Feeding mechanism of heat exchanger bending machine and bending machine applying feeding mechanism

A technology of heat exchangers and feeding mechanisms, applied in heat exchange equipment, feeding devices, positioning devices, etc., can solve the problem of stuck workpieces to be bent, low operability of bending machines, and increased space occupied by bending machines And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

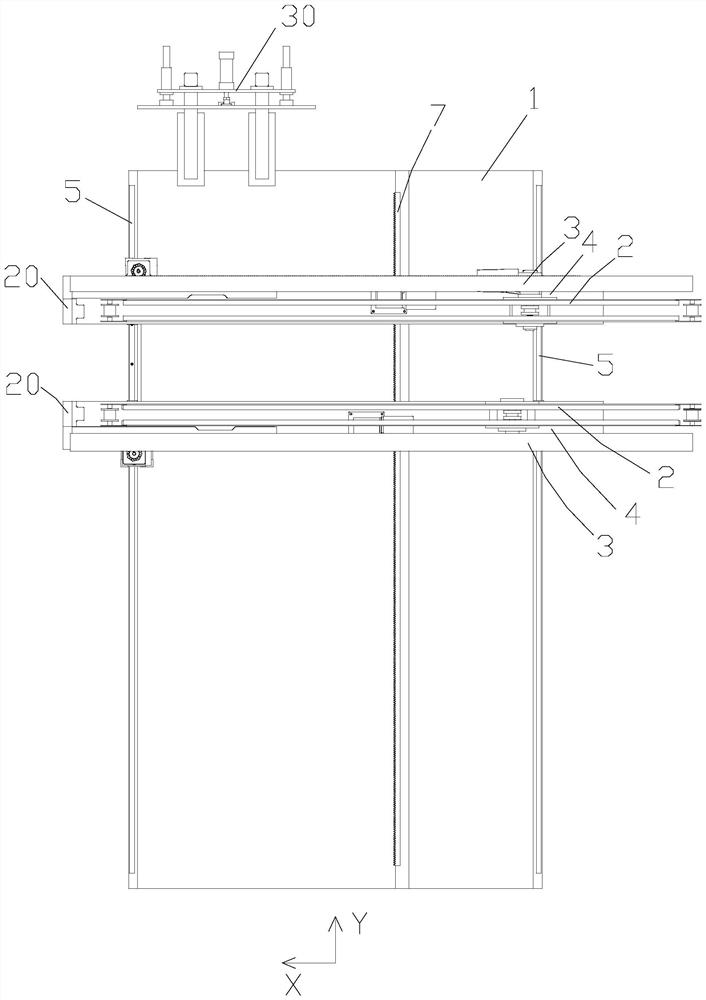

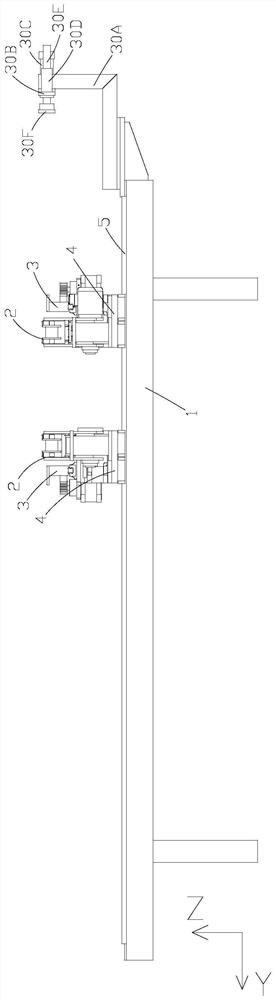

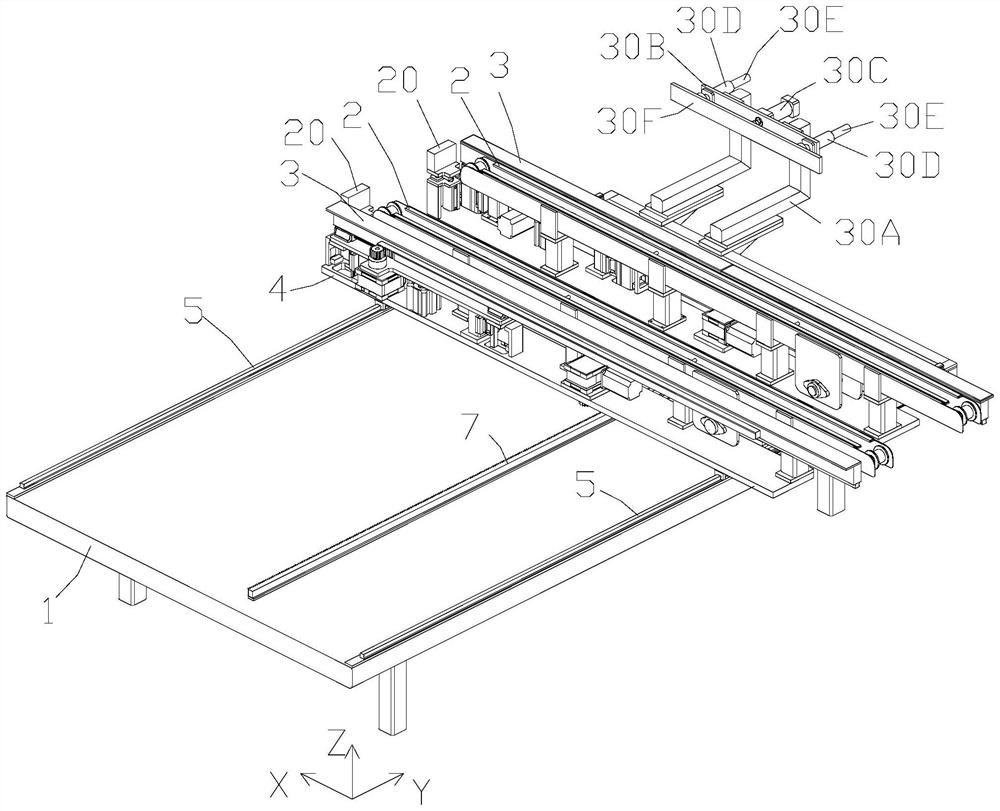

[0046] Such as Figure 1 to 8 As shown, the present embodiment provides a feeding mechanism of a heat exchanger bending machine, including an upper frame 1, and a conveying unit 10 for conveying a workpiece is provided, and the conveying unit 10 includes conveying. As part 2, the transport assembly 3 and the bottom plate 4, the conveying assembly 2 is used to carry and transport the workpiece; the transport assembly 3 is located on one side of the conveying assembly 2, and the transport assembly 3 can be along the X-axis and Z-axis direction of the upper housing 1. Move, the workpiece used to be folded on the transport assembly 2 and the workpiece is transported to the bending station or take out the workpiece of the bend on the bending station and transported to the delivery assembly 2; the bottom plate 4 The conveying path of the transport assembly 2 and the conveying path of the conveying assembly 2 and the transport assembly 2 are disposed parallel to each other along the conve...

Embodiment 2

