Osmanthus fragrans scented oolong tea and preparation method thereof

A technology of oolong tea and sweet-scented osmanthus, which is applied to tea, tea spices, tea treatment before extraction, etc., to achieve the effect of refreshing taste, long aftertaste, improving quality and added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

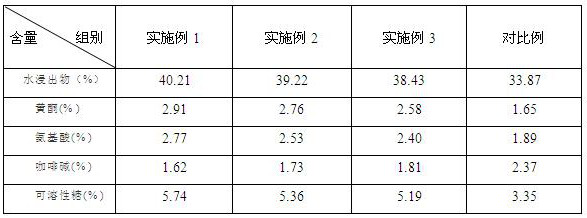

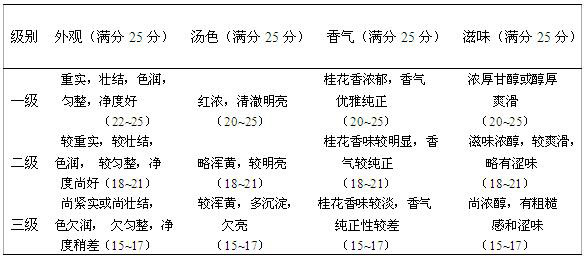

Examples

Embodiment 1

[0029] A kind of sweet-scented osmanthus scenting system oolong tea, the percentage by weight of each component in the raw material formula of described sweet-scented osmanthus scenting system oolong tea is: oolong tea green 55%, raspberry leaf 20%, sweet-scented osmanthus 25%;

[0030] Wherein, the preparation method of described osmanthus scenting oolong tea comprises the following steps:

[0031] (1) Picking: picking fresh tea leaves with 2~3 leaves in a bud, picking fresh raspberry bud leaves;

[0032] (2) Sun drying: spread the picked fresh tea leaves and raspberry leaves on the bamboo sieve, and let them dry naturally for 30 minutes at a temperature of 20°C;

[0033] (3) Greening: Shake the withered tea leaves at a slow speed for 1 minute at an indoor temperature of 20°C and a humidity of 70%, spread them on a bamboo sieve with a leaf thickness of 6 cm, let it stand for 2 hours, continue shaking at a slow speed for 3 minutes, and spread Spread on a bamboo sieve with a l...

Embodiment 2

[0041] A kind of sweet-scented osmanthus scenting system oolong tea, the percentage by weight of each component in the raw material formula of described sweet-scented osmanthus scenting system oolong tea is: oolong tea green 65%, raspberry leaf 15%, sweet-scented osmanthus 20%;

[0042] Wherein, the preparation method of described osmanthus scenting oolong tea comprises the following steps:

[0043] (1) Picking: picking fresh tea leaves with 2~3 leaves in a bud, picking fresh raspberry bud leaves;

[0044] (2) Sun drying: spread the picked fresh tea leaves and raspberry leaves on the bamboo sieve, and let them dry naturally for 25 minutes at a temperature of 22°C;

[0045] (3) Greening: Shake the withered tea leaves at a slow speed for 1.5 minutes at an indoor temperature of 22°C and a humidity of 75%, spread them on a bamboo sieve with a leaf thickness of 7 cm, let them stand for 2.5 hours, and continue shaking at a slow speed for 4 minutes , spread on a bamboo sieve with a le...

Embodiment 3

[0053] A kind of sweet-scented osmanthus scenting system oolong tea, the percentage by weight of each component in the raw material formula of described sweet-scented osmanthus scenting system oolong tea is: oolong tea green 75%, raspberry leaf 10%, sweet-scented osmanthus 15%;

[0054] Wherein, the preparation method of described osmanthus scenting oolong tea comprises the following steps:

[0055] (1) Picking: picking fresh tea leaves with 2~3 leaves in a bud, picking fresh raspberry bud leaves;

[0056] (2) Sun drying: spread the picked fresh tea leaves and raspberry leaves on the bamboo sieve, and let them dry naturally for 30 minutes at a temperature of 25°C;

[0057] (3) Greening: Shake the withered tea leaves at a slow speed for 2 minutes at an indoor temperature of 25°C and a humidity of 80%, spread them on a bamboo sieve with a leaf thickness of 8 cm, let them stand for 3 hours, continue to shake them at a slow speed for 5 minutes, and spread Spread on a bamboo sieve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com