Cleaning structure of drilling device and cleaning method

A technology of drilling device and exhaust hole, applied in boring/drilling, grinding drive device, drilling/drilling equipment, etc., can solve the problems of difficult handling, difficult cleaning of dust and residual burrs in holes, etc. To achieve the effect of thorough cleaning, good fit, and avoiding omissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

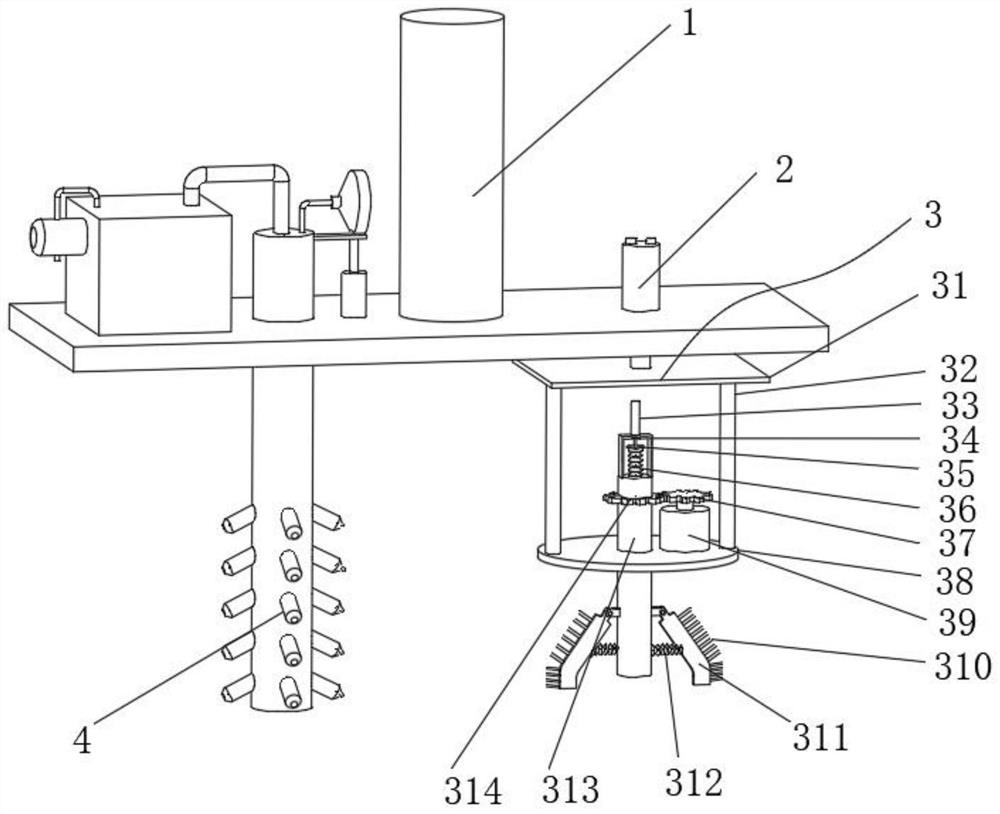

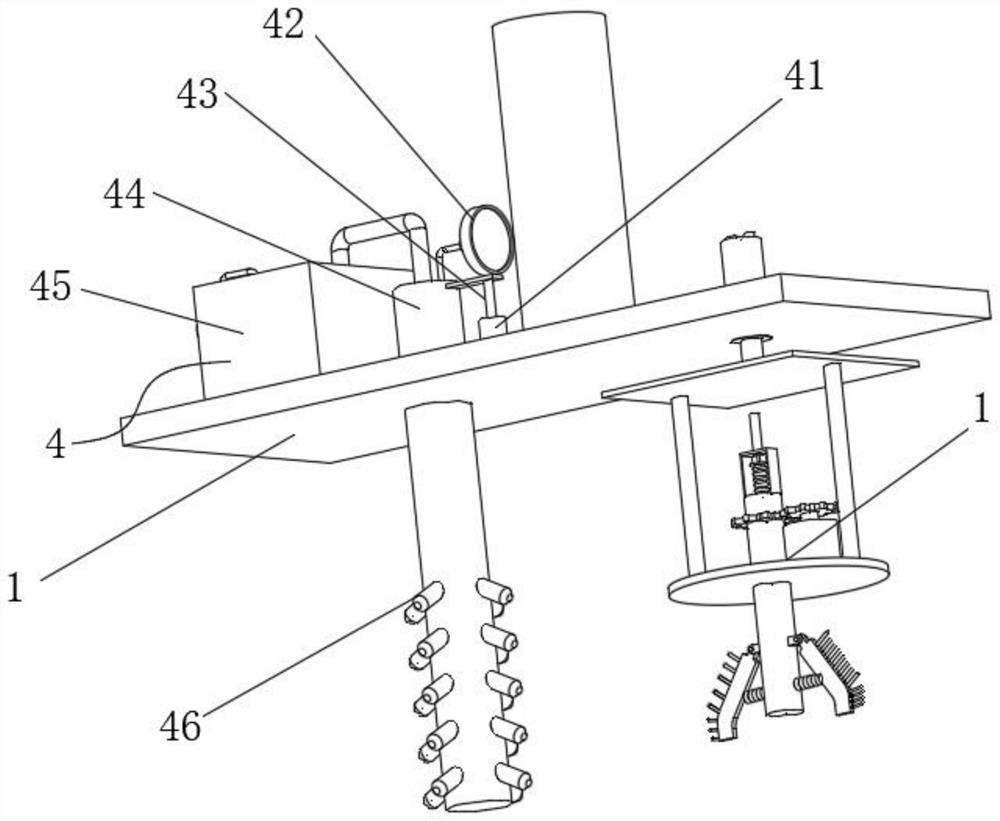

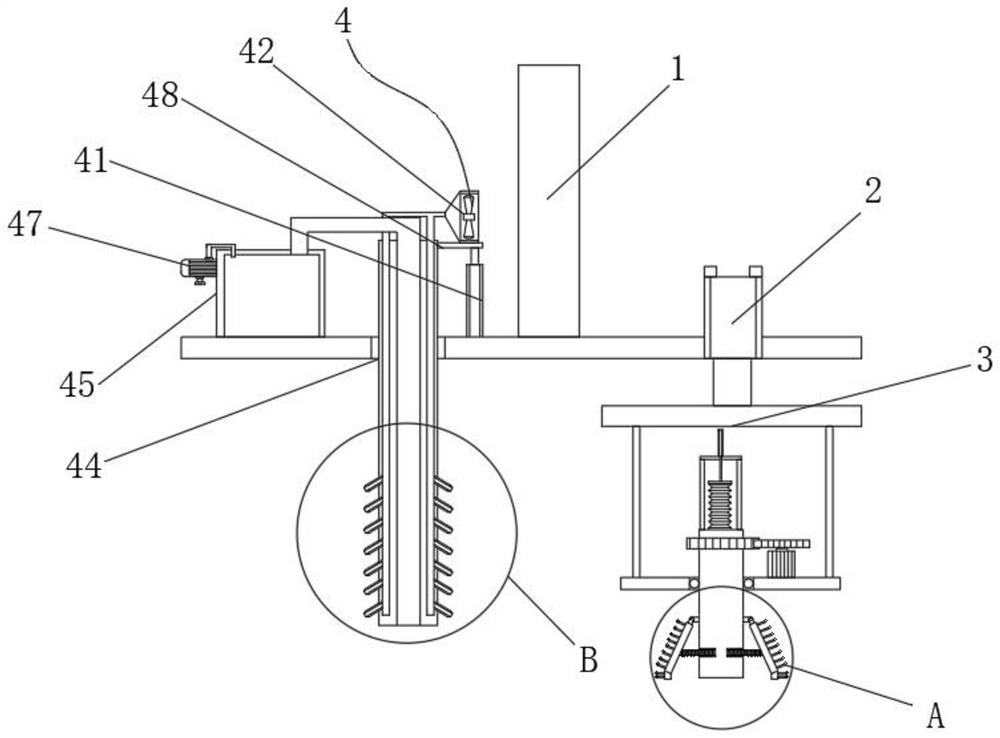

[0030] As an embodiment of the present invention, the polishing assembly 3 includes a lifting plate 31, a connecting column 32, an extruding cylinder 33, a support frame 34, an extruding plate 35, an extruding air bag 36, a driving gear 37, a fixed plate 38, a rotating Motor 39, hairbrush 310, telescopic frame 311, telescopic air bag 312, rotating column 313, cooperating gear 314 and contraction spring 315, the bottom side of hoisting plate 31 is welded with connecting column 32, and the bottom of connecting column 32 is welded with fixing pin. Plate 38, the inside of the fixed plate 38 is provided with a bearing seat, the rotating column 313 is fitted in the bearing seat through bearing fit, the top of the rotating column 313 is welded with a support frame 34, and the top of the support frame 34 is welded with an extruding cylinder 33 , the effect end of extrusion cylinder 33 is equipped with extruding plate 35, and the bottom side of extruding plate 35 is pasted with extrudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com