Manufacturing method for reducing optical fiber loss

A manufacturing method and optical fiber loss technology, applied in the direction of manufacturing tools, glass manufacturing equipment, etc., can solve problems such as imperfect optical fiber structure, molecular bond breakage in the optical fiber structure, scattering loss, etc., so as to improve the order of molecular arrangement and increase the longitudinal The length of the hot zone and the effect of reducing the drawing tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Longitudinal Hot Zone Length Screening Example

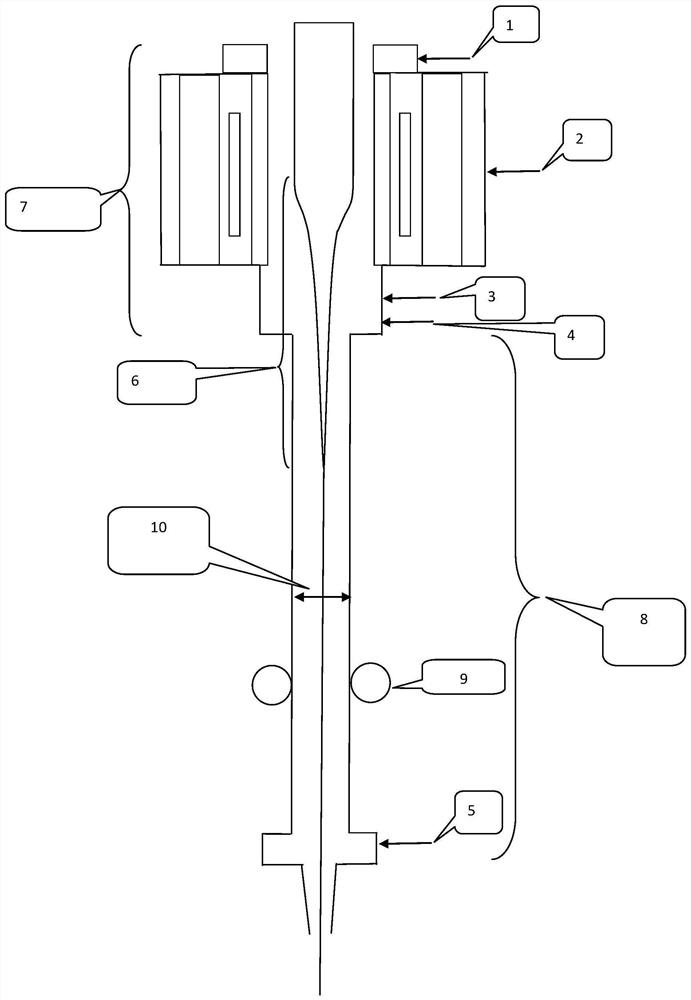

[0038] Such as image 3 As shown, the length of the hot zone of the existing heating furnace is generally 900-1000mm. The height of the original hot zone 7 of the heating furnace adopted by the applicant of the present invention is 960mm, and the loss of the output optical fiber is relatively high. The length setting gradient changes are 2000mm, 2100mm, 2200mm, ..., 4000mm, and the performance test is carried out on the final produced optical fiber. The results are shown in Figure 4 and Figure 5 shown.

[0039] From Figure 4 and Figure 5 It can be seen that the length of the increased longitudinal hot zone needs to exceed 2500mm, that is, the total length of the hot zone must be more than 3460mm to produce a positive improvement in the loss of the optical fiber. Theoretically, the longer the length of the vertical hot zone, the better the loss of the optical fiber. It is found in the test that when the length of ...

Embodiment 2

[0043] Such as image 3 As shown, the inert gas inlet 1 / 2 / 3 / 4 / 5 in the figure, a total of 5 positions are used to feed inert gas. After a long period of exploration, it is determined that the distance between the inlet hole and the highest point of the heating area is 50 ~70mm, 660~680mm, 875~895mm, 932~952mm, 4450~4470mm, the performance of the output optical fiber is the most stable; the flow rate of the inert gas is 3L / min~5L / min, 3L / min~4L respectively / min, 3L / min~5L / min, 5L / min~11L / min, 6L / min~9L / min. The average gas flow combinations are 4L / min, 3.5L / min, 4L / min, 8L / min, 7.5L / min.

