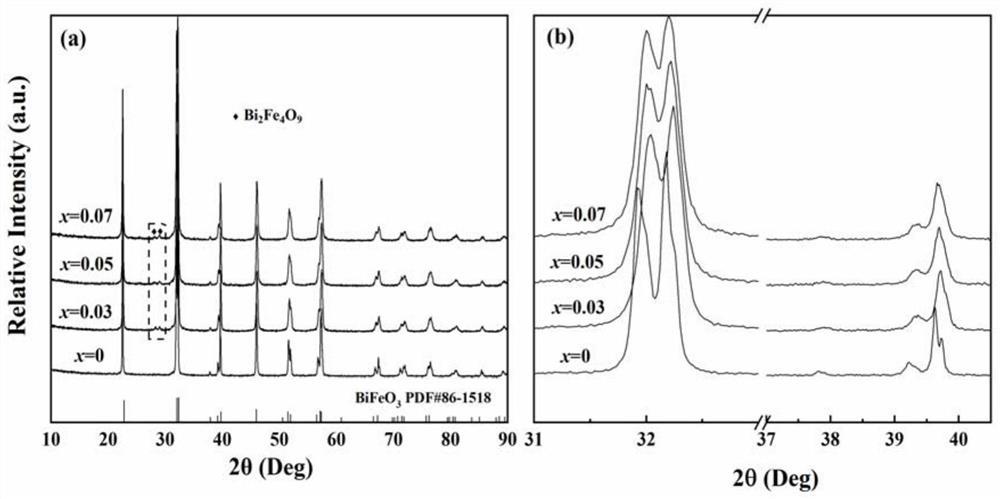

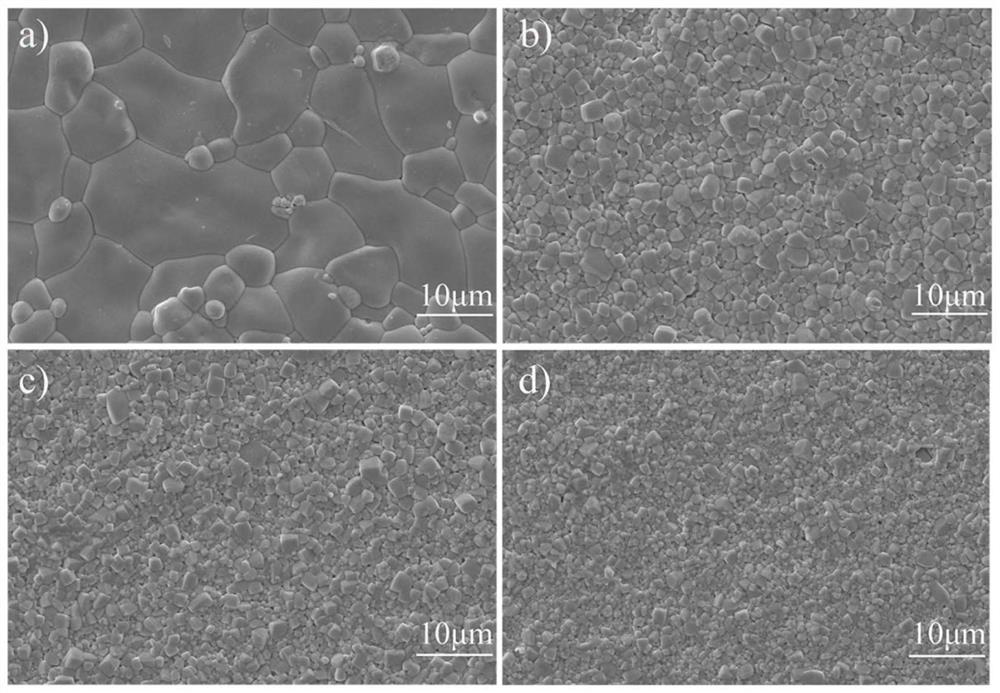

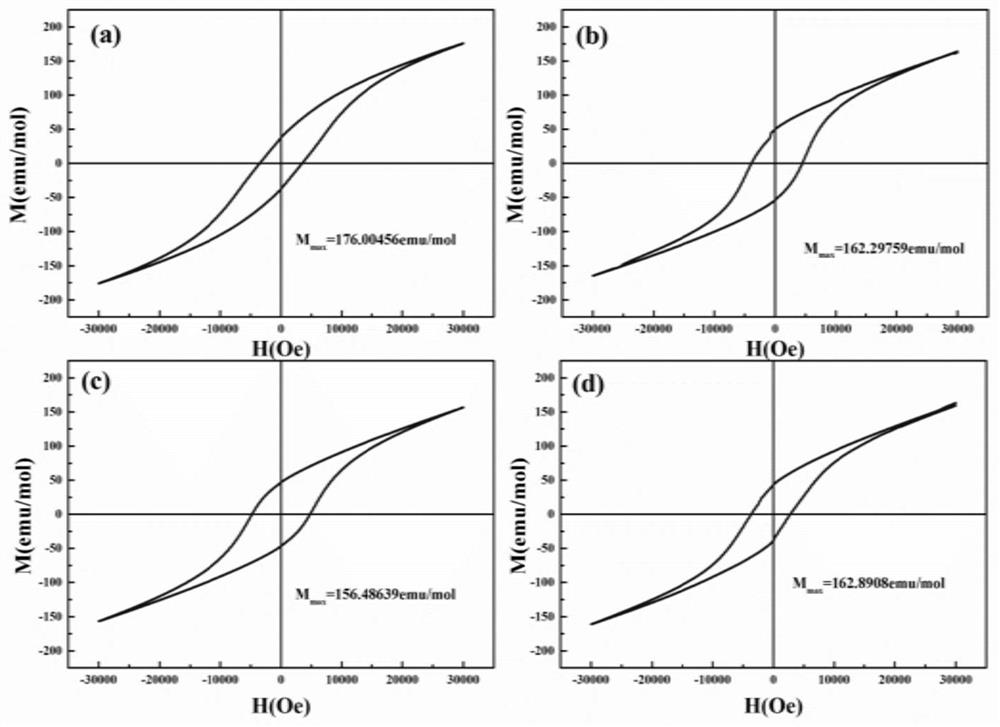

[0055] A bismuth ferrite-based ceramic with excellent magnetic properties in this embodiment has a chemical composition of:

[0056] 0.84BiFeO 3 -0.06SmFeO 3 -0.1CaTiO 3 .

[0057] The concrete preparation steps of this ceramic material are as follows:

[0058] Ingredients: Put the raw materials in an oven at 80°C for 24 hours to remove any moisture that may exist. 3 -0.06SmFeO 3 -0.1CaTiO 3The stoichiometric ratio of various elements in the formula weighs high-purity (greater than 99%) Bi 2 o 3 , Fe 2 o 3 、Sm 2 o 3 , CaCO 3 、TiO 2 .

[0059] One-time ball milling: Put the raw materials weighed according to the stoichiometric ratio into a nylon tank, put zirconia balls as the ball milling medium, add deionized water, and put them on the ball mill for ball milling to make them evenly mixed. The ball milling time is 24 hours and the speed is 200r / min.

[0060] Drying and sieving: Pour the above slurry into a drying dish, put it in an oven, and dry it for 48 hour...

Embodiment 2

[0070] A bismuth ferrite-based ceramic with excellent magnetic properties in this embodiment has a chemical composition of:

[0071] 0.81BiFeO 3 -0.06SmFeO 3 -0.1CaTiO 3 -0.03BiMnO 3 .

[0072] Concrete preparation steps are as follows:

[0073] Ingredients: Put the raw materials in an oven at 80°C for 24 hours to remove any moisture that may exist. 3 -0.06SmFeO 3 -0.1CaTiO 3 -0.03BiMnO 3 The stoichiometric ratio of various elements in the formula weighs high-purity (greater than 99%) Bi 2 o 3 , Fe 2 o 3 、Sm 2 o 3 , CaCO 3 、TiO 2 , Mn 2 o 3 .

