Preparation method of whole brown rice aged fermented steamed buns

A technology of brown rice and steamed buns, which is applied in the direction of food ingredients as taste improvers, food ingredients, food science, etc., to achieve the effect of prolonging the storage period, fine powder quality, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

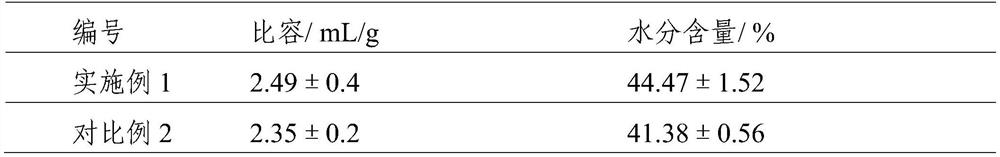

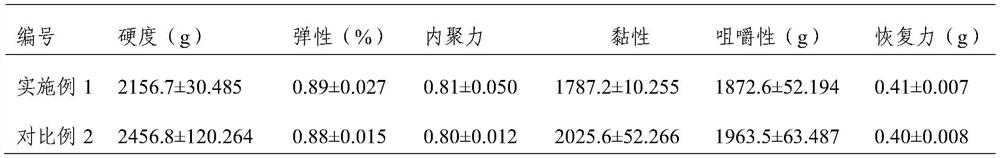

Examples

Embodiment 1

[0046] A kind of preparation method of whole brown rice aged fermented steamed bread comprises the steps:

[0047] S1, brown rice is made whole brown rice powder;

[0048] S11. Preliminary screening and cleaning of brown rice: the japonica rice and glutinous rice newly harvested in the year are firstly husked and separated from paddy, and then color sorted to remove insect grains, diseased grains, immature grains, and heterochromatic grains, and finally obtain high-quality grains Brown rice; then rinse the brown rice with clean water 2-3 times to remove surface ash;

[0049] S12, soaking of brown rice: the brown japonica rice after step S11 initial clearing, adopt cellulase-glutamine transaminase solution (wherein, cellulase concentration is 0.5%, and glutamine transaminase concentration is 1.5%) at 30 ℃ Soak down for 2h to make its moisture reach 20%; with the brown glutinous rice after step S11 primary clearing, use cellulase-transglutaminase solution (wherein, the cellulas...

Embodiment 2

[0064] A kind of preparation method of whole brown rice aged fermented steamed bread comprises the steps:

[0065] S1, brown rice is made whole brown rice powder;

[0066] S11. Preliminary screening and cleaning of brown rice: the japonica rice and glutinous rice newly harvested in the year are firstly husked and separated from paddy, and then color sorted to remove insect grains, diseased grains, immature grains, and heterochromatic grains, and finally obtain high-quality grains Brown rice; then rinse the brown rice with clean water 2-3 times to remove surface ash;

[0067] S12, soaking of brown rice: the brown japonica rice after step S11 initial clearing, adopt cellulase-transglutaminase solution (wherein, cellulase concentration is 1%, and glutamine transaminase concentration is 1%) at 35 ℃ Soak it down for 2h to make its moisture reach 22%; with the brown glutinous rice after step S11 primary clearing, use cellulase-transglutaminase solution (wherein, the cellulase conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com