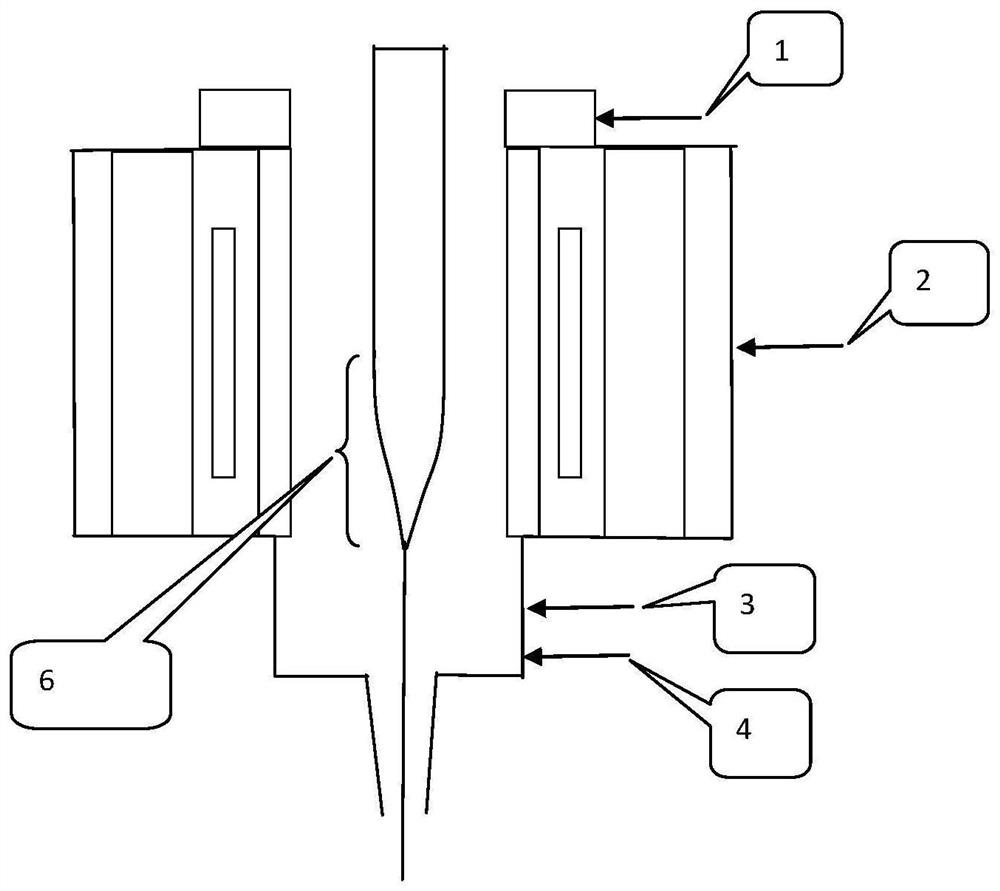

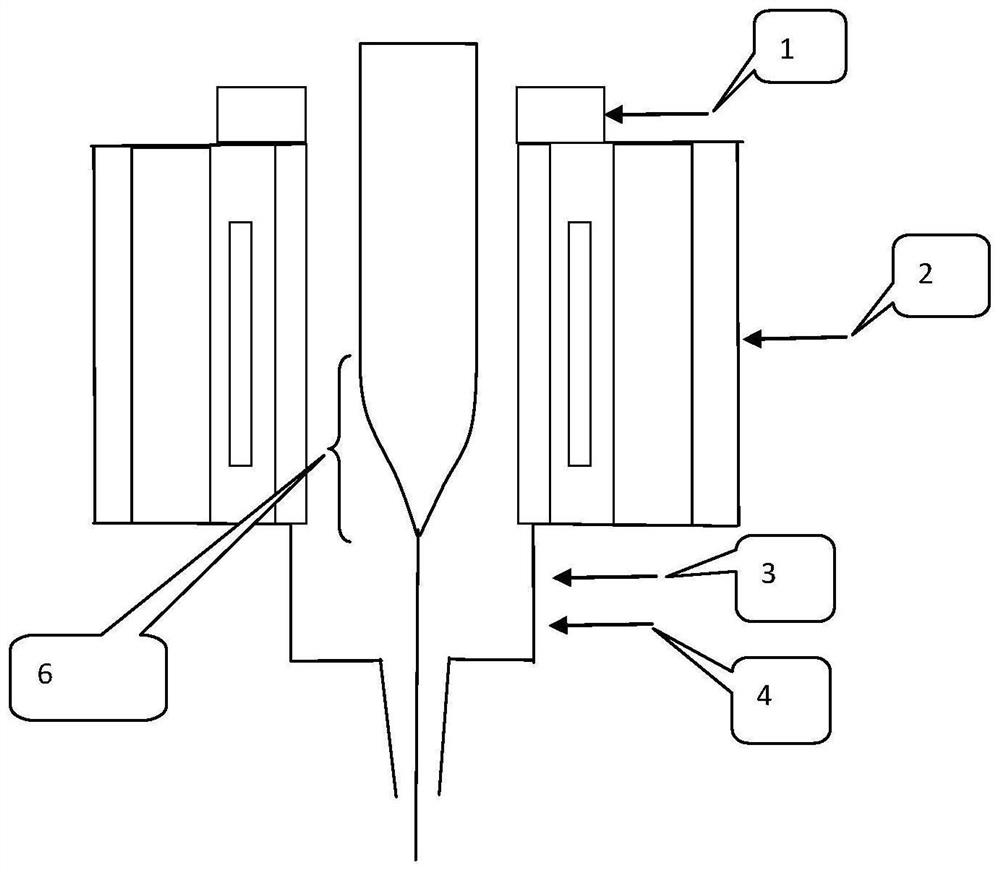

[0044] With the original heating furnace (such as figure 2 (shown) compared to: only the inert gas inlet 1 / 2 / 3 / 4 in the original heat zone 7, a total of 4 positions are fed with inert gas, and the flow rate of the feed is 5L / min~6L / min, 1.5L / min respectively ~2.5L / min, 2.5L / min~3.5L / min, 12L / min~14L / min, the average gas flow combination is 6L / min, 2L / min, 3L / min, 13L / min; The performance...

Embodiment 3

[0049] Such as image 3 It is shown that after the length of the longitudinal hot zone is determined, the gradient changes of the inner diameter 10 of the vertical growth hot zone are 30mm, 40mm, ..., 100mm respectively. After verification, the inner diameter of 40mm to 60mm meets the production requirements, and the inner diameter is too small. It is easy to be scrapped due to poor strength, and when the inner diameter is too large, more gas needs to be introduced. Considering the economy, the final inner diameter of the hot zone is determined to be 50mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com