Method for inhibiting engine oil emulsification of hybrid electric vehicle

A hybrid vehicle, oil technology, applied in the direction of engine lubrication, engine components, machines/engines, etc., can solve problems such as the decline of oil lubrication performance, the reduction of engine reliability and life, the decline of fuel economy and power performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

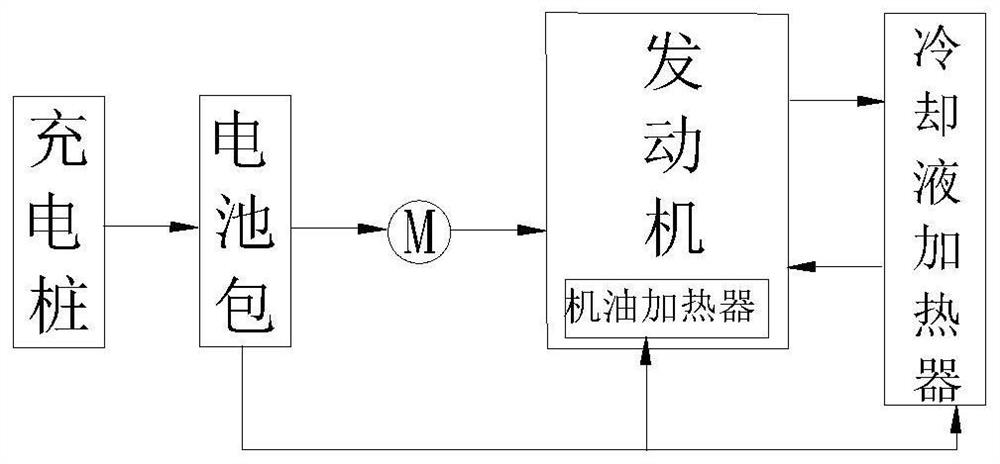

Image

Examples

Embodiment Construction

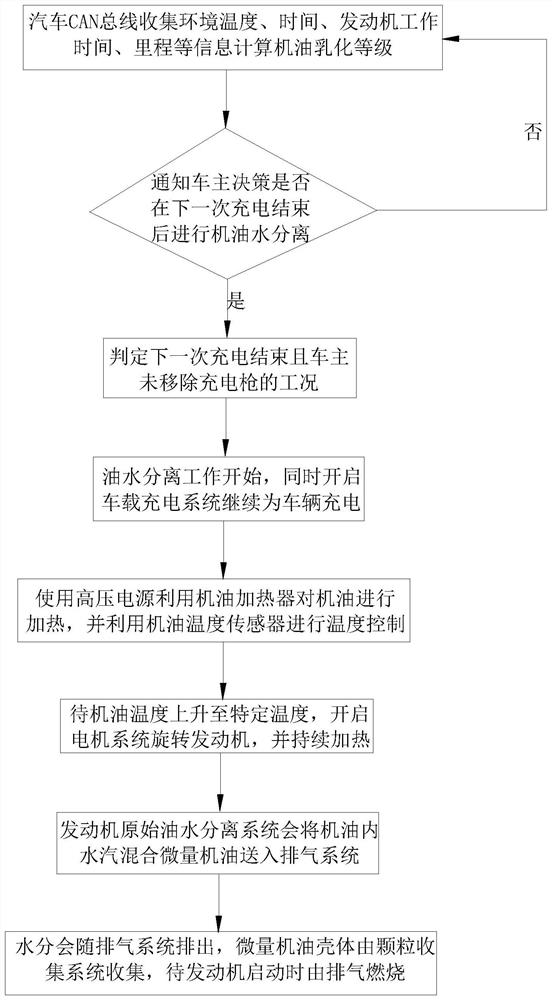

[0011] A method for inhibiting the emulsification of hybrid vehicle engine oil, comprising the following steps:

[0012] A) The car CAN bus collects information such as ambient temperature, time, engine working time, mileage and other information to calculate the oil emulsification level;

[0013] B) When the oil emulsification level reaches the limit value, notify the owner to decide whether to carry out the oil-water separation work after the next charge;

[0014] C) When the car owner decides to carry out the oil-water separation work, the car CAN bus capture charging ends and the car owner does not remove the charging gun, the oil-water separation work starts, and the on-board charging system is turned on at the same time to continue charging the vehicle.

[0015] Use the CAN bus information of the car to capture the working condition of the end of the car charging and the car owner has not removed the charging gun, combined with the time (preferably in the early morning, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com