A scr low temperature denitrification device

A low-temperature denitrification and catalyst technology, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of catalyst agglomeration deactivation, low catalytic efficiency, insufficient cooling effect of adsorption, etc., to prolong the reaction time , the effect of improving the catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

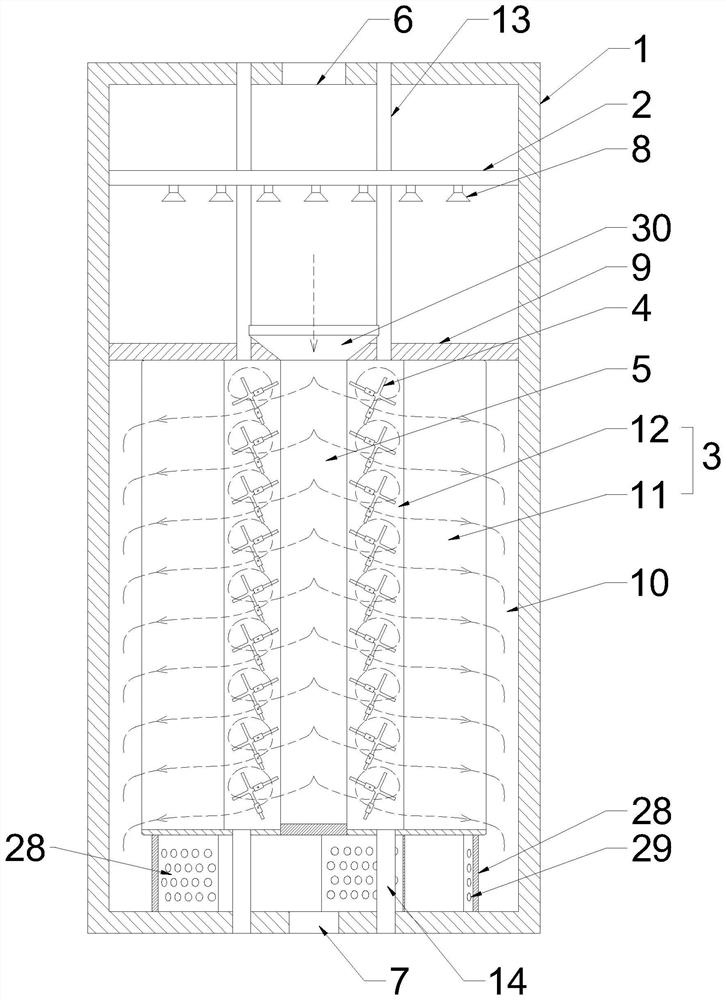

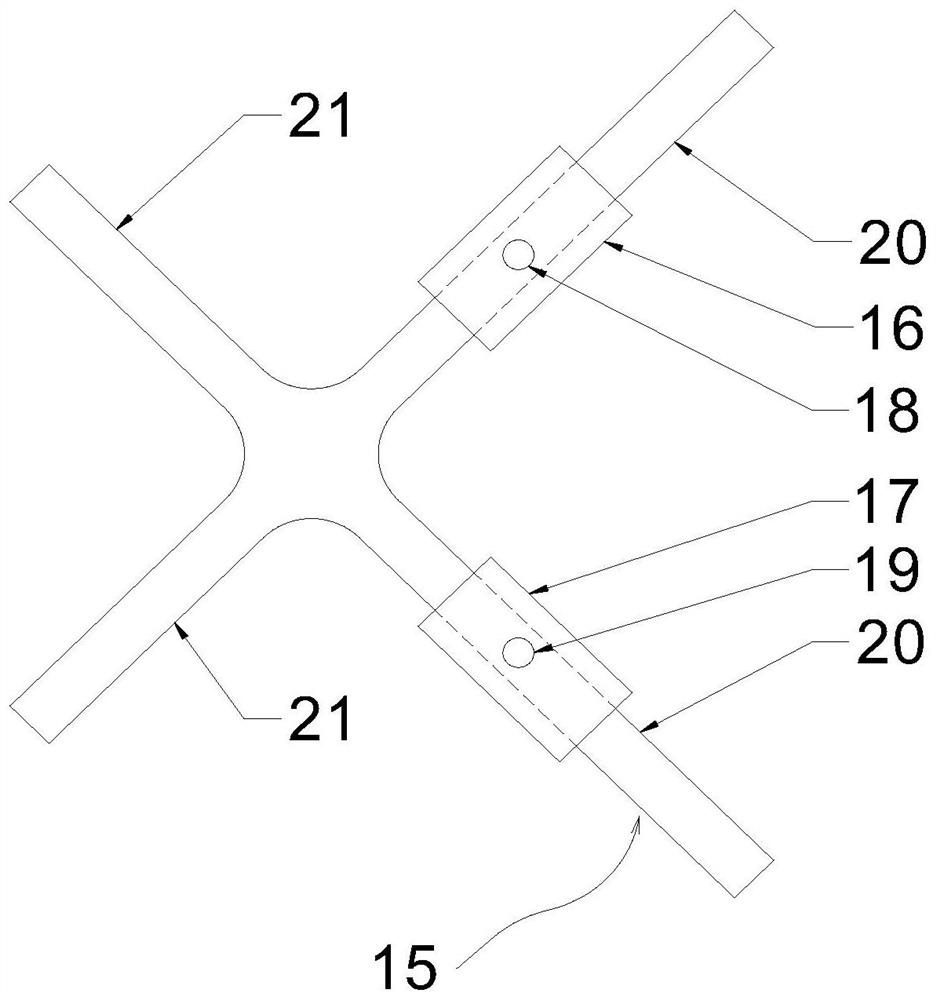

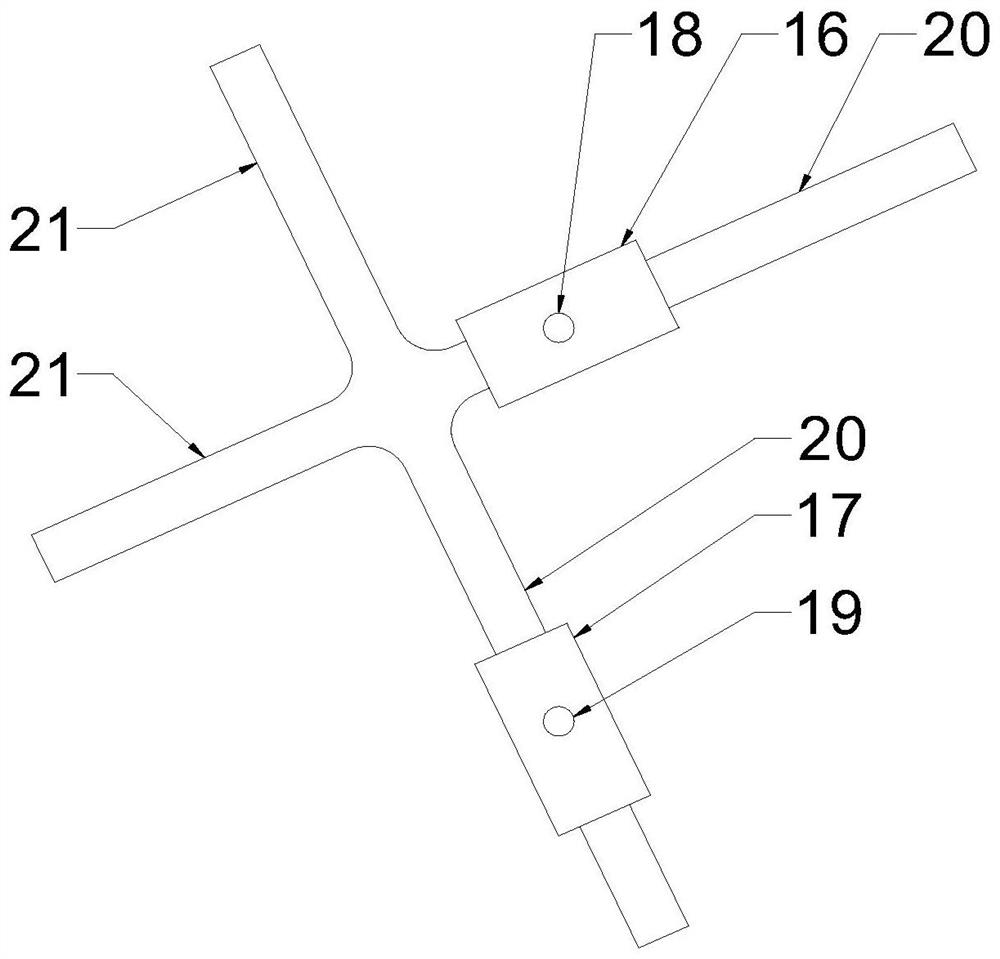

[0031] Such as Figure 1 to Figure 4 As shown, an SCR low-temperature denitrification device includes a reactor shell 1 , an ammonia injection grid 2 , a catalyst storage cylinder 3 , a turning member 4 and a reactor inner tube 5 . The top of the reactor shell 1 has a flue gas inlet 6 and the bottom has a flue gas outlet 7, and the desulfurized low-temperature flue gas (170-250° C.) is injected into the reactor shell 1 through the flue gas inlet 6 for denitrification.

[0032] A spray head 8 connected to the ammonia spray pipeline is installed on the ammonia spray grid 2. The spray head 8 sprays gasified ammonia gas to denitrify the flue gas containing NOX. The main products after the reaction are N2 and H2O. After the ammonium salt, dust and other pollutants are removed from the storage cylinder, the flue gas is discharged from the reactor shell 1 through the flue gas outlet 7 .

[0033] The catalyst storage cylinder 3 is fixed in the reactor shell 1 and is located below the...

Embodiment 2

[0049] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the base structure is different. The base of this embodiment includes a plurality of arc-shaped deflectors 32, and the deflectors 32 are arranged along a spiral trajectory, and the spiral trajectory is opposite to each other. There is an air intake gap 33 between the adjacent deflectors 32, and the airflow flowing out from the smoke overflow channel 10 passes through the air intake gap 33 and then quickly flows into the smoke outlet 7 along a spiral trajectory, and then is sucked into the chimney by the induced draft fan. Among them, several vent holes 29 are also provided on the outermost circle of deflector plates, so that the airflow in the smoke overflow channel 10 can quickly enter the spiral trajectory of the inner circle through the vent holes 29 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com