[0056] The solution provided by the first example is applicable to the case where the distance between the workpiece transition interface and the bending station is not large, and the general improvement of the transport assembly 3 is improved, and the embodiment has made further improvements. Figure 9 with Figure 10 As shown in the present embodiment, the upper body includes an upper frame 1, which is provided in a carrier frame 8 on the upper frame 1 and a conveying unit 10 mounted on the carrier frame 8. A sheet lifting assembly 9 is provided between the object frame 8 and the upper frame 1, and the upper lifting assembly 9 drives the carrier frame 8 in the Z-axis direction of the upper housing frame 1, thereby driving the conveying unit 10. The rise or decrease, the conveying unit 10 is conveyed to the workpiece, wherein the conveying unit 10 in the present embodiment is consistent with the structure of the embodiment, which is no longer repeated, the carrier frame 8 is abov...

Embodiment 3

[0062] Such as Figure 11 with Figure 12 As shown, the present embodiment provides a bending machine, including the frame 100, a first bending mechanism 200, a second bending mechanism 300, and a second bending mechanism 300, and a second bending mechanism 300, which are provided on both sides of the workpiece can be completed on the frame 100. The follow-up mechanism 400 that can carry the workpiece on the rack 100, and the flow mechanism 400 is located between the first bending mechanism 200 and the second bending mechanism 300, further comprising the above-mentioned amounts of the first embodiment or the second embodiment. Institution 500, the upper body 500 is located on the frame 100, and the upper mechanism 500 delivers the workpiece to be bent to the bending station or takes the bending machine from the bending station. The feed mechanism, wherein the bending station is the position of the follow-up mechanism 400 of the bending machine, in the present embodiment, the follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com