Optical glass, preparation method thereof and optical element

A technology of optical glass and optical components, applied in the direction of optical components, glass manufacturing equipment, glass pressing, etc., can solve the problems of unfavorable optical terminal products such as miniaturization, light weight, unfavorable transition temperature, high glass density, etc., and achieve chemical stability Excellent, simple preparation method, low dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] The present invention also provides a method for preparing the optical glass according to the present invention, which includes the step of mixing the components of the optical glass.

[0067] Specifically, the preparation method of the optical glass according to the present invention includes the following steps: weighing them according to the specified ratio, mixing them into batch materials, melting them in a crucible made of platinum at a temperature of 1220°C to 1270°C, and waiting After the raw materials are melted into molten glass, the temperature is raised to 1290°C-1340°C and a stirrer made of platinum material is turned on for stirring and homogenization, and the stirring time is controlled at 5-10 hours. After the stirring is completed, raise the temperature to 1340°C-1380°C and keep it warm for 5-10 hours to clarify and make the bubbles fully float up, then lower the temperature to 1050°C-1150°C to pour or leak into the molding mold or molded, and finally th...

Embodiment 1-14

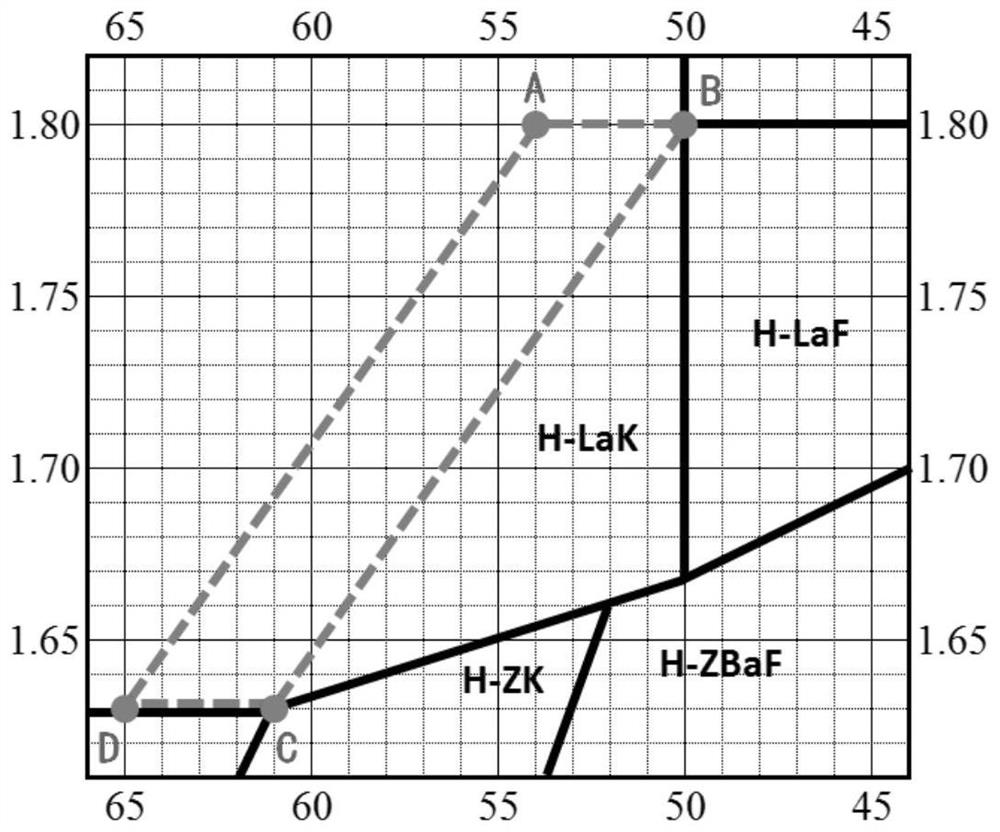

[0085] Embodiment 1~14 among the table 1-3 is that the present invention is used for illustrating and obtains refractive index (nd) and Abbe's number (υd) in the υd-nd coordinate system by A (1.80,54), B (1.80, 50 ), C (1.63, 61), D (1.63, 65) the embodiment of the lanthanum crown optical glass in the region formed by four points.

[0086] The preparation methods of the optical glasses of Examples 1-14 and Comparative Examples 1-3 of the present invention are as follows: Weigh them according to the specified ratio, mix them into batch materials, and melt them in a crucible made of platinum at a temperature of 1250°C After the raw materials are melted into molten glass, the temperature is raised to 1320°C and the stirrer made of platinum material is turned on to stir and homogenize, and the stirring time is controlled at 8h. After the stirring is completed, raise the temperature to 1360°C and hold it for 7 hours for clarification, so that the bubbles fully float up, then lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com