[0074] One-time ball milling: Put the raw materials weighed according to the stoichiometric ratio into a nylon tank, put zirconia balls as the ball milling medium, add deionized water, and put them on the ball mill for ball milling to make them evenly mixed. The ball milling time is 24 hours and the speed is 200r / min.

[0075] Drying and sieving: Pour the above slurry into a drying dish, put it in an oven, and dry i...

Embodiment 3

[0085] In this embodiment, a bismuth ferrite-based ceramic with excellent magnetic properties has a chemical composition of

[0086] 0.79BiFeO 3 -0.06SmFeO 3 -0.1CaTiO 3 -0.05BiMnO 3 .

[0087] Concrete preparation steps are as follows:

[0088] Ingredients: Put the raw materials in an oven at 80°C and dry them for 24 hours to remove any moisture that may exist. 3 -0.06SmFeO 3 -0.1CaTiO 3 -0.05BiMnO 3 The stoichiometric ratio of various elements in the high-purity Bi 2 o 3 , Fe 2 o 3 、Sm 2 o 3 , CaCO 3 、TiO 2 , Mn 2 o 3 .

[0089] One-time ball milling: Put the raw materials weighed according to the stoichiometric ratio into a nylon tank, put zirconia balls as the ball milling medium, add deionized water, and put them on the ball mill for ball milling to make them evenly mixed. The ball milling time is 24 hours and the speed is 200r / min.

[0090] Drying and sieving: Pour the above slurry into a drying dish, put it in an oven, and dry it for 48 hours. After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com