Environment-friendly edge tool box with antifouling coating

An antifouling coating and sharps box technology, which is applied in the direction of devices introduced into the body, hypodermic injection devices, medical science, etc., can solve the problems of affecting the burning rate of sharps boxes, incomplete combustion of sharps boxes, and increasing operation intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

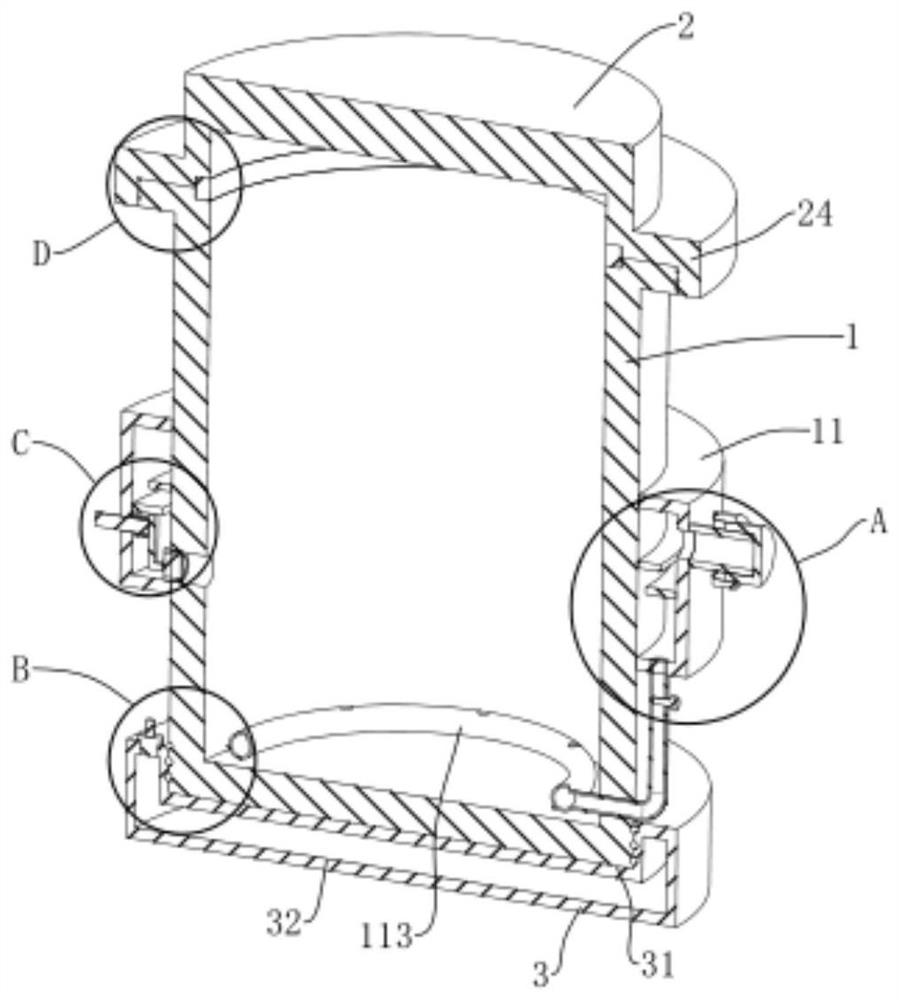

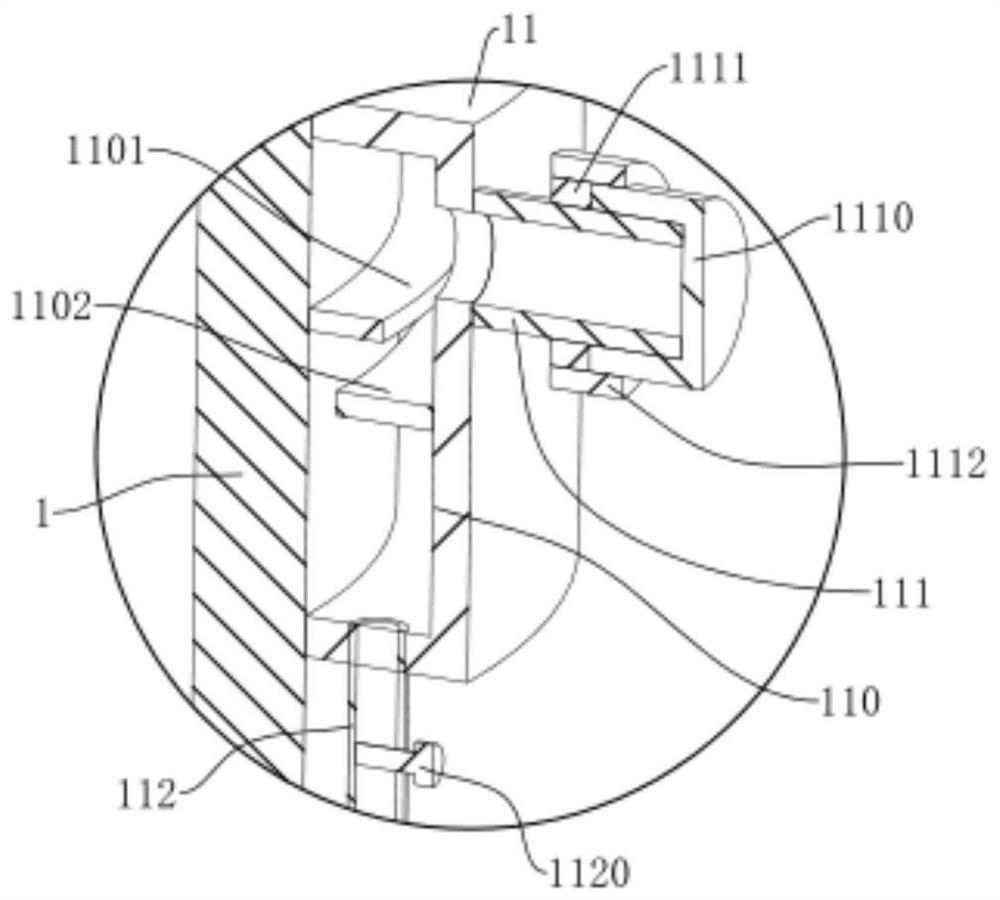

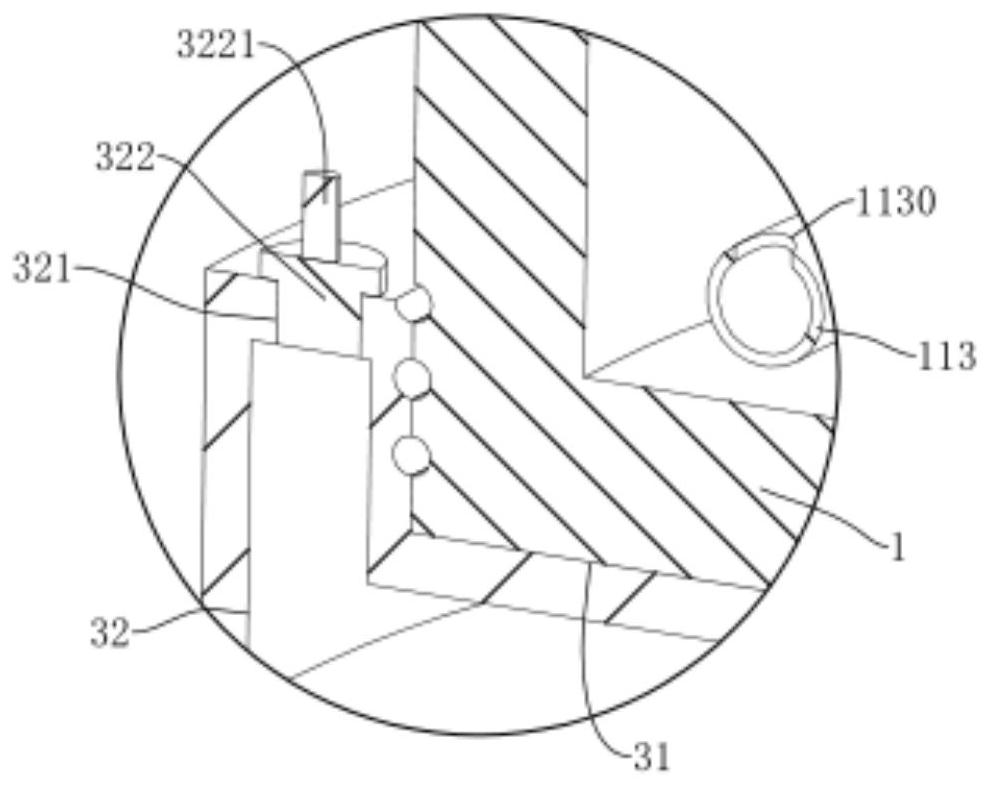

[0045] refer to figure 1 , figure 2 and image 3 , an environmentally friendly sharps box with an antifouling coating, including a box body 1 and a box cover 2, wherein the box body 1 has a protruding cylinder part 11 integrally formed with the box body 1, and inside the protruding cylinder part 11 A fuel tank 110 for placing fuel is provided. In order to facilitate filling fuel into the fuel tank 110 in the protruding cylinder part 11, there is a feeding pipe 111 communicated with the fuel tank 110 on the protruding cylinder part 11, wherein the feeding pipe 111 is a plastic pipe, and the protruding tube part 11 has a first split ring 1101 