High-quality microwave dielectric ceramic powder, microwave dielectric ceramic, preparation method and application

A microwave dielectric ceramic, high-quality technology, used in waveguides, waveguide-type devices, resonators, etc., can solve problems such as unsatisfactory quality factor and high requirements for microwave dielectric ceramic materials, and achieve improved electrical performance, quality factor, and reduction. The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

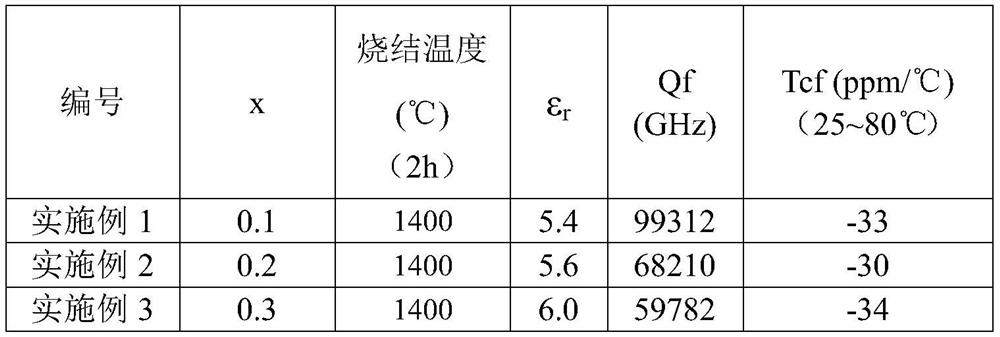

[0023] The raw materials for the preparation of the high-quality microwave dielectric ceramics include magnesium oxide, nickel oxide, aluminum oxide, and silicon dioxide, and their mass ratios are based on the composition expression (Mg 1-x Ni x ) 2 al 4 Si 5 o 18 Calculate the molar ratio of each element.

[0024] The present invention also provides a method for preparing the above-mentioned high-quality microwave dielectric ceramics, comprising the following steps:

[0025] (1) According to the composition expression (Mg 1-x Ni x ) 2 al 4 Si 5 o 18 The molar ratio of each element in MgO powder, NiO powder, Al 2 o 3 Powder, SiO 2 The powder is batched, mixed fully and ball milled, dried and sieved after ball milling, and then put into a corundum crucible for roasting to obtain a pre-fired powder; wherein, in the composition expression (Mg 1-x Ni x ) 2 al 4 Si 5 o 18 Among them, x represents the molar ratio, and x=0.1~0.5;

[0026] (2) fully ball-milling th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com