Drying device for preserved fruit processing

A drying device and preserved fruit technology, applied in heating devices, drying, drying machines, etc., can solve the problems of increasing labor costs, polluting preserved fruits, etc., reduce heat loss and waste, prolong time, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

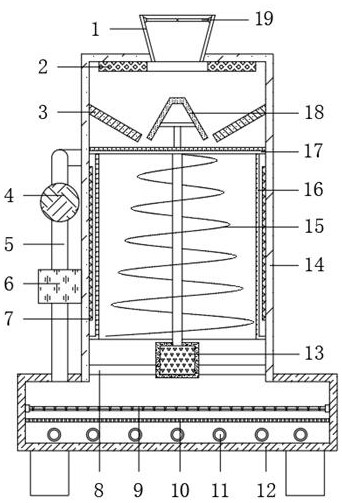

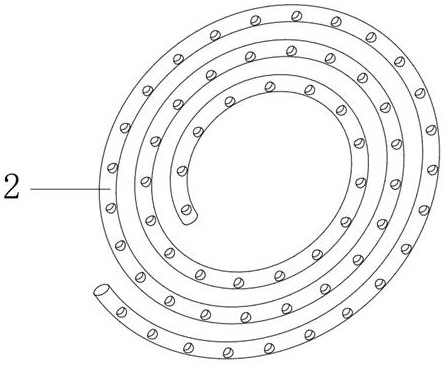

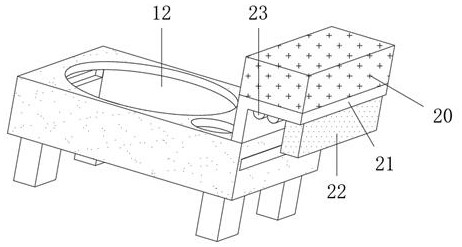

[0028] refer to Figure 1-6 , a drying device for preserved fruit processing, comprising a discharge box 12, a drying cylinder 14 is fixedly installed on the top of the discharge box 12, and a rectangular bucket 1 is fixedly installed on the top of the drying cylinder 14, and one end of the outer wall of the top of the discharge box 12 is inserted A recovery pipe 5 is connected, and the recovery pipe 5 is fixedly installed with a purification cylinder 6 and a circulation pump 4 from bottom to top, and the inside of the drying cylinder 14 is fixedly installed with a mosquito coil outlet pipe 2, a vibrating material plate 3, The tripod 17, the electric heating network 7, the pentagonal frame 8, and the middle of the top of the tripod 17 are fixedly installed with a limited bucket 18 through a T-shaped column, the outer side of the electric heating network 7 is fixedly installed with the first heat conduction network 16, and the middle of the pentagonal frame 8 is inlaid with a se...

Embodiment 2

[0038] refer to Figure 7 , a drying device for preserved fruit processing, further, a U-shaped plate 27 is fixedly installed on the upper end of the outer wall at one end of the discharge box 12, and the lowest part of the U-shaped plate 27 is equal to the rectangular opening, and the upper end of the outer wall on one side of the U-shaped plate 27 is fixedly installed There is a second motor 28, and a push roller 29 is fixedly installed at the output end of the second motor 28.

[0039] Working principle: The worker lays the feeding screen 9 on the surface of the U-shaped board 27 in sequence, and the push roller 29 rotates with the second motor 28, so that the feeding screen 9 moves forward at a uniform speed, so that the whole device automatically comes out. materials, saving manpower and material resources.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com