and a second split ring 1102 integrally formed with the protruding tube part 11 inside the fuel tank 110, and there is also a ring at the bottom end of the protruding tube part 11 The plastic elbow 112 that communicates with the fuel tank 110, wherein the end of the plastic elbow 112 away from the protruding cylinder 11 passes through th...

Embodiment 2

[0053] The difference from Example 1 is that the surface of the lid 2 is coated with an anti-fouling coating. Since the lid 2 may come into contact with sharp objects, in order to prevent the lid 2 from becoming dirty, the surface of the lid 2 Coated with a layer of antifouling coating, wherein the antifouling coating is prepared by the following method:

[0054] Take the following components by weight as raw materials: 38 parts of polyethylene, 35 parts of polyvinyl chloride, 12 parts of dimethyl adipate, 8 parts of potassium oleate, 6 parts of ethyl acetate, 5 parts of hydroxyethylated fatty amine Parts, 6 parts of diphenyl ethyl ketone, 5 parts of diethoxy acetophenone ester, 5 parts of sodium benzoate;

[0055] S1. Refining: Mix polyethylene, polyvinyl chloride, dimethyl adipate, ethyl acetate, hydroxyethylated aliphatic amine and diethoxyacetophenone ester evenly, stir thoroughly at high speed, and place in a dense The refining machine was refined at 135°C for 30 minutes...

Embodiment 3

[0061] The difference from Example 2 is the preparation of the antifouling coating on the surface of the lid 2, wherein the preparation method of the antifouling coating is as follows:

[0062] Take the following raw materials of each component by weight for later use: 39 parts of polyethylene, 36 parts of polyvinyl chloride, 13 parts of dimethyl adipate, 9 parts of potassium oleate, 6 parts of ethyl acetate, 5 parts of hydroxyethylated fatty amine Parts, 6 parts of diphenyl ethyl ketone, 5 parts of diethoxy acetophenone ester, 5 parts of sodium benzoate;

[0063] S1. Refining: Mix polyethylene, polyvinyl chloride, dimethyl adipate, ethyl acetate, hydroxyethylated aliphatic amine and diethoxyacetophenone ester evenly, stir thoroughly at high speed, and place in a dense The refining machine was refined at 135°C for 30 minutes to obtain the first pre-preparation solution;

[0064] S2. Configure the second pre-preparation solution: mix and stir potassium oleate, diphenylethanone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com